MAINTENANCE AND REPAIR INSTRUCTIONS

9

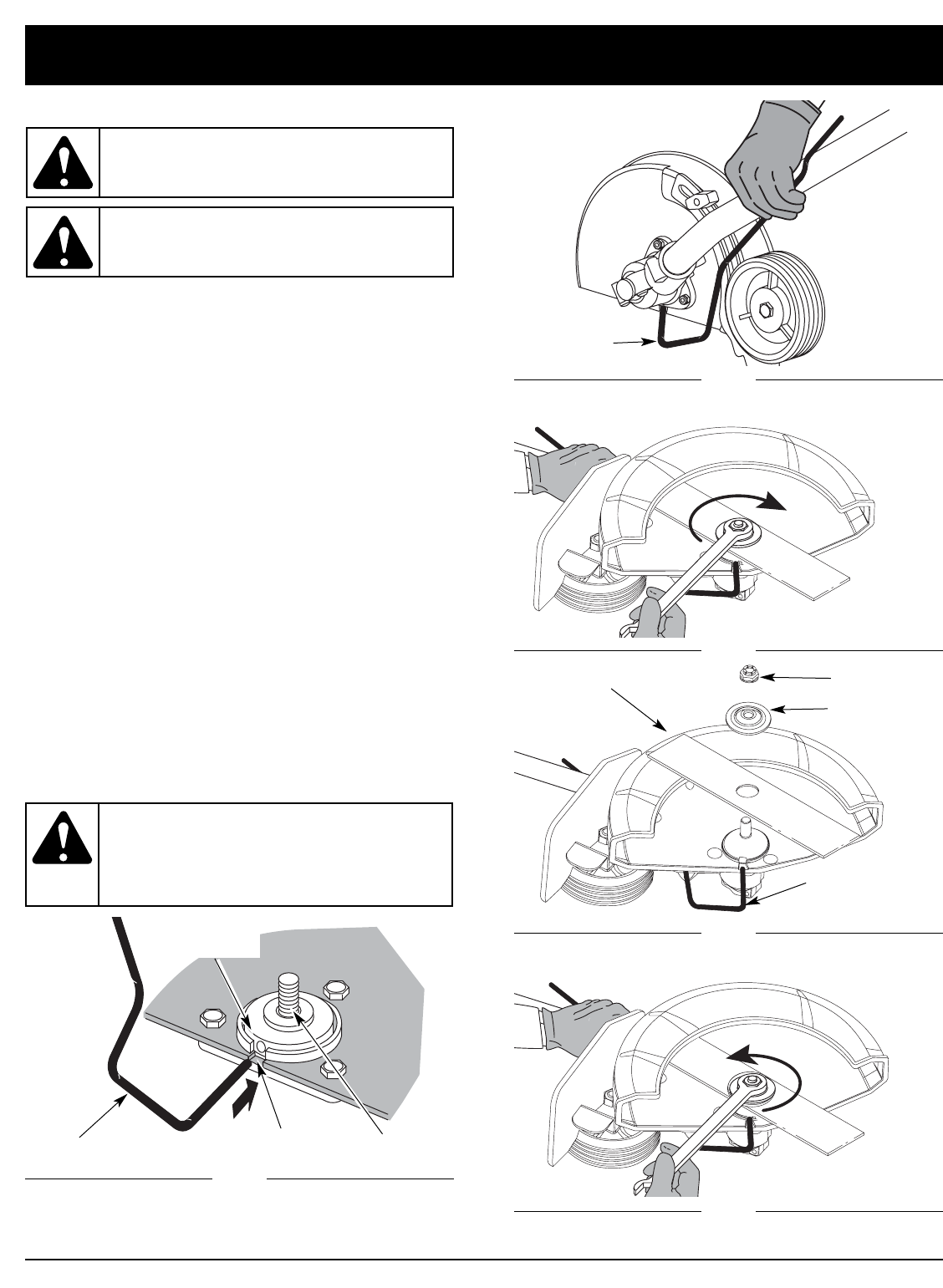

Fig. 10

Fig. 9

Fig. 8

Fig. 11

EDGER BLADE REPLACEMENT

1. Line up the hole in output shaft with the locking rod

slot. Insert the locking rod through the slot into the

output shaft hole (Fig. 7).

2. Hold the locking rod in place by grasping it next to

the boom of the unit (Fig.8).

3. While holding the locking rod, loosen the nut on the

blade by turning it clockwise with a 5/8 inch wrench

(Fig. 9). Remove the nut, retaining washer and blade.

Keep the nut and blade retainer for installation.

4. Install the new blade, blade retainer, and nut

(Fig. 10). Insert the locking rod through the slot into

the output shaft hole. Make sure that the blade stays

flat and centered against the output shaft while

tightening the lock nut counterclockwise (Fig. 11).

5. If you have a torque wrench, tighten the nut to

325-335 in.•lbs (37-38 N•m), while holding the

locking rod in the slot.

If you do not have a torque wrench, hold the locking

rod in the slot. Rotate the nut counterclockwise with

a 5/8 inch closed-ended or socket wrench, until the

nut presses against the washer and the blade is

snug. Make sure the blade assembly is installed

correctly, then rotate the nut an additional 1/4-1/2

turn (Fig. 11).

6. Remove the locking rod.

Fig. 7

Locking Rod

Locking Rod

Locking Rod

Blade Retainer

Lock Nut

Loosen

Tighten

Edger Blade

Output Shaft

Hole

Locking Rod Slot

Output Shaft

WARNING: To avoid serious personal injury,

always wear gloves while handling, removing

or installing the blade.

WARNING: Verify the blade is flat against the

output shaft after the nut is tightened. If the

blade is off-center, the unit will be damaged

by vibration, and the blade may fly off, which

can cause serious personal injury.

WARNING:

The gear housing gets hot after long

periods of use. To avoid serious personal injury,

do not touch the housing until it has cooled.