2

Table 1. Recommended Tilt Angles for Stand Alone

Fixed Systems - Based on Winter Performance

For grid tie installations where the solar modules are attached to a

permanent structure, PV modules should be tilted at an angle equal to

the site's latitude. This will typically result in the highest annual energy

output.

7. INSTALLING KD SERIES MODULES

The minimum spacing of 50mm (2”) is required between PV module

and the mounting surface around the perimeter of PV module. The

frame of each PV module has 9mm (0.35”) diameter mounting holes

(Refer to Module Mounting Specifications). These are used for fixing

PV modules to the supporting structure. PV module frames must be

attached to a support structure using M8 (5/16”) stainless steel screw in

a minimum of four (4) places symmetrical on PV module. The stainless

steel screw used for fixing the module frame should secure with an

adequate torque. (usually, 19 N-m (14 ft-lb).) An example of a ground

mounted structure is shown in Figure 2. The four holes close to the

corners of the module are most often used for installation. Refer to the

Mounting Specifications for the position of these holes. Clearance

between PV module frame and the mounting surface may be required

to prevent the junction box from touching the surface, and to circulate

cooling air around the back of PV module. Spacing between PV

modules must be a minimum of 1/8" (3.2 mm) to allow for thermal

expansion. If the modules are to be installed on the roof or wall of a

building, the stand-off method or the rack method is recommended.

STAND-OFF METHOD: PV modules are supported parallel to the

surface of the building wall or roof. Clearance between PV module

frames and surface of the wall or roof is required to prevent PV module

and / or wiring from damage.

The recommended stand-off height is 4.5” (about 115 mm). If other

mounting means are employed, this may affect the Listing For Fire

Class Ratings.

RACK METHOD: The supporting frame is used to mount PV modules

at correct tilt angles. PV modules specified in this installation manual

are not designed for Building Integrated Photovoltaic (B.I.P.V)

application as part of a roof or wall. The mounting design may have an

impact on the fire resistance.

OTHER: Other method(s) certified by a registered professional

engineer, and in compliance with local codes.

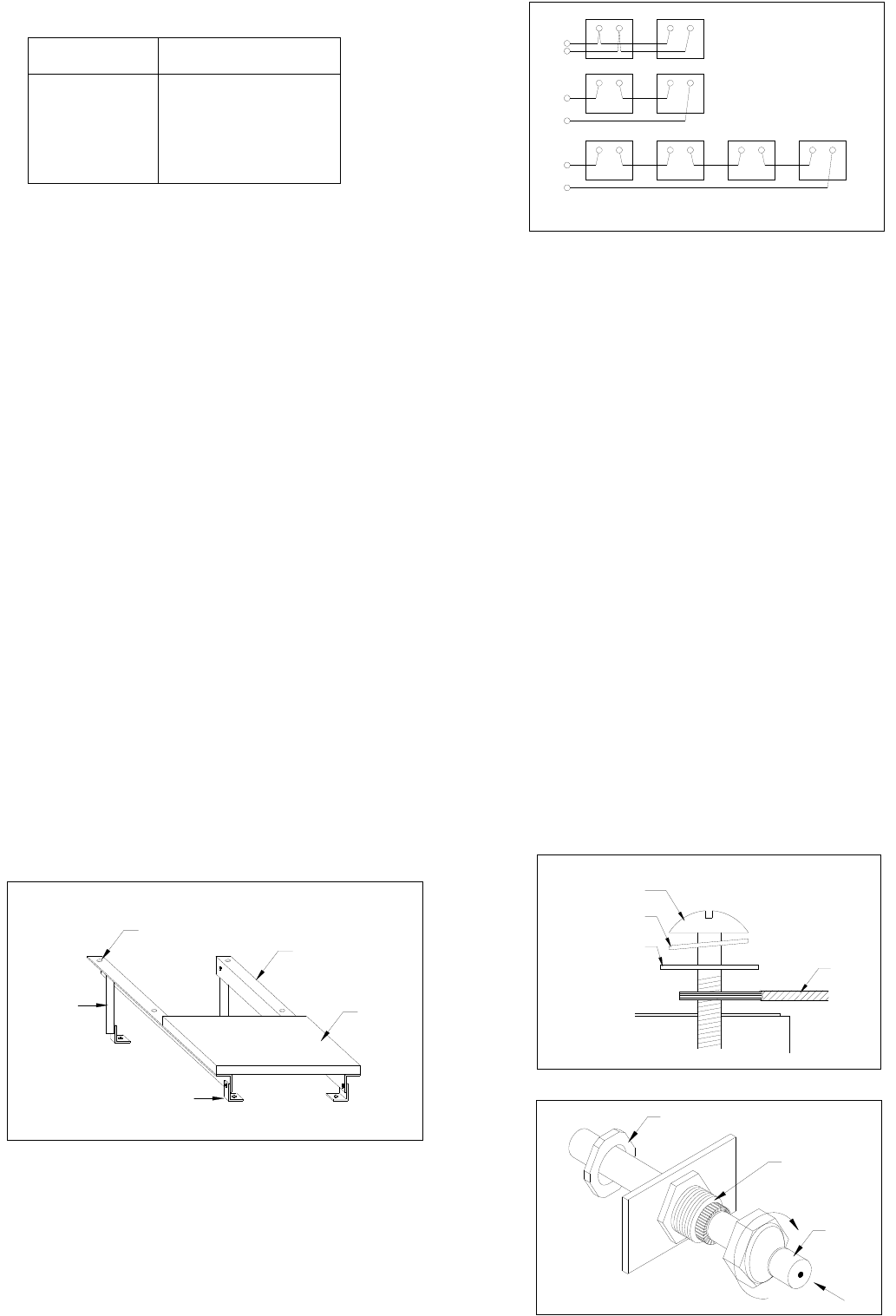

MOUNTING HOLE

ARRAY FRAME

MODULE

FOOT ANGLE

SUPPORT

LEGS

Figure 2. Basic Rack or Stand-off Mounting Structure

8. MODULE WIRING

As shown in Figure 3 Standard Wiring Examples, Kyocera PV modules

utilize the Type "IM" junction box (see J-box details). This junction box,

located on the back side of the module, is weatherproof and is

designed to be used with standard wiring or conduit connections.

A cable clamp with a minimum rating of IP65 must be used to maintain

the weatherproof integrity of the junction box. Bypass diodes are

preinstalled at factory.

EXAMPLE OF 'IM' TYPE J-BOX WIRING

+

-

24 VOLT (2 SERIES)

+

-

+

+- - + +- -

+

-

12 VOLT (2 PARALLEL)

- ++-

RED

BLACK

21

+--+

1 2

12

BLACK

RED

1

2

RED

12 212121

BLACK BLACK BLACK

48 VOLT (4 SERIES)

Figure 3. Standard Wiring Examples

To wire Kyocera PV modules:

A. Determine the nominal system array voltage of your system.

Each panel is equivalent to a 12 VDC nominal block. Standard

array voltages 12, 24 and 48 volt are shown as examples in

Figure 3.

B. Open the "IM" box cover by loosening the screws in the cover.

C. The wire used to interconnect PV modules may be single or two

conductors, from 14AWG (2.08 mm

2

) up to 10AWG (5.26 mm

2

)

gauge stranded copper wire, in a “SUNLIGHT RESISTANT” and

insulated for 90℃ minimum jacket cable. This cable is suitable for

applications where wiring is exposed to the direct rays of the sun.

The maximum and minimum outer diameters of the cable that may

be used with the cable connector are 8 mm and 6 mm respectively

(Figure 4).

D. Using a flat blade screw driver, remove only the appropriate

"KNOCK-OUTS" from the sides of the "IM" box.

E. Route wires through the knock-outs and clamps refer to

installation example (see Figure 5).

F. Gently hand tighten the terminal screws with cross slot (Phillips

-head) screwdriver. Do not over tighten, as the terminal can be

damaged.

(Recommendation Torque : 1.5N-m (13.3 in-lb)

G. The output wiring from the final module is generally run to a

separate array junction box. In commercial system, this wiring

from the array box to the next component (i.e. fuse box. or charge

regulator, etc.) is generally run in conduit. The maximum electrical

rating of an acceptable series fuse is 15 amperes.

H. After checking that PV module wiring is correct, close all the

junction boxes. Use a Phillips head screw driver to secure all

screws on the junction box cover to ensure a waterproof seal.

I. Refer to the cable clamp specifications for KD135SX-UPU and

KD140SX-UPU.

Refer to below for a cable clamp of our designation.

(Manufacturer / Part Number)

Cable Gland : LAPP / S2212 (NPT-1/2")

Nut : LAPP / 911371K (NPT-1/2")

TERMINAL SCREW

SPRING WASHER

CABLE

SQUARE WASHER

Figure 4. Ring or Spade Terminal Connectors

CABLE

NUT

CABLE CLAMP

SITE LATITUDE

IN DEGREES

FIXED TILT ANGLE

0°TO 15

15°TO 25°

25°TO 30°

30°TO 35°

35°TO 40°

40°+

15°

SAME AS LATITUDE

LATITUDE + 5°

LATITUDE + 10°

LATITUDE + 15°

LATITUDE + 20°