5

SECTION 2: ASSEMBLING YOUR TILLER

NOTE: This operator’s manual covers various models

of tillers. The units illustrated may vary slightly from

your unit. Follow only those instructions which pertain

to your model number.

NOTE: References to right or left side of the tiller are

determined from behind the unit in the operating

position.

To Remove Unit From Carton

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton.

• Remove loose parts included with unit (i.e.,

operator’s manual, etc.).

• Cut corners and lay carton down flat.

• Remove packing material.

• Roll or slide unit out of carton. Check carton

thoroughly for loose parts.

• Extend control cable and lay on the floor. Be careful

not to bend or kink control cable.

IMPORTANT:

This unit is shipped without gasoline or oil

in the engine. Be certain to service engine with gasoline

and oil as instructed in the separate engine manual

before operating your machine.

Loose Parts In Carton

Depth Stake

Handle Assembly

Shift Rod

NOTE: All hardware needed for assembly is attached

to the loose parts or the tiller.

Before Assembly

WARNING: Disconnect the spark plug wire

and ground it against the engine to prevent

unintended starting.

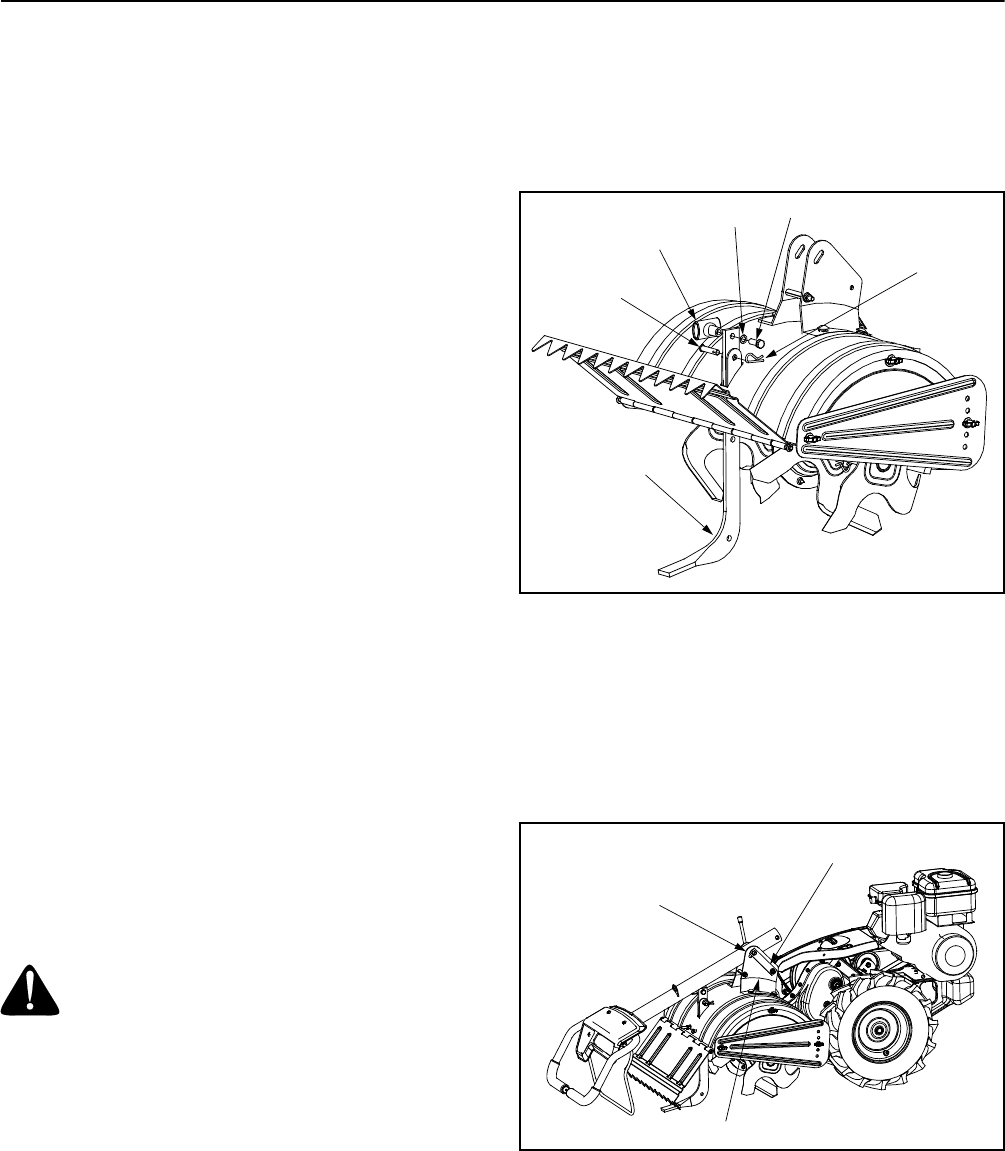

Attaching Depth Stake

• Tip the tiller forward so it rests on front

counterweight.

• Unthread the “T” knob from the top of the depth

stake and remove the flat washer and hex bolt.

Remove the hairpin clip from the clevis pin.

See Figure 1.

• Raise the tine shield hinge flap assembly and insert

the depth stake assembly in the slot (under the tine

shield) and up through the tine shield assembly.

• Insert clevis pin through the tine shield and depth

stake assemblies. Secure with hairpin clip.

• Insert hex bolt into the top hole of the depth stake

assembly. Place flat washer on the hex bolt and

thread “T” knob onto the hex bolt. Tighten securely.

See Figure 1.

• Tip the tiller back down so it rests on the tines.

Figure 1

Attaching Handle Assembly

• Remove the handle adjustment crank, flange nut,

retainer bracket, shoulder bolt, and lock nut from

the pivot bracket.

• Place the handle assembly in position in the handle

pivot bracket lining the upper holes in the handle

with the slots in the pivot bracket. See Figure 2.

Figure 2

• Lift up the handle assembly and align the bottom

holes in the handle assembly with the holes in the

pivot bracket. Insert shoulder bolt from the left side

of unit through the pivot bracket and the retainer

bracket on the right hand side of the unit.

See Figure 3.

T-Knob

Flat Washer

Hex Bolt

Hairpin Clip

Clevis Pin

Depth Stake

Pivot Bracket

Handle Adjustment Crank

and Flange Nut

Retainer Bracket,

Shoulder Bolt, & Lock Nut