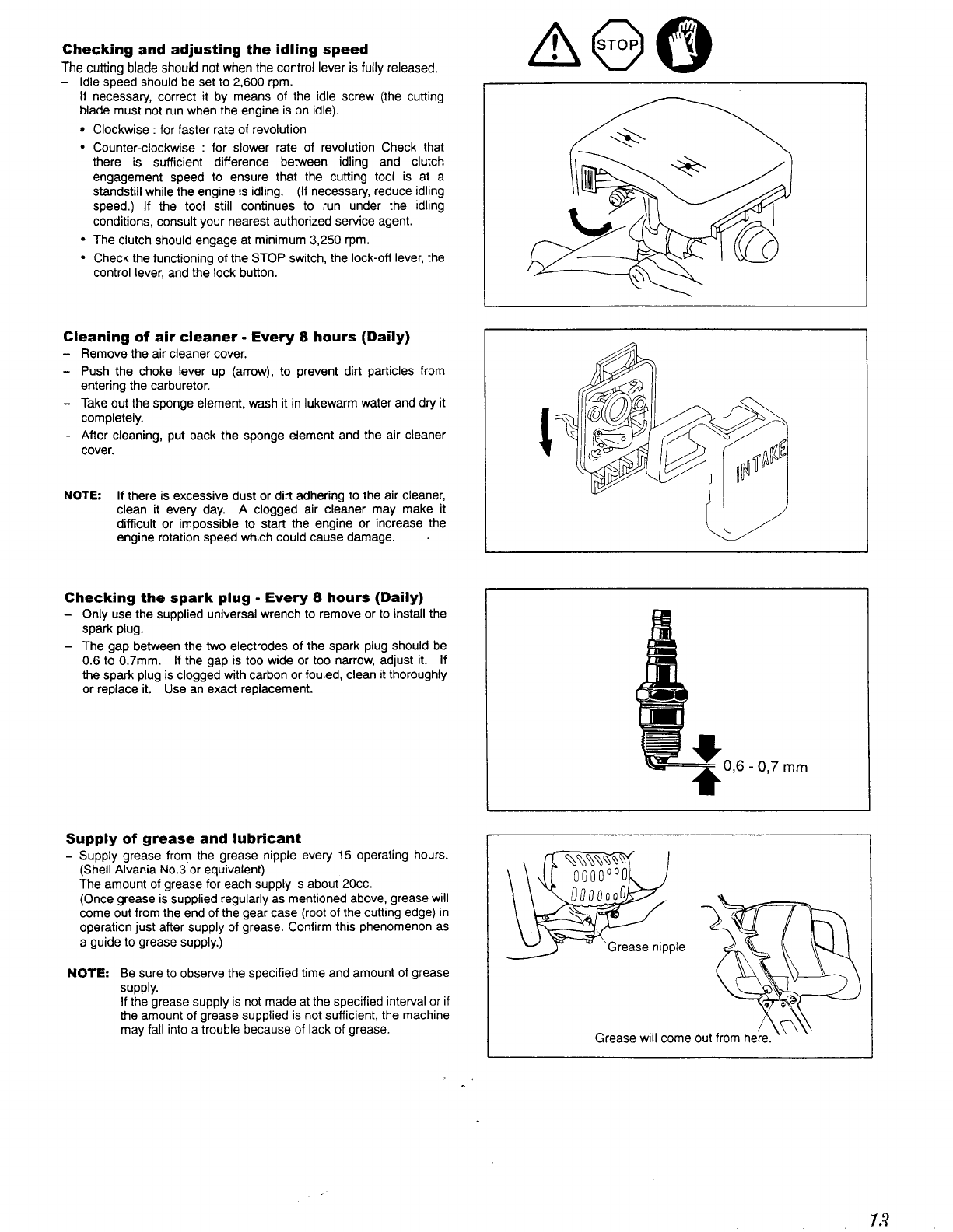

Checking and adjusting the idling speed

The

cutting

blade should

not

when the control lever

is

fully released.

-

Idle

speed should be set to

2,600

rpm.

If

necessary, correct it by means

of

the idle screw (the cutting

blade must not run when the engine

is

on idle).

Clockwise

:

for

faster rate

of

revolution

Counter-clockwise

:

for

slower rate

of

revolution Check that

there

is

sufficient difference between idling and clutch

engagement speed to ensure that the cutting tool

is

at

a

standstill while the engine

is

idling.

(If

necessary, reduce idling

speed.)

If

the tool still continues to

run

under the idling

conditions, consult your nearest authorized service agent.

The clutch should engage at minimum

3,250

rpm.

Check the functioning

of

the

STOP

switch, the lock-off lever, the

control lever, and the

lock

button.

Cleaning

of

air cleaner

-

Every

8

hours (Daily)

-

Remove the

air

cleaner cover.

-

Push the choke lever up (arrow), to prevent dirt particles from

entering the carburetor.

-

Take

out the sponge element, wash it in lukewarm water and dry it

completely.

-

After cleaning, put back the sponge element and the

air

cleaner

cover.

NOTE

If

there

is

excessive dust

or

dirt adhering

to

the

air

cleaner,

clean it every day.

A

clogged

air

cleaner may make it

difficult or impossible to start the engine or increase the

engine rotation speed which could cause damage.

.

Checking the spark plug

-

Every

8

hours (Daily)

-

Only use the supplied universal wrench to remove

or

to install the

spark plug.

-

The gap between the two electrodes

of

the spark plug should be

0.6

to 0.7mm.

If

the gap

is

too wide

or

too narrow, adjust it.

If

the spark plug

is

clogged with carbon or fouled, clean it thoroughly

or replace it.

Use

an exact replacement.

Supply

of

grease and lubricant

-

Supply grease from the grease nipple every

15

operating hours.

(Shell Alvania

No.3

or

equivalent)

The amount

of

grease

for

each supply

is

about 20cc.

(Once grease

is

supplied regularly

as

mentioned above, grease will

come out from the end

of

the gear

case

(root

of

the cutting edge) in

operation just after supply

of

grease. Confirm this phenomenon

as

a

guide to grease supply.)

NOTE:

Be sure to observe the specified time and amount

of

grease

supply.

If

the grease supply

is

not made at the specified interval

or

if

the amount

of

grease supplied

is

not sufficient, the machine

may

fall

into

a

trouble because

of

lack

of

grease.

0,6

-

0,7

mm

An\

Grease

will

come out from here.

7

.?