LUBRICATION

There are 4 pressure lubrication points on the mower.

All are zerk type grease fittings. Use a quality light

grease at these points. The bronze clutch collars each

have a grease fitting. These are located at the front of

the tractor on the left and right sides underneath the

main guard. Lubricate with 1 or 2 shots of grease every

10 hours of operation. The caster post has a fitting. It is

located just above the attachment point of the caster

wheel. Lubricate this every 20 hours of operation. The

last fitting is located on the differential, between the

rolls or tires depending on how your mower is

equipped. Lubricate this every 100 hours of operation.

Keep all chains well lubricated with a thin lubrication

oil. It is best to lubricate them after each mowing or

every 4 hours of use. This prevents rusting while stand-

ing idle and allows the oil to penetrate to the pin and

bearings by capillary action. When a chain is operated

without lubricant, the chain will wear prematurely and

the elongated chain will in turn wear the sprockets to

conform to the pitch of the chain.

Worn chains make expensive repairs because the

sprockets as well as the chains must be replaced.

Proper lubrication will give you many years of trouble-

free service.

CLEANING AND LUBRICATING AFTER

USE

When cutting is finished, clean the machine. It is much

easier to clean now than later. This is a good time to oil

the chains and lubricate the mower, allowing the oil to

penetrate and the grease to flush out grit. If a high

pressure wash down is used it is imperative to lubricate

thoroughly after cleaning.

Inspect the mower for any loose or worn components

and replace if necessary. If you do not understand the

mechanics of the mower, contact your dealer for ser-

vice.

ENGINE

The operating and maintenance instructions for the

Honda engine are explained in a manual furnished by

the engine manufacturer which is included in the infor-

mation packet you received with your mower.

BEARINGS

All parts that constantly rotate are carried on ball bear-

ings. The reel, clutch shaft, height roller and roller axle

have permanently sealed bearings. The reel chain

idlers and caster wheel are carried on semi-precision

bearings and may require lubrication. Pivot points such

CLUTCHES

The clutches are dry multi disc type, limited load,

enclosed and non adjustable, using molded friction

discs, hardened dogs and cone and bronze shift-

ing collar.

as reel link arms, reel bearing housings, etc. have

sintered bronze bushings.

TRACTOR ROLLS

The tractor rolls are in reality hard rubber tires. They

are mounted on a single axle which drives them

through differential gears. The differential is com-

posed of two steel bevel gears and two steel pinions

with hardened teeth, fully enclosed and packed in

grease.

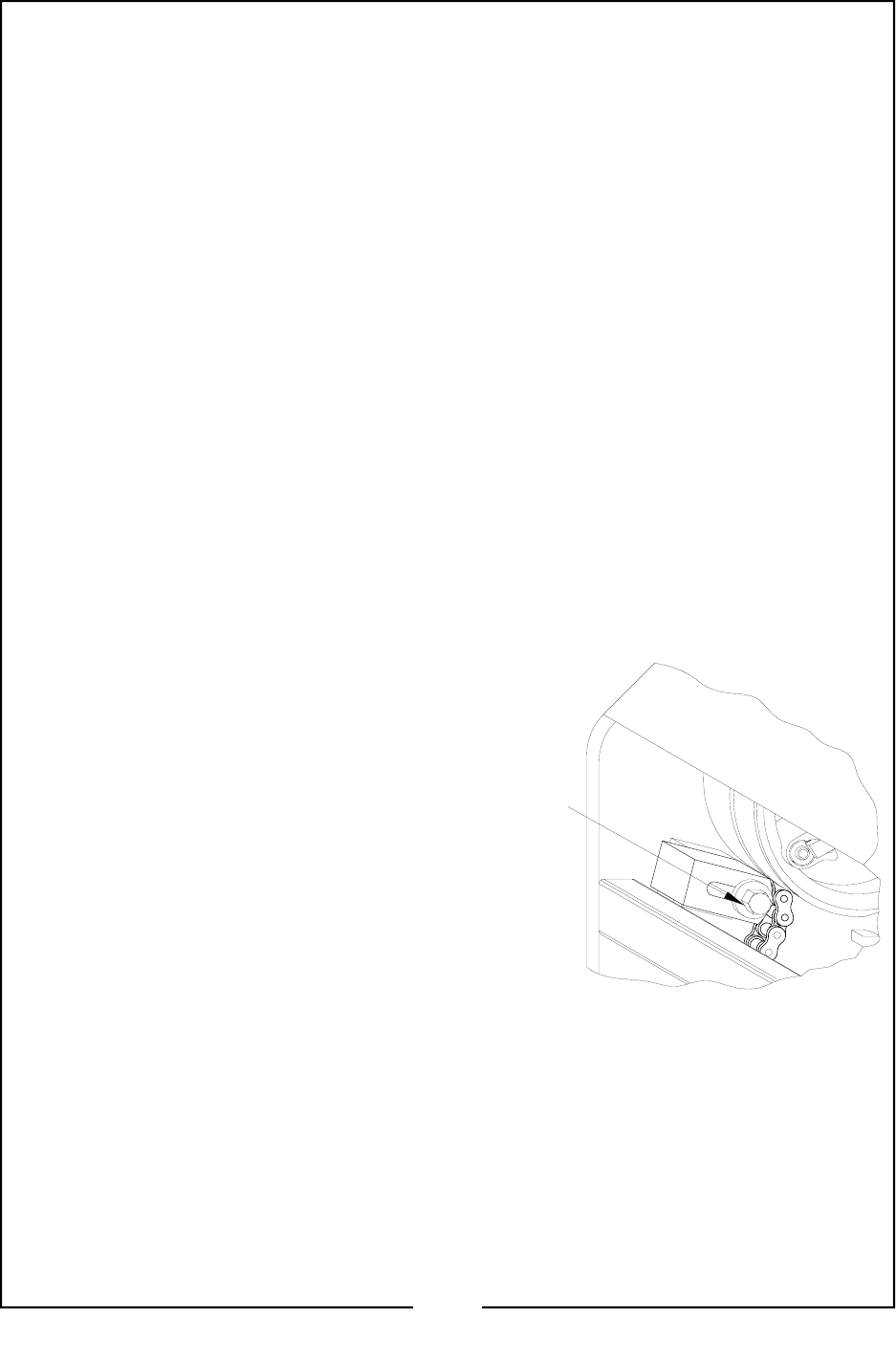

TRACTOR CHAIN TENSION ADJUST-

MENT

On occasion it is necessary that slack be taken up

on the tractor chain. Tension should be adjusted so

that there is a slight movement by hand pressure.

Excessive tension will result in loss of power and

premature wear on components. To adjust the trac-

tor chain, loosen the bolt on the chain adjuster and

push on the plastic block until the desired tension is

achieved. (See figure below) Tighten the bolt to se-

cure the tensioner block. When the chain has elon-

gated to the point of using all of the adjustment, it

will be necessary to take out a link of chain.

LOOSEN

BOLT

SECTION 4—MAINTENANCE

7