31

Section 4: Maintenance & Lubrication

2-16/09

OS1548 and OS1572 Overseeder (S/N 166724+) 308-303M

Land Pride

Table of Contents

Section 4: Maintenance & Lubrication

Maintenance

Proper servicing and adjustment is the key to the long life

of any implement. With careful inspection and routine

maintenance, you can avoid costly down time and repair.

1. After using your Overseeder for several hours, check

all bolts to be sure they are tight.

2. Lubricate areas noted in the “Lubrication” section.

3. Adjust idlers to remove excess slack from chains.

Clean and use chain lube on all roller chains as

needed.

4. Feed cup drive sprocketshould be oiledin its squarebore.

Move feedcup adjustment lever away fromsprocketas far

as possible in order to get oil back into square.

5. Always maintain proper air pressure in turf tires.

6. Replace any worn, damaged or illegible safety labels by

obtaining new labels from your Land Pride Dealer.

Storage

Clean, inspect, service and make necessary repairs to

the seeder when parking it for long periods and when

parking it at the end of a working season. This will help

ensure the seeder is ready for field use the next time you

hook-up to it.

1. Completely clean the seed box of seed and other

debri before storing.

2. Lubricate and adjust all roller chains and fittings.

3. Feed cup drive sprocket hub should be oiled in its

square bore. Squirt oil on to the square feed cup

shaft and move feed cup adjustment lever back and

forth in order to get the oil back into the square bore.

This is most important before putting the Overseeder

in storage.

4. Store the Overseeder and its attachments inside if

possible to extend the Overseeder’s life.

5. When in storage, lower the Overseeder with rollers

on a board or hard surface and adjust the parking

stand to properly support the seeder.

6. Repaint parts where paint is worn or scratched to

prevent rust.

7. Replace all damaged or missing decals.

8. Check knives for wear and replace if necessary.

9. Inspect Overseeder for loose, damaged or worn

parts and adjust or replace as needed.

10. Drain gear case and chaincase oil. Drain oil in gear

case by removing plug from the bottom side of the

rotor housing. Drain oil in chaincase by removing oil

level plug and fill plug.

Individual Knife Replacement

The following instructions are for replacing only a few

bent and/or broken knives on the rotor without removing

the rotor from the Overseeder frame. It is best to remove

the rotor from the frame if replacing all knives. See “Rotor

Maintenance” on this page to replace all knives.

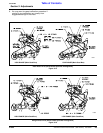

Refer to Figure 4-1:

1. Remove two cap screws (#2) and locknuts (#3) from

knife (#1) to be replaced.

2. Remove damaged knife and install new knife (#1) on

same side of attaching flange as the damaged knife

was using new 7/16” lock nuts (#3), Land Pride Part

No. 803-108C. Torque nuts to 68 ft-lbs.

Individual Knife Replacement

Figure 4-1

Rotor Maintenance

It is best to remove the rotor knife assembly when

replacing the complete set of knives, right hand bearing

and/or bearing seal. Knives are worn out when they can

not be set to penetrate the soil to your desired depth.

!

WARNING

Before making adjustments on the Overseeder, shut off the

tractor, disengage PTO, wait for all moving parts to stop and

lock brakes before dismounting tractor. Securely block

Overseeder on safe supporting stands and disconnect tractor.

1. Attach chain, cable or lifting strap to the two

Overseeder slingbrackets. Use an overhead hoist for

rotor removal and installation.

2. Remove chain guard from right hand side of your

Overseeder.

3. Remove drive chain as follows:

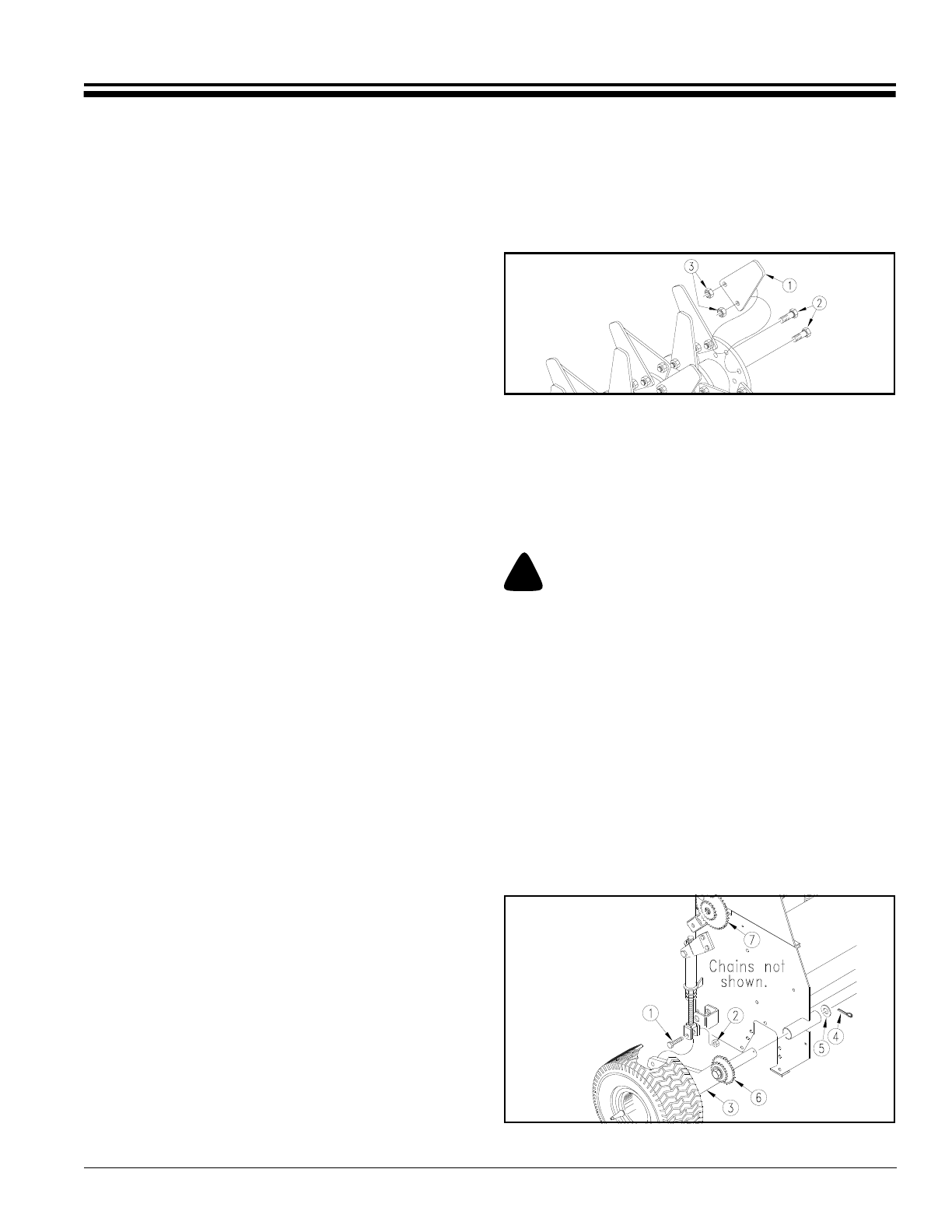

Overseeders With Gauge Wheel Drive

Refer to Figure 4-2:

a. Remove chain from gauge wheel sprocket (#6) to

seed cup sprocket (#7).

b. Remove 5/8” x 2 1/2” long bolt (#1) and nut (#2).

Gauge Wheel Disconnect

Figure 4-2

26768

14702