REEL BEDKNIFE

Whenever the bedknife is replaced it is essential that

the reel and blade be ground or lapped to alignment.

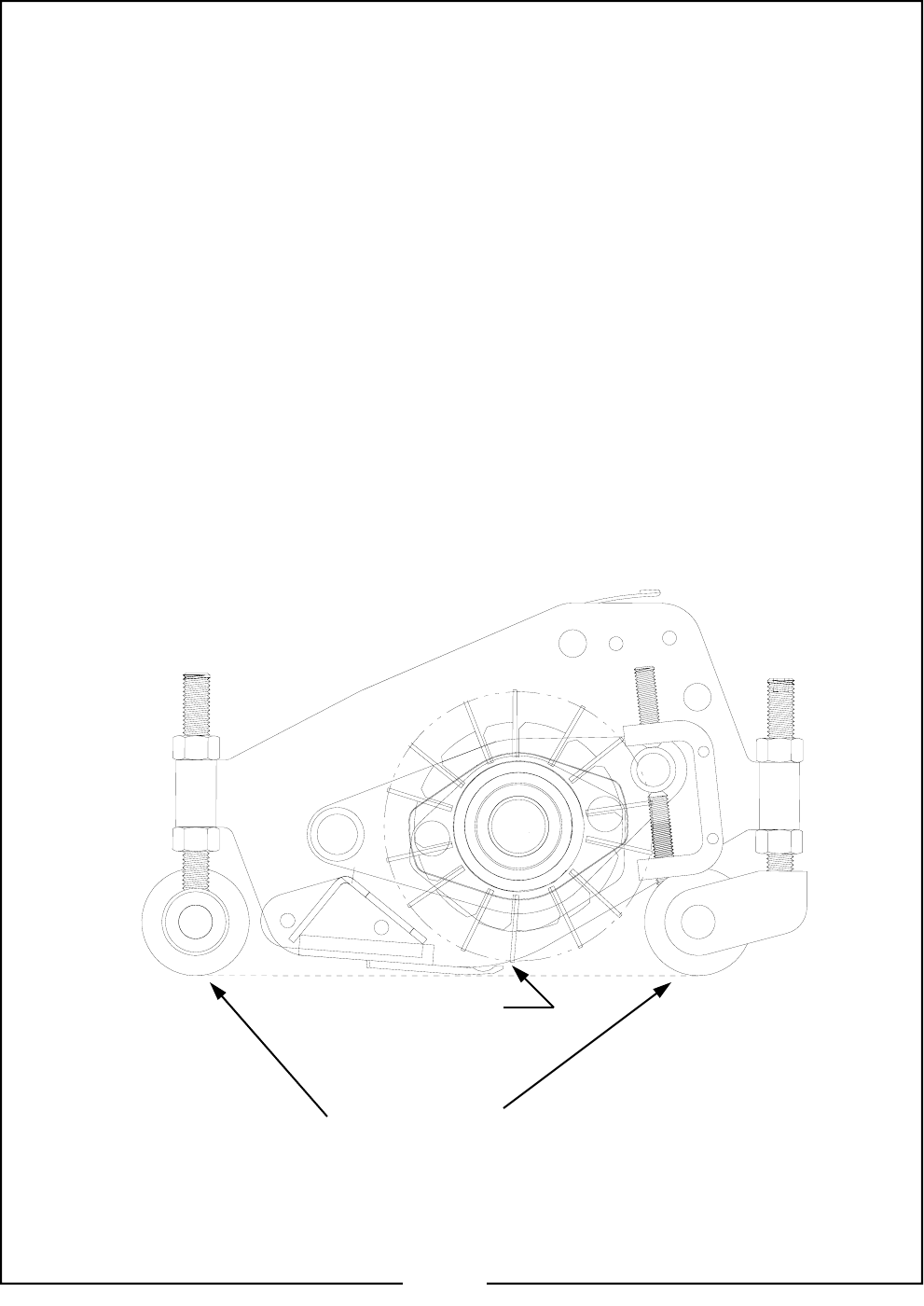

REEL TO BEDKNIFE ADJUSTMENT

The cutting reel is mounted on sealed ball bearings.

These bearings are carried in brackets hinged to the

reel side plates. The hinged brackets have springs

which urge the reel blades toward the stationary blade

(See figure below). An adjustable stop screw limits the

swing of these brackets and hence the approach of the

reel blades to the stationary blade. The correct setting

is when these blades just touch each other. Always

strive to maintain “light” reel to bedknife contact.

Note: If the blades rub together too heavily, the wear is

excessive and the power to drive them increases with

the pressure.

If the blades are too far apart, it is impossible to cut

grass. The tendency will be to munch the grass and

wedge it between the reel and bedknife.

MAINTAINING BLADE SHARPNESS

To provide consistent performance, lap the cutter blades

on a regular basis, ideally after every 40 to 60 hours of

operation. Your dealer will be able to assist you in main-

taining Locke’s legendary cut.

If you have the equipment to lap your reel, follow the steps

below.

1. Loosen the reel adjusting screws enough to cause a

slight friction on the bedknife.

2. Attach a lapping motor to the reel. A lapping motor is

a device that spins the reel in reverse at approxi-

mately 125 rpm. (Use Lapping Adapter P/N 5102).

3. Saturate a brush with lapping compound and apply it

to the reel. 200 grit is recommended.

4. Continue lapping until the reel runs without the Inter-

mittent grinding sounds caused by high spots.

5. Thoroughly clean all lapping compound from the cut-

ter unit.

6. Reset the adjusting screws so that the reel blades

just touch the bedknife. Each blade should cleanly cut

a piece of newspaper at all points across the bed-

knife.

REEL TO BEDKNIFE

CLEARANCE

HEIGHT ROLLERS

8