14 – English

ASSEMBLY

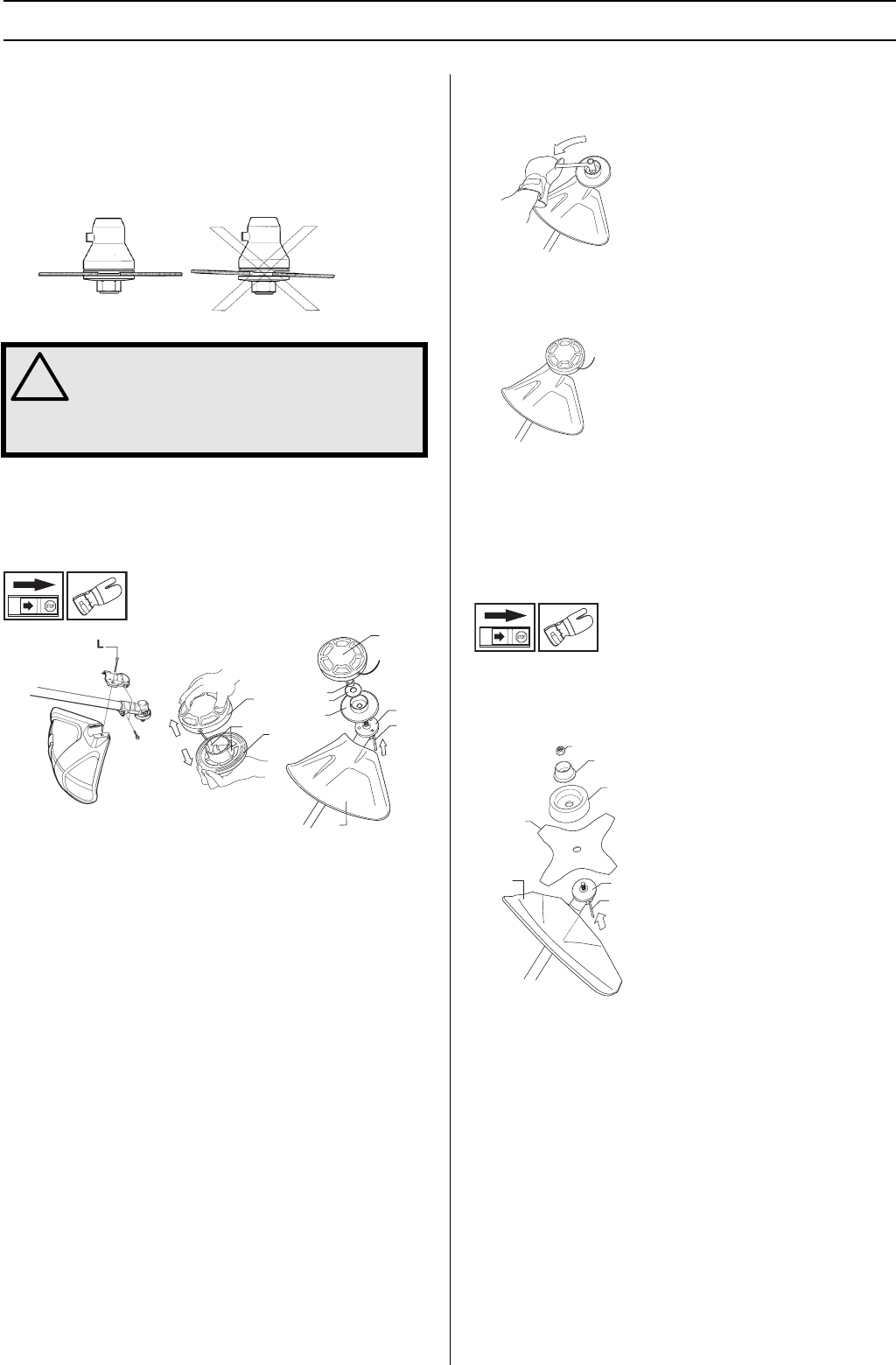

Fitting blades and trimmer heads

When fitting the cutting attachment it is extremely important

that the raised section on the drive disc/support flange

engages correctly in the centre hole of the cutting attachment.

If the cutting attachment is fitted incorrectly it can result in

serious and/or fatal personal injury.

Fitting the trimmer guard and Auto

32 trimmer head

(GC 2125)

• Fit the correct trimmer guard (A) for use with the trimmer

head. Hook the guard onto the fitting on the shaft and

secure it with the bolt (L).

• Fit the drive disc (B) on the output shaft.

• Turn the blade shaft until one of the holes in the drive disc

aligns with the corresponding hole in the gear housing.

• Insert the locking pin (C) in the hole to lock the shaft.

• To fit the trimmer head, first separate the two halves (see

diagram). Proceed as follows:

• Insert a finger into the centre hole of the cover (I) while

grasping the cover with your other fingers. Using the index

finger and thumb of your other hand, release the two

catches (J) that engage in the cut-outs in the bottom half

(K). Pull apart the trimmer head, grasping the cover firmly.

• Place the cover (I) and the support flange (F) on the

output shaft.

• Fit the nut (G). The nut must be tightened to a torque of

35-50 Nm (3.5-5 kpm). Use the socket spanner in the tool

kit. Hold the shaft of the spanner as close to the blade

guard as possible. To tighten the nut, turn the spanner in

the opposite direction to the direction of rotation (left-hand

thread).

• Fit the bottom half of the trimmer head (K) to the cover (I)

by pressing them together, with the cut-outs on the bottom

half aligned with the catches on the cover.

• To dismantle, follow the instructions in the reverse order.

Fitting the blade guard/combination

guard, grass blade and grass cutter

(GC 2125)

• Hook the blade guard/combination guard (A) onto the

fitting on the shaft and secure with the bolt. CAUTION!

Use the recommended blade guard. See the Technical

data section.

• Fit the drive disc (B) on the output shaft.

• Turn the blade shaft until one of the holes in the drive disc

aligns with the corresponding hole in the gear housing.

• Insert the locking pin (C) in the hole to lock the shaft.

• Place the blade (D), support cup (E) and support flange

(F) on the output shaft.

• Fit the nut (G). The nut must be tightened to a torque of

35-50 Nm (3.5-5 kpm). Use the socket spanner in the tool

kit. Hold the shaft of the spanner as close to the blade

!

WARNING! Never use a cutting attachment

without an approved guard. See the chapter

on Technical data. If an incorrect or faulty

guard is fitted this can cause serious

personal injury.

G

F

I

A

B

C

K

J

I

K

G

F

D

B

C

A

E