14

6

Maintaining

Your Snow

Thrower

WARNING

Before lubricating,

repairing, or inspect-

ing, disengage all

controls and stop

engine. Wait until all

moving parts have

come to a complete

stop.

Keep all grease and oil

off of the rubber friction

wheel and aluminum

drive plate.

Engine

Refer to the separate engine manual packed with your

unit for all engine maintenance.

Lubrication

Engine

Refer to the separate engine manual packed with your

unit for all engine lubrication instructions.

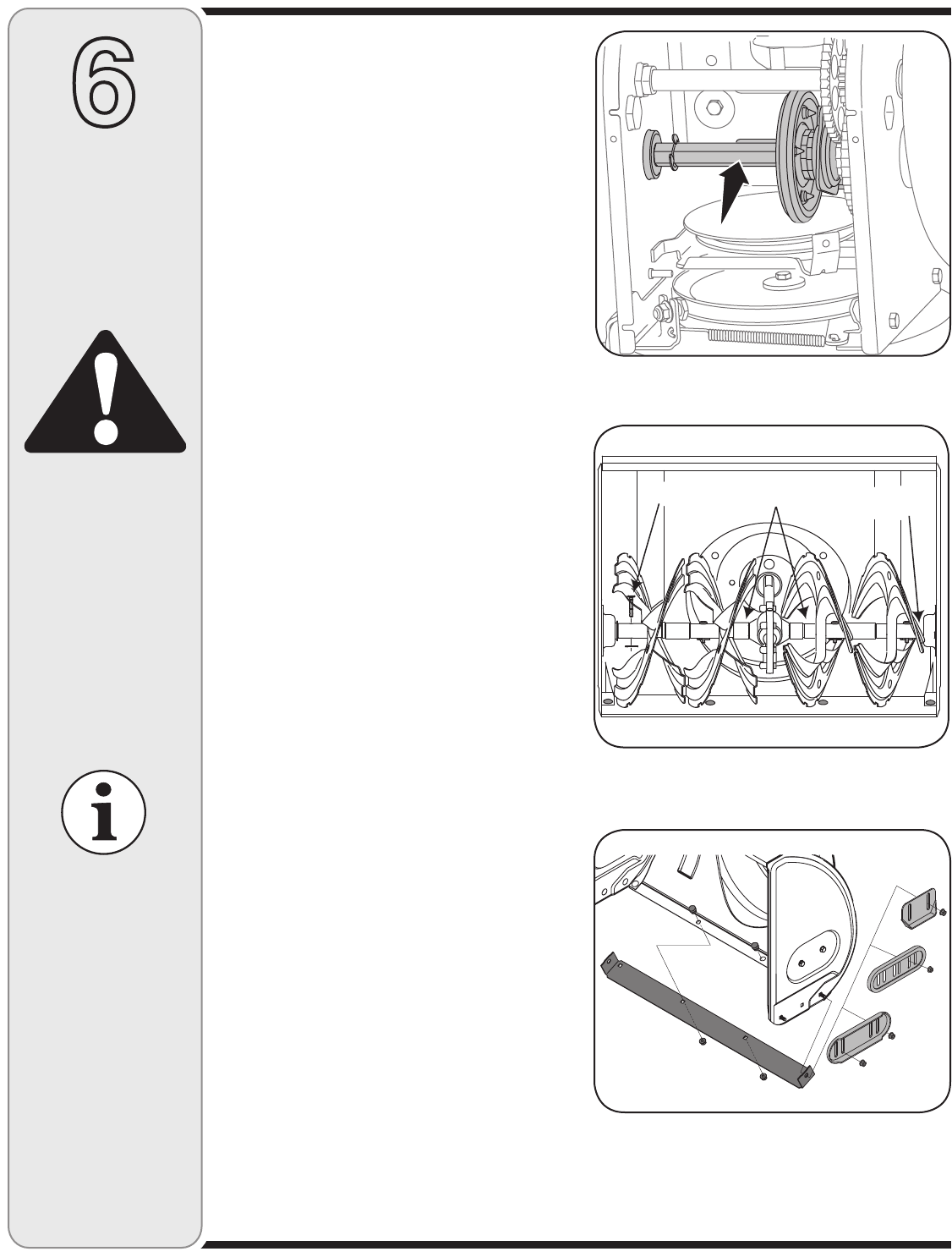

Gear Shaft

The gear (hex) shaft should be lubricated at least once

a season or after every 25 hours of operation.

1. Carefully pivot the snow thrower up and forward so

that it rests on the auger housing.

2. Remove the lower frame cover by removing the two

screws which secure it.

3. Apply a light coating of an all-weather multi-purpose

oil to the hex shaft. See Figure 6-1.

NOTE: Avoid getting oil on rubber friction wheel and

aluminum drive plate.

Wheels

At least once a season, remove both wheels. Clean and

coat the axles with a multipurpose automotive grease

before reinstalling wheels.

Chute Directional Control (optional)

Once a season, the joystick should be lubricated with

petroleum jelly, linseed oil, mineral oil, paraffin wax or

3-in-1 oil.

Auger Shaft

At least once a season, remove the shear pins on auger

shaft. Spray lubricant inside shaft, around the spacers.

Also lubricate the flange bearings found at either end of

the shaft. See Figure 6-2.

Shave Plate and Skid Shoes

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. They should be

checked periodically and replaced when necessary.

To remove skid shoes:

1. Remove the four carriage bolts and hex flange nuts

which secure them to the snow thrower.

2. Reassemble new skid shoes with the four carriage

bolts (two on each side) and hex flange nuts. Refer

to Figure 6-3.

To remove shave plate:

1. Remove the carriage bolts and hex nuts which attach

it and the skid shoes to the snow thrower housing.

2. Reassemble new shave plate, making sure heads of

carriage bolts are to the inside of housing. Tighten

securely.

Figure 6-1

Figure 6-2

3HEAR0IN

"EARING

3PACERS

Figure 6-3