11

Replacing the Edger Blade

WARNING: The edger blade is sharp. Wear

leather work gloves to protect your hands

when working around the edger blade.

WARNING: Disconnect the spark plug wire

and ground against engine before

performing the following steps.

• Working in front of the edger, loosen the flange lock

nut on top of frame, allowing the idler pulley

assembly to pivot slightly out from the frame. See

Figure 16.

• With your other hand, carefully reach under the rear

of the unit and remove the belt from around the

engine flywheel pulley.

• Remove the spindle sheaves belt guard by

removing the two self-tapping screws which secure

it to the blade plate assembly. See Figure 11.

• Use two wrenches (one wrench to prevent the hex

bolt head from spinning and the other to remove the

hex lock nut and bell washer) to remove the edger

blade. Refer to Figure 12.

• Remove and discard the edger blade but retain the

bell washer and hex lock nut.

• Install the replacement edger blade, the bell

washer (cupped side facing inward) and the hex

lock nut removed earlier.

IMPORTANT:

Use a torque wrench to tighten the hex

lock nut to between 37 foot-lbs. and 50 foot-lbs.

• Reinstall the spindle belt guard with the self tapping

screws removed earlier.

• Carefully place the drive belt back onto the engine

flywheel pulley, and retighten the flange lock nut on

the top of the frame.

IMPORTANT:

Make certain that the drive belt is seated

correctly on the blade spindle and that it is riding

smoothly on the spindle sheaves and is not pinched

between them. Repeat the first three steps if the belt is

pinched.

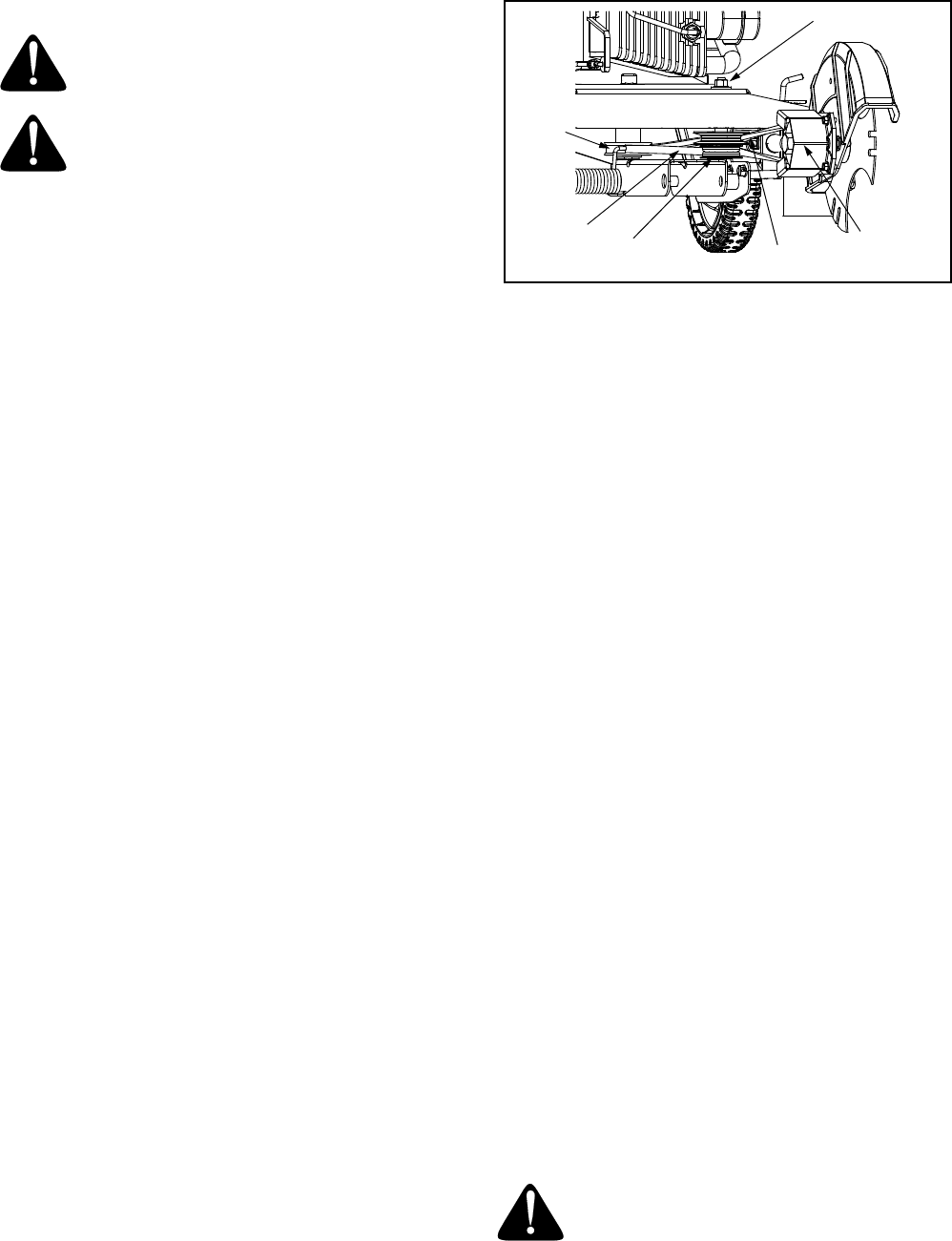

Replacing the Drive Belt

IMPORTANT:

To aid in reassembly, note the orientation

of the drive belt on the two idler pulleys and the engine

flywheel pulley prior to performing the following steps.

Refer to Figure 16.

Figure 16

The edger drive belt is subject to wear and should be

replaced if any signs of cracking, shredding or rotting

are present. To replace the belt, proceed as follows:

• Working in front of the edger, loosen the flange lock

nut on top of frame, allowing the idler pulley

assembly to pivot slightly out from the frame. See

Figure 16.

• With your other hand, carefully reach under the rear

of the unit and remove the belt from around the

engine flywheel pulley.

• Remove the spindle sheaves belt guard by

removing the two self-tapping screws which secure

it to the blade plate assembly. See Figure 11.

• Carefully remove the belt from off of the pulleys,

again making sure to note the orientation of the

belt. Discard the belt.

Install the replacement belt (Part No. 754-04032) in the

same configuration that the original belt was routed as

follows:

• Working from the front of the edger, place the belt

onto the spindle sheaves, route it back onto the two

idler pulleys, and then place it onto the engine

flywheel pulley.

IMPORTANT:

Make certain that the “V” side of the belt is

seated into the top pulley and the flat side of the belt is

seated into the bottom pulley. See Figure 16.

• Reinstall the spindle sheaves belt guard with the

self tapping screws removed earlier.

• Make certain that the drive belt is on the engine

flywheel pulley and idler pulleys, and retighten the

flange lock nut on the top of the frame.

IMPORTANT:

Make certain that the drive belt is seated

correctly and that it is riding smoothly on the spindle

sheaves and is not pinched between them. Repeat the

first three steps if the belt is pinched.

WARNING: Never operate the edger without

the spindle sheaves belt guard in place.

Flat Side

of Belt

“V” Side

of Belt

Spindle Sheaves

Belt Guard

Flange Lock Nut

Idler Pulley

Assembly

Engine

Flywheel

Pulley