Replacing tines

CAUTION: To prevent injury: Wear heavy gloves when replacing tines.

To get the best performance from your tiller:

• Replace badly bent, worn, or broken tines immediatly.

• Replace worn or broken hardware (see your Frontier dealer for correct hardware).

• MAKE SURE to replace tines on ONE spindle at time to keep spiral tine pattern.

• Tine cutting edge MUST BE facing forward in direction of tine rotation.

SERVICE

Service - Page 24

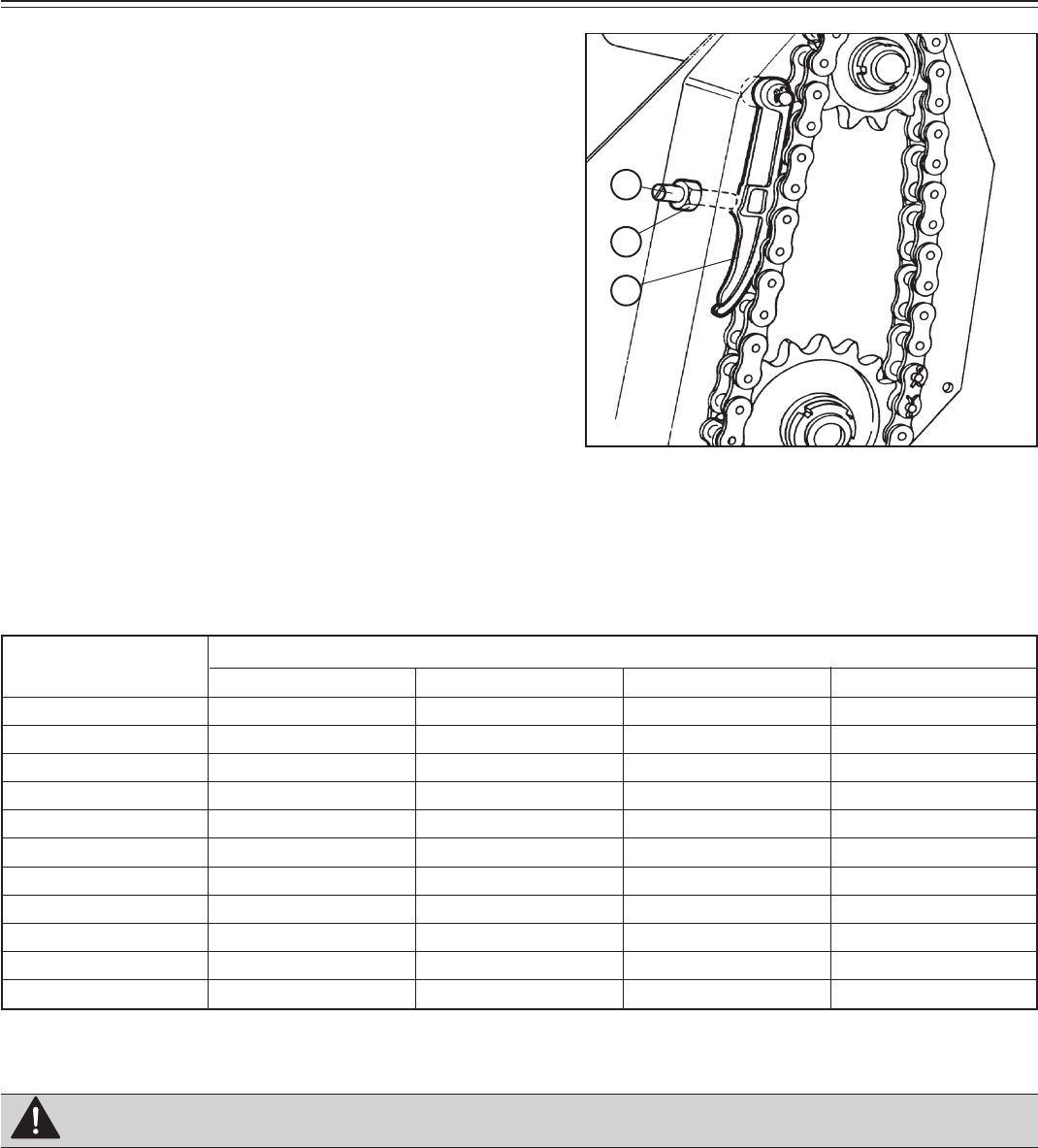

B

C

A

Chain stretcher

RT 1142-1149 and RT 1157-1165 model

Automatic chain stretcher regulates the tension of the

drive chain.

RT 1265 model

A special mechanical chain stretcher regulates the ten-

sion of the drive chain (A). If there is too much play, then

you must loosen lock nut (B) and tighten screw (C) as

much as necessary.

Then tighten lock nut which locks the adjustment screw

into place.

Service intervals

Every 50 working hours:

• Tighten mast brackets bolts.

• Tighten skid shoe bolts.

Fine pitch screws

CLASS

6.6 8.8 10.9 12.9

M8 x 1 15 (11) 26 (19) 36 (26.5) 44 (32.5)

M10 x 1.25 30 (22) 52 (38) 74 (54) 88 (65)

M12 x 1.25 51 (37.5) 91 (67) 127 (94) 153 (113)

M14 x 1.5 81 (60) 143 (105) 201 (148) 241 (178)

M16 x 1.5 120 (88) 214 (158) 301 (222) 361 (266)

M18 x 1.5 173 (127) 308 (227) 433 (319) 520 (384)

M20 x 1.5 242 (178) 431 (318) 606 (447) 727 (536)

M22 x 1.5 321 (237) 571 (421) 803 (592) 964 (711)

M24 x 2 411 (303) 731 (539) 1028 (758) 1234 (910)

M27 x 2 601 (443) 1070 (790) 1504 (1110) 1806 (1333)

M30 x 2 832 (614) 1480 (1090) 2081 (1535) 2498 (1843

)

Bolts tightening torques - settings given in Nm (lb-ft)