MAINTENANCE

INSTRUCTIONS

-

Turn

off

the engine and remove the spark plug connector when replacing or sharpening cutting tools,

also

when cleaning the cutter

or

cutting

device

or

carrying out any maintenance.

-

Never straighten

or

weld

a

damaged cutting blade.

-

Inspect the cutting

blades

with the engine switched

off

at short, regular intervals

for

damage.

(Detection

of

hairline

cracks

by means of tapping-noise test.) Beware the teeth

are

sharp.

-

Clean the Hedge Trimmer at regular intervals and check that

all

screw and nuts

are

well tightened.

-

Never service

or

store the Hedge Trimmer in the vicinity

of

naked flames to avoid fires.

-

Always wear leather gloves when handling

or

sharpening

the

blades

as

they

are

sharp.

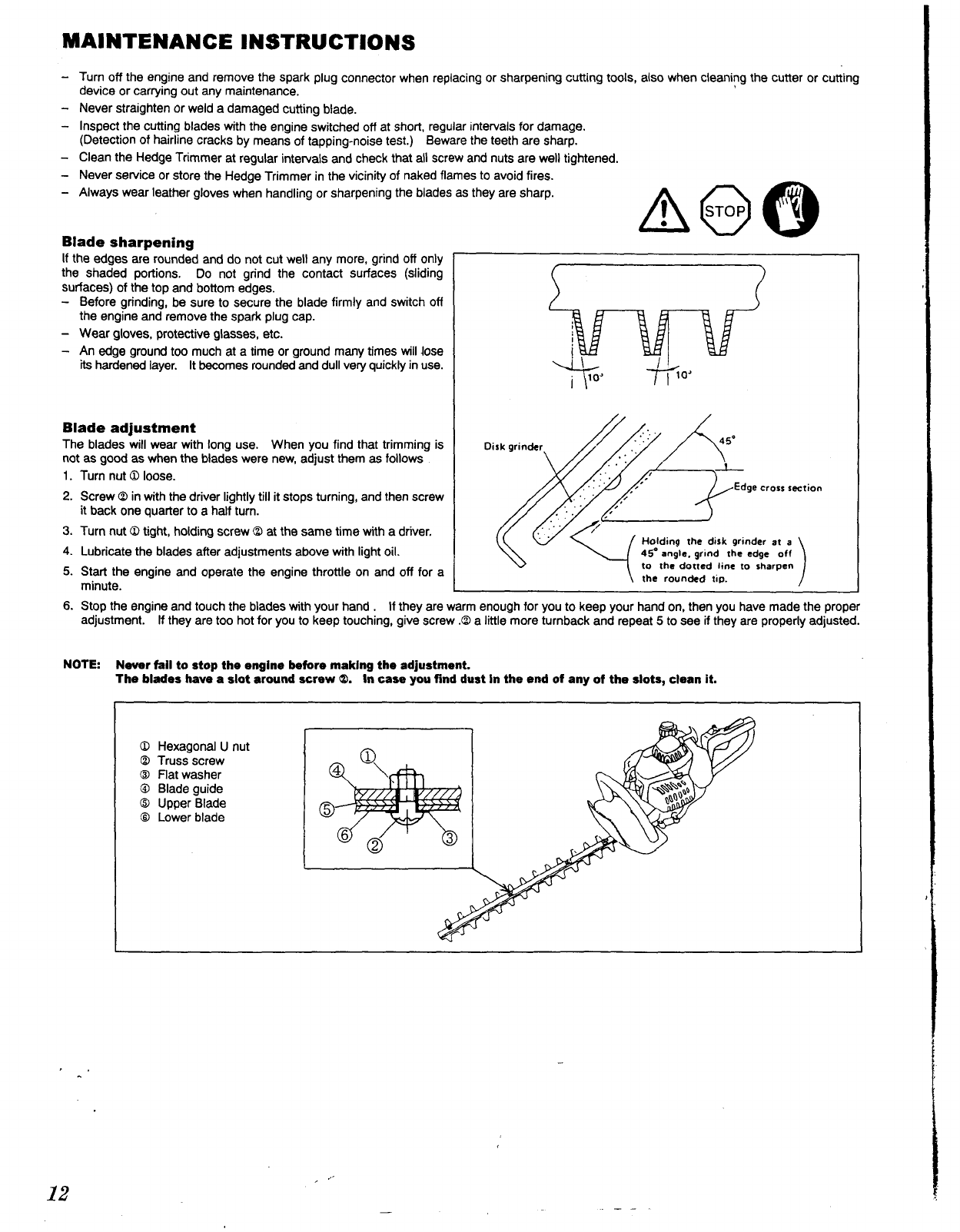

Blade sharpening

If

the edges

are

rounded and do not cut well any more, grind

off

only

the shaded portions.

Do

not grind the contact

surfaces

(sliding

surfaces)

of

the top and bottom edges.

-

Before grinding, be

sure

to secure the blade firmly and switch

off

the engine and remove the

spark

plug cap.

-

Wear gloves, protective glasses, etc.

-

An

edge

ground

too

much at

a

time

or

ground many times

will

lose

its

hardened layer. It becomes rounded and dull very quickly in

use.

Blade adjustment

The blades will wear with long

use.

When you find that trimming

is

not

as

good

as

when the blades were new, adjust them

as

follows

1.

Turn nut

Q

loose.

2.

Screw

Q

in with the driver lightly till it stops turning, and then screw

it

back

one quarter to

a

half turn.

3.

Turn nut

Q

tight, holding screw

Q

at the same time with

a

driver.

4.

Lubricate the

blades

after

adjustments above with light

oil.

5.

Start the engine and operate the engine throttle on and

off

for

a

minute.

Holding

:he

dirk grinder

at

a

45'

angle. grind :he edge

off

to

rho

dotted line

to

sharpen

the rounded

:ip.

6.

Stop the engine and touch the

blades

with your hand

.

If

they

are

warm enough for you to keep your hand on, then you have made the proper

adjustment.

If

they

are

too hot

for

you

to

keep touching, give screw

.Q

a

little more turnback and repeat

5

to

see

if

they

are

properly adjusted.

NOTE

Never

fail

to stop the engine before maklng the adjustment.

The blades have

a

slot

around

screw

Q.

In

case

you find dust In the end

of

any

of

the slots, clean it.

Q

Hexagonal

U

nut

Q

Trussscrew

0

Flat washer

8

Blade guide

0

Upper Blade

8

Lower

blade

12