TPTPS-6331 5/04IV Safety Precautions and Instructions

Welding on the generator set. Can

cause severe electrical equipment

damage. Before welding on the

generator set perform the following

steps: (1) Remove the battery cables,

negative (--) lead first. (2) Disconnect

all engine electronic control module

(ECM) connectors. (3) Disconnect all

generator set controller and voltage

regulator circuit board connectors.

(4) Disconnect the engine battery-

charging alternator connections.

(5) Attach the weld ground connection

close to the weld location.

Installing the battery charger.

Hazardous voltage can cause

severe injury or death. An

ungrounded battery charger may

cause electrical shock. Connect the

battery chargerenclosure totheground

of a permanent wiring system. As an

alternative, install an equipment

grounding conductor with circuit

conductors and connect it to the

equipment grounding terminal or the

lead on the battery charger. Install the

battery charger as prescribed in the

equipment manual. Install the battery

charger in compliance with local codes

and ordinances.

Connecting the battery and the

battery charger. Hazardous voltage

can cause severe injury or death.

Reconnect the battery correctly,

positive to positive and negative to

negative, to avoid electrical shock and

damage to the battery charger and

battery(ies). Have a qualified

electrician install the battery(ies).

Short circuits. Hazardous

voltage/current can cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove all jewelrybefore servicing the

equipment.

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death. Install

a transfer switch in standby power

installations to prevent the connection

of standby and other sources of power.

Electrical backfeed into a utility

electrical system can cause severe

injury or death to utility personnel

working on power lines.

Heavy Equipment

Unbalanced weight.

Improper lifting can cause severe

injury or death and equipment

damage.

Do not use lifting eyes.

Lift the generator setusing lifting bars

inserted through the lifting holes on

the skid.

WARNING

Hot Parts

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

WARNING

Servicing the generator. Hot parts

can cause severe injury or death.

Avoid touching the generator set field

or exciter armature. When shorted, the

generator setfield and exciterarmature

become hot enough to cause severe

burns.

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

Servicing the engine heater. Hot

parts can cause minor personal

injury or property damage. Install the

heater before connecting it to power.

Operating theheater before installation

can cause burns and component

damage. Disconnect power to the

heater and allow it to cool before

servicing the heater or nearby parts.

Moving Parts

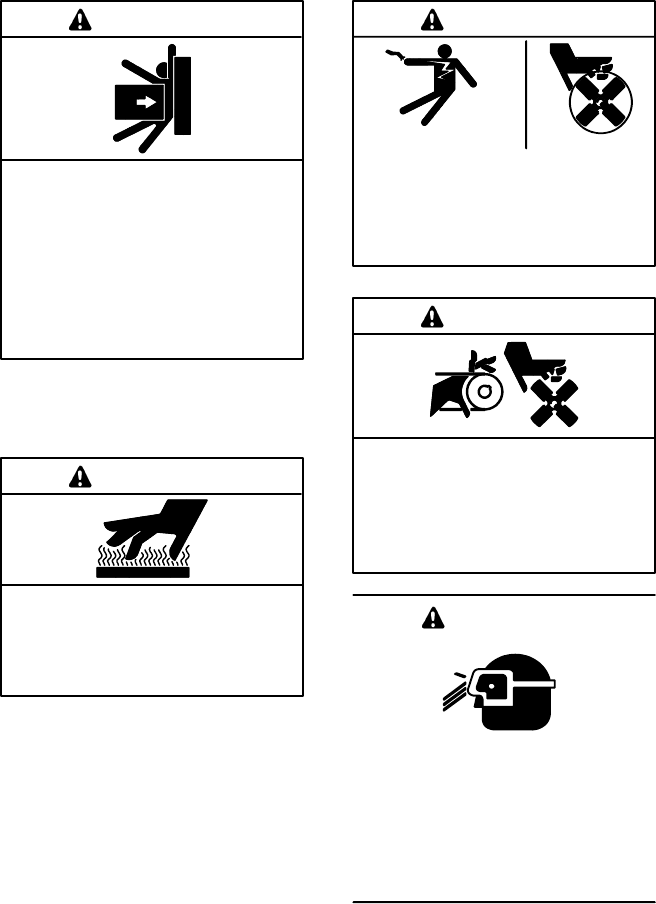

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Moving rotor.

WARNING

Rotating parts.

Can cause severe injury or death.

Operate the generator set only when

all guards, screens, and covers are in

place.

WARNING

Airborne particles.

Can cause severe injury or

blindness.

Wear protective goggles andclothing

when using power tools, hand tools,

or compressed air.

WARNING

Tightening the hardware. Flying

projectiles can cause severe injury

or death. Loose hardware can cause

the hardware or pulley to release from

the generatorset engineand cancause

personal injury. Retorque all

crankshaft and rotor hardware after

servicing. Do not loosenthe crankshaft

hardware orrotor thrubolt when making

adjustments or servicing the generator

set. Rotate the crankshaft manually in

a clockwise direction only. Turning the

crankshaft bolt or rotor thrubolt

counterclockwise can loosen the

hardware.