22

Thread the idler adjustment rod inward or outward to

lengthen or shorten the travel of the double-idler

bracket until proper adjustment is achieved.

• Reassemble by following the above steps in

reverse order.

CUTTING BLADES

WARNING: Cutting blades are sharp.

Always protect hands by wearing heavy

leather work gloves to grasp blades.

The blades may be removed for sharpening or

replacement as follows.

• Remove the deck from beneath the tractor,

(refer to DECK REMOVAL earlier in this

section for detailed instructions) then gently

flip the deck over to expose its underside.

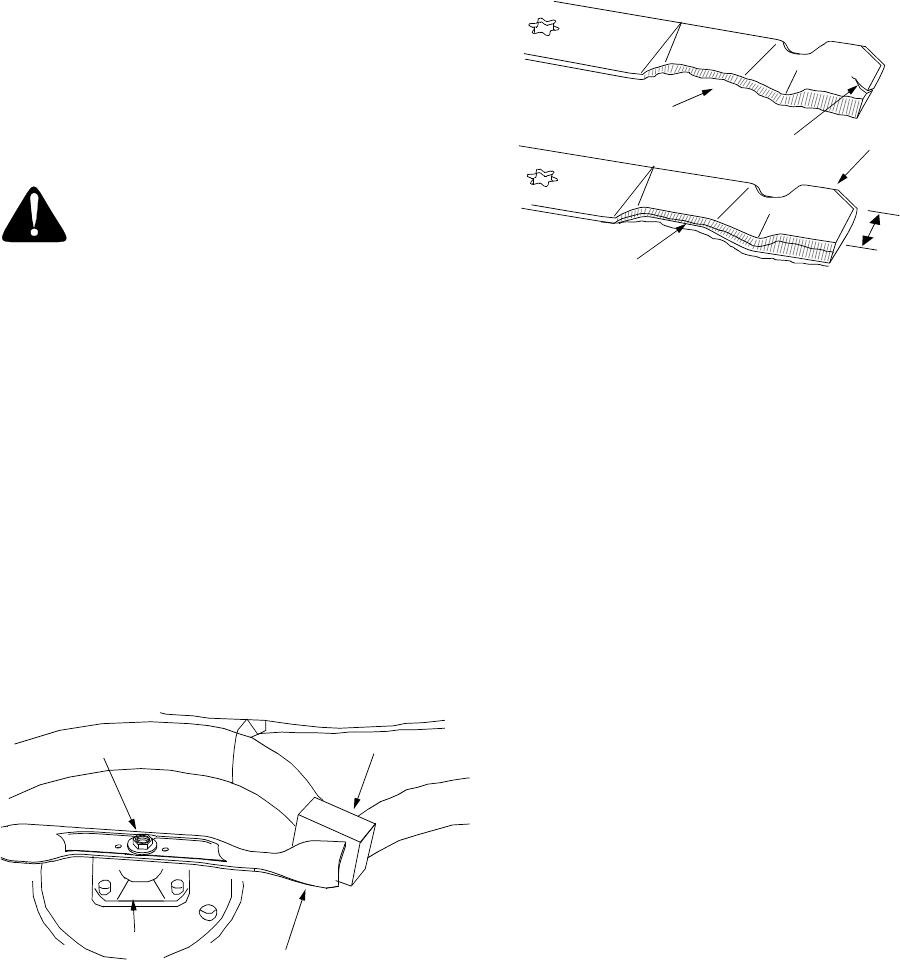

• Place a block of wood between the center

deck housing baffle and the cutting blade to

act as a stabilizer. See Figure 20.

• Use a 15/16" wrench to remove the hex flange

nut that secures the blade to the spindle

assembly. See Figure 20.

NOTE:

The hex flange nut has a right-handed

thread pattern. Do NOT attempt to force the nut in

the incorrect direction. Doing so may damage the

nut and create a safety hazard.

Figure 20

To properly sharpen the cutting blades, remove

equal amounts of metal from both ends of the blades

along the cutting edges. See Figure 21.

Sharpen the cutting edge straight across, parallel to

the trailing edge, at a 25° to 30° angle. See Figure

21.

IMPORTANT:

If the cutting edge of the blade has

already been sharpened to within 5/8" of the wind

wing radius, or if any metal separation is present,

replace the blades with new ones. See Figure 21.

Figure 21

It is extremely important that each cutting blade

edge be ground equally to maintain proper blade

balance. An unbalanced blade will cause excessive

vibration when rotating at high speeds, may cause

damage to the tractor and result in personal injury.

The blade can be tested by balancing it on a round

shaft screwdriver. Grind metal from the heavy side

until it balances evenly.

When replacing the blade, be sure to install the

blade with the side of the blade marked ‘‘Bottom’’ (or

with a part number stamped in it) facing the ground

when the mower is in the operating position.

IMPORTANT:

Use a torque wrench to tighten the

blade spindle hex flange nut to between 70 foot-

pounds and 90 foot-pounds.

BATTERY

The battery is sealed and is maintenance-free. Acid

levels cannot be checked.

• Always keep the battery cables and terminals

clean and free of corrosive build-up.

• After cleaning the battery and terminals, apply

a light coat of petroleum jelly or grease to the

terminals and over the positive terminal boot.

• Always keep the boot positioned over the

positive terminal to prevent shorting.

IMPORTANT:

If removing the battery for any

reason, disconnect the NEGATIVE (Black) wire from

it’s terminal first, followed by the POSITIVE (Red)

wire. When re-installing the battery, always connect

the POSITIVE (Red) wire its terminal first, followed

by the NEGATIVE (Black) wire. Be certain that the

wires are connected to the correct terminals.

reversing them could change the polarity and cause

damage to your engine’s alternating system.

Cutting Blade

Block of Wood

Spindle

Assembly

Hex Flange Nut

5

/

8

"

m

i

n

i

m

u

m

Blade Separation

Worn Blade Edge

Wind Wing

Sharpen Edge Evenly