10

RTA10 & RTA15 Series Rotary Tillers 311-252M

5/05/06

Land Pride

Section 1 Assembly and Set-Up

Table of Contents

Driveline Installation

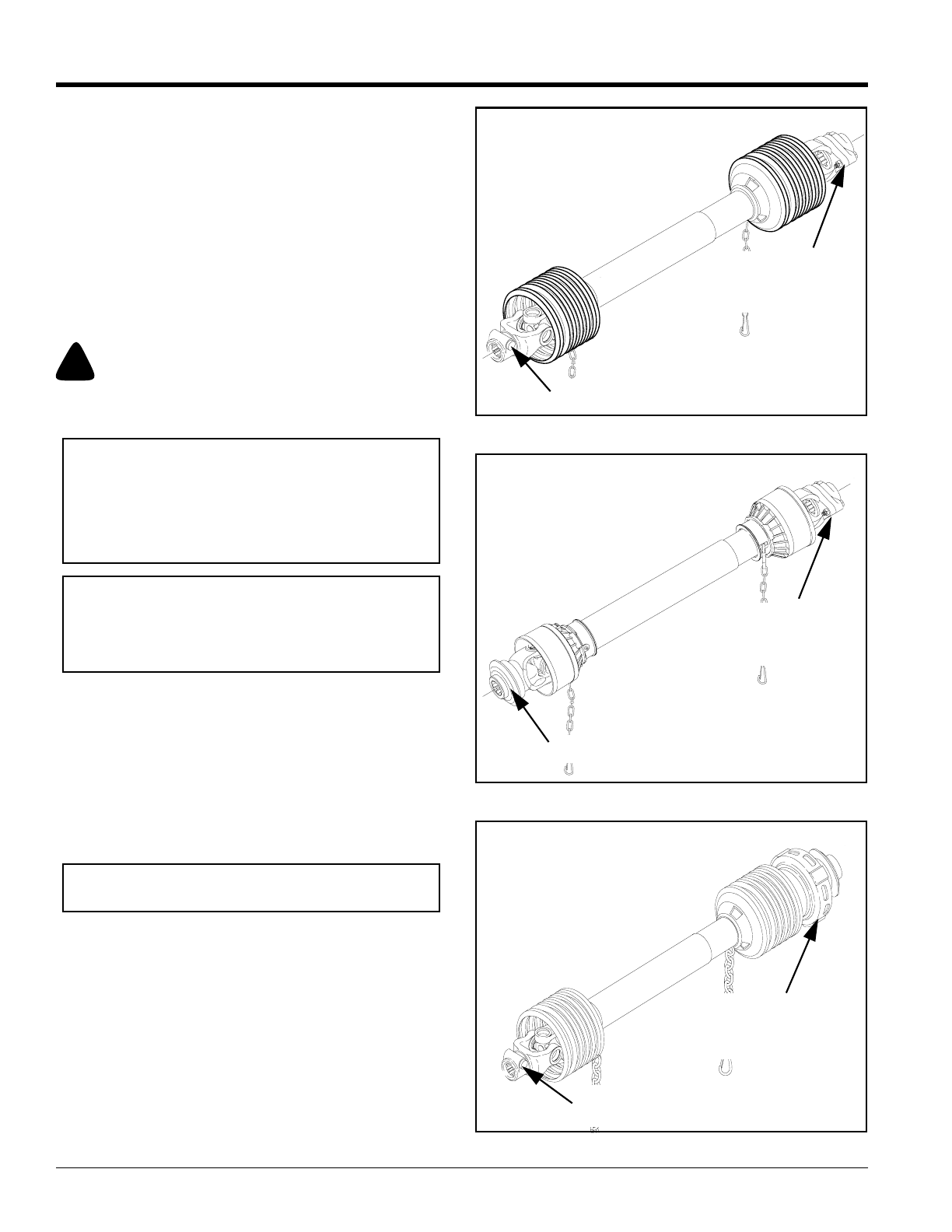

Refer to Figure 1-3, Figure 1-4 and Figure 1-5

The tiller driveline is coupled to the tractor and implement

shafts with either push pin couplers, pull collar couplers

or a combination of both and with either a shear bolt or

slip clutch on one end for protection from shock loads.

Always engage the PTO at low engine rpm to minimize

start-up torque on the driveline. Drivelines with friction

clutches must go through a “run-in” operation prior

to initial use and after long periods of inactivity. See

“Section 4 Maintenance and Lubrication” on page 17 for

a detailed description of maintaining the driveline.

!

CAUTION

Tractor PTO shield and all tiller guards must be in place at all

times during operation!

Checking Driveline Minimum Length

Refer to Figure 1-1 on page 8:

1. Start tractor and slowly engage tractor’s hydraulic

3-point to lift the lower arms until the Rotary Tiller’s

driveline shaft is approximately level with tractor's

PTO shaft.

2. Slide the slip clutch or shear bolt yoke end of driveline

(#12) over the splined input shaft of gearbox (#1).

Secure with driveline yoke locking device.

3. Slide the opposite driveline yoke end over the tractor’s

splined driveline shaft. Secure with driveline yoke

locking device. Skip to step 4 if driveline fits between

tractor and implement.

Refer to Figure 1-6 on page 11:

4. The driveline will require shortening if it is too long to

fit between the tractor and tiller gearbox. Shorten

driveline as follows:

a. Raise 3-point lower arms until tiller and tractor

PTO shafts are approximately level with each

other. Securely block Rotary Tiller frame in this

position. Set tractor in park, shut tractor engine

off, set park brake and remove switch key.

IMPORTANT: Always check driveline maximum and

minimum length during initial setup, when connecting

to a different tractor and when alternating between

using a quick hitch and a standard 3-point hitch. More

than one driveline may be required to fit all

applications.

IMPORTANT: Itis necessary to aligning the tractor’s

PTO shaft level with tiller’s PTO shaft when checking

to see if the driveline’s minimum length is correct.

Too long a driveline can damage the tractor, gearbox

and driveline.

IMPORTANT: For easier access to gearbox input

shaft, remove driveline guard (#10).

Figure 1-3

Figure 1-4

Figure 1-5

Implement End

Tractor End

Push Pin Coupling

Push Pin Coupling

With

Shear Bolt Protection

22232

Implement End

Tractor End

Pull Collar Coupling

Push Pin Coupling

With

Shear Bolt Protection

22233

Implement End

Tractor End

Push Pin

Coupling

Pull Collar Coupling

With

Slip Clutch Protec-

22234