5

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Switch action (Fig. 1)

CAUTION:

• Before plugging in the tool, always check to see that

the slide switch actuates properly and returns to the

“OFF” position when the rear of the slide switch is

depressed.

• Switch can be locked in “ON” position for ease of oper-

ator comfort during extended use. Apply caution when

locking tool in “ON” position and maintain firm grasp on

tool.

To start the tool, slide the slide switch toward the “I (ON)”

position. For continuous operation, press the front of the

slide switch to lock it.

To stop the tool, press the rear of the slide switch, then

slide it toward the “O (OFF)” position.

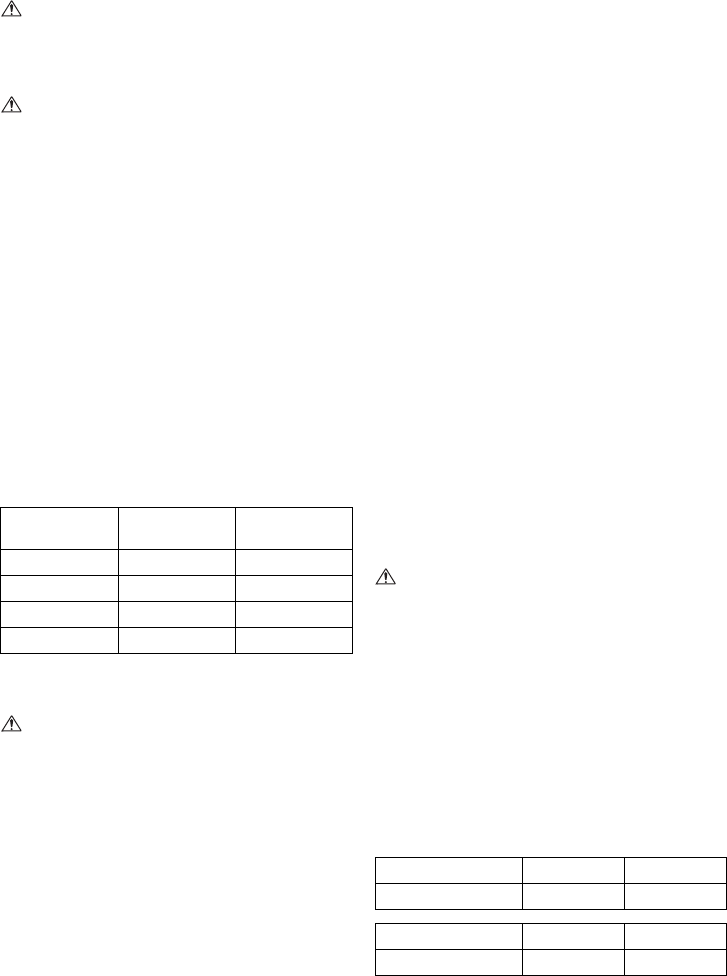

Permissible shearing thickness (Fig. 2)

The groove on the yoke serves as a thickness gauge for

shearing mild or stainless steel plate. If the material fits

within the groove, it is shearable.

The thickness of materials to be sheared depends upon

the type (strength) of the material. The maximum shear-

ing thickness is indicated in the table below in terms of

various materials. Attempting to shear materials thicker

than indicated will result in tool breakdown and/or possi-

ble injury. Keep within the thickness shown in the table.

006425

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Blade inspection

Before using the tool, check the blades for wear. Dull,

worn blades will result in poor shearing action, and the

service life of the tool will be shortened.

Rotating or replacing blades (Fig. 3, 4, 5, 6, 7 & 8)

Both the upper and lower blades have four cutting edges

on each side (the front and back). When the cutting edge

becomes dull, rotate both the upper and the lower blades

90° to expose new cutting edges.

When all eight edges are dull on both the upper and

lower blades, replace both blades with new ones. Each

time blades are rotated or replaced, proceed as follows.

Remove the blade securing bolts with the hex wrench

provided and then rotate or replace the blades.

Some tools have one washer between the upper blade

and the blade holder. When the tool has the washer, be

sure to use the thin washer when reassembling.

NOTE:

• No thin washers are used for the lower blade.

Install the upper blade and tighten the upper blade secur-

ing bolt with the hex wrench. Press up on the upper

blade while tightening it.

After securing the upper blade, be sure that there is no

gap left between the upper blade and the beveled sur-

face of the blade holder.

When installing the lower blade onto the yoke, the lower

blade should be pressed against the yoke so as to be

contacting the beveled portions A and B of the yoke and

the tip C of the lower blade positioning screw while you

tighten the lower blade securing bolt. There must be no

clearance between A, B and C during installation.

NOTE:

• The lower blade positioning screw is factory-assem-

bled. Do not tamper with it.

OPERATION

Holding material and shearing method (Fig. 9)

WARNING:

• Before operating the tool, be sure to firmly tighten the

upper blade securing bolt and the lower blade securing

bolt. Loosen bolts may cause blades coming off, result-

ing in a serious injury.

• When cutting, always place the shear on the workpiece

so that the material cut away is positioned on the right

side to the operator.

The materials for cutting should be fastened to the work-

bench by means of workholders.

Always hold the tool firmly with one hand on housing. Do

not touch the metal part.

Keep the shear moving parallel with the material.

Maximum cutting width (Fig. 10)

Stay within the specified maximum cutting width (A):

Case of length 1,800 mm.

006430

Material

Tensile Strength

(N/mm

2

)

Max. cutting

thickness (mm)

Mild steel (A) 400 1.6 (16 ga)

Hard steel (B) 600 1.2 (18 ga)

Stainless steel 800 0.8 (22 ga)

Aluminum plate 200 2.5 (13 ga)

Mild steel (thickness) 1.6 mm Under 1.2 mm

Max. cutting width (A) 100 mm No limit

Stainless (thickness) 1.2 mm Under 1.0 mm

Max. cutting width (A) 80 mm No limit