27

Cleaning the brake band and sprocket interior

Replacing/cleaning the spark arrester screen

Replacing the saw chain

CAUTION:

Use only chains and guide bars designed for this saw

(see the Extract from the spare-parts list and page 18)!

B

C

1

2

A

6

7

2

4

3

1

5

STOP

CAUTION: Before doing any work on the guide bar or

chain, always switch off the engine and pull

the plug cap off the spark plug (see "Replacing

the spark plug"). Always wear protective gloves!

CAUTION: Start the chain saw only after having assem-

bled it completely and inspected!

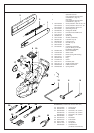

- Remove the sprocket guard (A/1) (See "PUTTING INTO

OPERATION" figs. A and B).

- Turn the chain tightener screw (A/2) to the left (counter-

clockwise) until you feel resistance.

- Remove the chain (A/3) and guide bar (A/4).

- Clean the interior with a brush, in particular the brake-band

area (A/5).

NOTE:

Make sure that no residue or contaminants remain in the oil

guide groove (A/6) and the chain tightener (A/7).

- For replacing the guide bar, chain, and sprocket see

"PUTTING INTO OPERATION".

NOTE:

The chain brake is a very important safety device and like

any other component subject to normal wear and tear.

Regular inspection and maintenance are important for

your own safety and must be done by a MAKITA service

center.

The felt filter (D/1) of the fuel filter can become clogged. It is

recommended to replace the fuel filter once every three months

in order to ensure unimpeded fuel flow to the carburetor.

To remove the fuel filter for replacement, pull it out through the

tank filler neck using a piece of wire bent at one end to

form a hook.

Replacing the fuel filter

Check the sprocket (B/1) before mounting a new chain.

The sprocket is located underneath the clutch drum (B/2).

CAUTION:

Worn out sprockets (C) may damage the new chain and must

therefore be replaced. If the wear marks on the teeth are very

pronounced (about 0,5 mm /0.02” deep), the sprocket should

be replaced.

Do not attempt to replace the sprocket yourself. Sprocket

replacement requires special training and tools and must be

done at a MAKITA service center.

E

2

1

The spark arrester screen should be checked and cleaned

regularly.

- Loosen the 3 screws (E/1) and remove the spark arrester

screen (E/2).

- Reassembly the spark arrester screen and tighten the

screws. The two long screws must be tigthed with a torque

of 6,3 ft. lb.(8,5 Nm).

CAUTION:

Do not use sharp or pointed objects for screen cleaning.

Damaged or misformed screen wires may result.

D

1