34

Section 4: Maintenance & Lubrication

OS1548 and OS1572 Overseeder (S/N 166724+) 308-303M

2-16/09

Land Pride

Table of Contents

Driveline Slip Clutches

!

CAUTION

Engage parking brake, disengage PTO, shut off tractor, and

remove key before working on or around the driveline and/or

slip clutch.

!

CAUTION

Slip clutches that have been in use or have been slipped for only

two or three seconds during run-in may be too hot to touch.

Allow a hot clutch to cool before working on it.

Drive components are protected from shock loads with a

friction slip clutch. The clutch must be capable of

slippage during operation to protect the gearbox,

driveline and other drive train parts.

Friction clutches should be “run-in” prior to initial

operation and after long periods of inactivity to remove

any oxidation that may have accumulated on the friction

surfaces. Repeat “run-in” instructions at the beginning of

each season and when moisture and/or condensation

seizes the inner friction plates.

Refer to Figure 4-8 to determine which friction clutch

your seeder has. Follow “run-in” instructions on the

following pages for your specific clutch type.

Clutch Types

Figure 4-8

Type A Clutch Type B Clutch

26619

Type A Clutches

Clutch Run-In

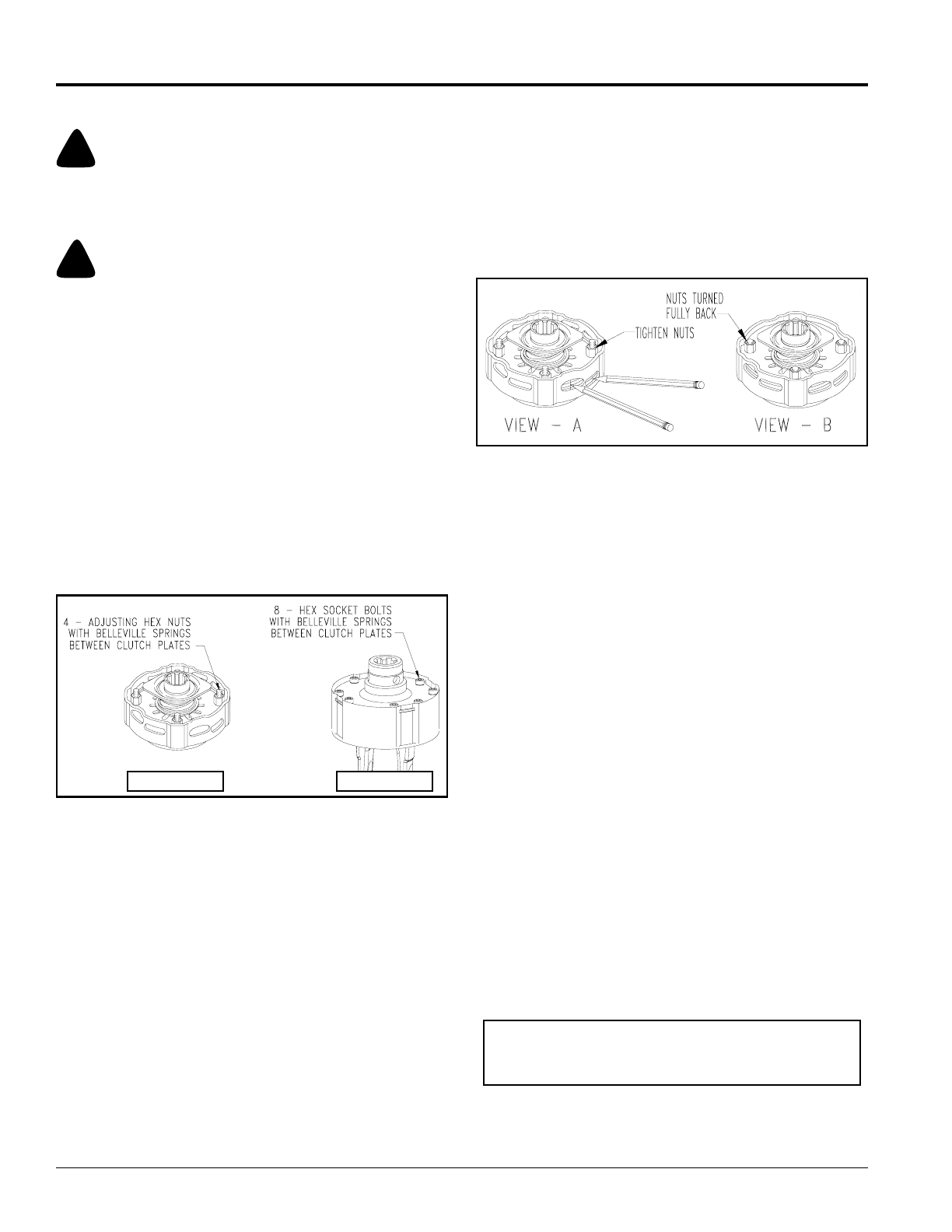

Refer to Figure 4-9 (View - A):

1. Using a pencil or other marker, scribe a line across the

exposed edges of the clutch plates and friction disks.

2. Tighten all 4 nuts uniformly until spring load is low

enough that the clutch slips freely with PTO

engaged.

Type C Clutch Run-In

Figure 4-9

3. Make sure the area is clear of all bystanders and

machine is safe to operate.

4. Start tractor and engage PTO for 2-3 seconds to

permit slippage of clutch surfaces. Disengage PTO,

then re-engage a second time for 2-3 seconds.

Disengage PTO, shut off tractor and remove key.

Wait for all components to stop before dismounting

from tractor.

5. Inspect clutch and ensure that the scribed markings

made on the clutch plates have changed position.

Slippage has not occurred if any two marks on the

friction disk and plate are still aligned. A clutch that

has not slipped must be disassembled to separate

the friction disk plates. See “Clutch Disassembly,

Inspection & Assembly” below.

Refer to Figure 4-9 (View - B):

6. If no two marks on the friction disk and plate are still

aligned, Turn all 4 nuts fully back.

7. Allow clutch to cool to ambient temperature before

operating again. Clutch is now ready for use.

8. The clutch should be checked during the first hour of

cutting and periodically each week. An additional set

of scribe marks can be added to check for slippage.

Clutch Disassembly, Inspection & Assembly

If clutch run-in procedure above indicates that one or more

of the friction disks did not slip, then the clutch must be

disassembled into separate friction disks.

23696

IMPORTANT: Before proceeding, secure clutch

firmly in a vise or other clamping device to prevent

injury.