7. Adjustment of the throttle cable tension may be

required. If so, loosen the adjusting nut (top nut) on

the throttle cable receiver (Figure 7) and loosen or

tighten the locking nut (bottom nut). Retighten

adjusting nut.

Figure 7. Throttle Cable Receiver Adjustment

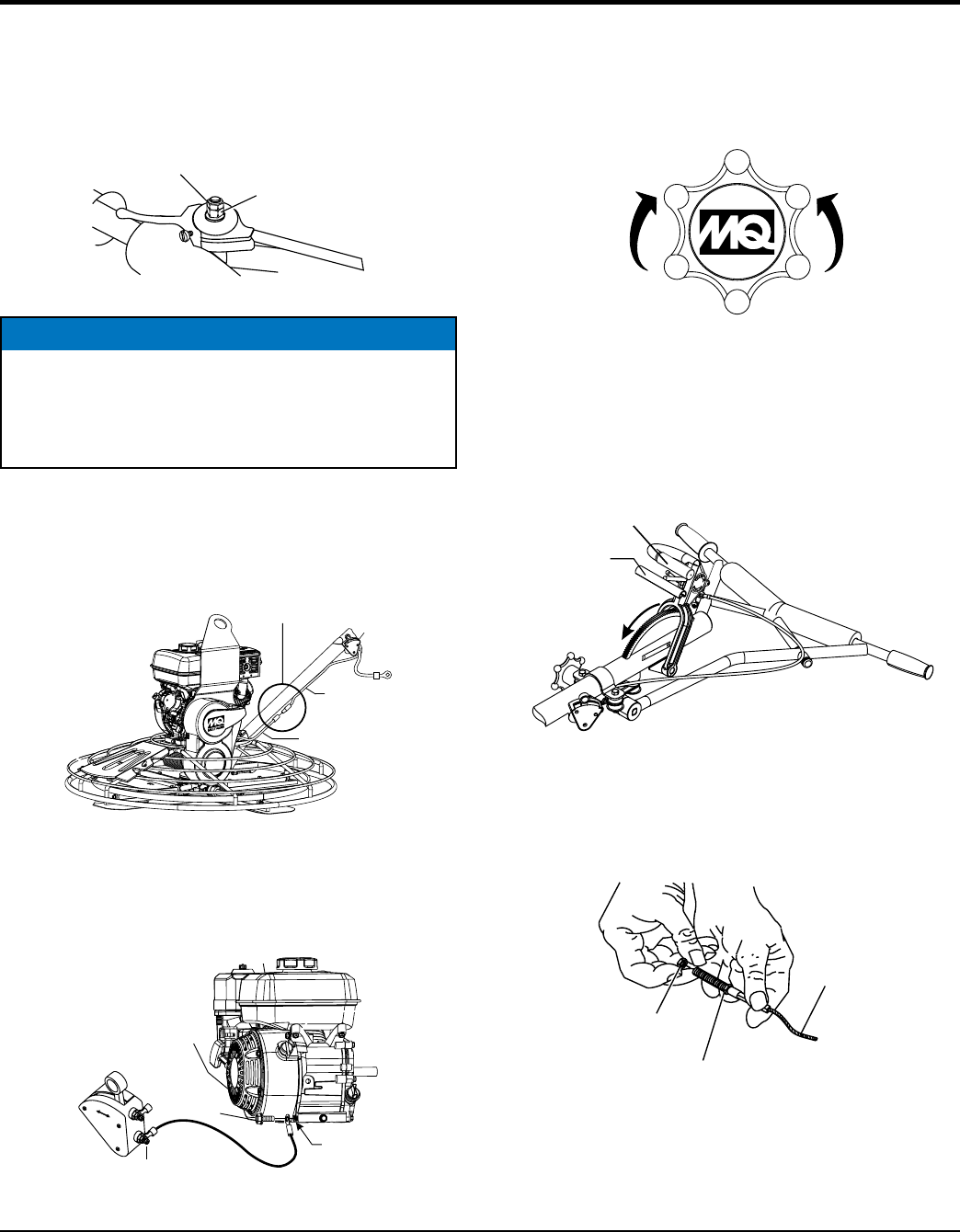

Safety Stop Switch Connection

1. Connect the black tail wire from the engine to the black

safety stop wire from the centrifugal stop switch as

shown in Figure 8.

Figure 8. Safety Stop Switch Connection

2. k Remove the existing bottom mounting screw on the

recoil starter cover (Figure 9) and connect the bottom

wire from the centrifugal stop switch to this engine

ground point.

Figure 9. Engine Ground Point

ADJUSTING

NUT (TOP)

LOCKING NUT

(BOTTOM)

NOTICE

If the throttle lever does not return to the "neutral"

position with throttle backed off, loosen adjuster nut 1/2

turn at a time, tighten and recheck. Readjust throttle

tension as necessary.

SAFETY STOPWIRE

CONNECTION POINT

BLACK

TAIL WIRE

TOP SAFETY

STOP WIRE

CENTRIFUGAL

STOP SWITCH

ON

OFF

CENTRIFUGAL

STOPSWITCH

BOTTOM

EXISTING

SCREW

FUELTANK

ENGINE

GROUND

POINT

RECOIL

STARTER

COVER

ASSEMBLY AND INSTALLATION

Pitch Cable Installation

1. For Standard Handle models expose the pitch cable

to maximum by turning the blade pitch star wheel

(Figure 10) fully counterclockwise for no pitch (blades

flat).

Figure 10. Blade Pitch Star Wheel

(Standard Handle)

2. For Quick Pitch™ Handle models expose the pitch

cable to maximum by grasping the T-handle (Figure 11),

then squeezing the trigger lock and pushing the

T-handle forward for no pitch (blades flat).

Figure 11. Blade Pitch T-Handle

(Quick Pitch™ Handle)

3. Remove brass set nut #1 from the blade pitch cable

end as shown in (Figure 12).

Figure 12. Blade Pitch Cable

4. Thread brass set nut #2 (Figure 12) towards the cable

as far as possible.

INCREASE

BLADE PITCH

(CW)

DECREASE

BLADE PITCH

(CCW)

T-HANDLE

TRIGGER

(SQUEEZE)

NO PITCH

FOR

WARD

BLADE

PITCH

CABLE

BRASS SET

NUT #1

BRASS SET

NUT #2