SERVICE

22 Service

• Practice Safe Service Procedures

CAUTION: To help prevent personal injury

caused by unexpected movement, be sure to

service machine on a level surface.

Before servicing or adjusting machine connected to a tractor:

1. Lower machine to the ground.

2. Engage tractor parking brake and/or place

transmission in “Park”.

3. Disengage PTO.

4. Shut off tractor engine and remove key.

5. Wait until all moving parts have stopped.

6. Disconnect PTO driveline from tractor.

The blades and blade pan may rotate for several minutes

after PTO is shut off. Look and listen for rotating

driveline to stop before working on the cutter.

When servicing blades or blade pan, it will be

necessary to work underneath cutter. Be sure to

support cutter frame at all four corner locations with

safety shop stands to prevent accidental lowering.

Do not position safety stands under wheel support

because these components can rotate.

• Disassembling and Assembling Driveline Shields

1. Separate telescoping parts.

2. Remove driveline shield screw (B).

3. Rotate cone to align tab (C) with hole (A)

and slide shield rearward off of driveline.

4. Assemble in reverse order.

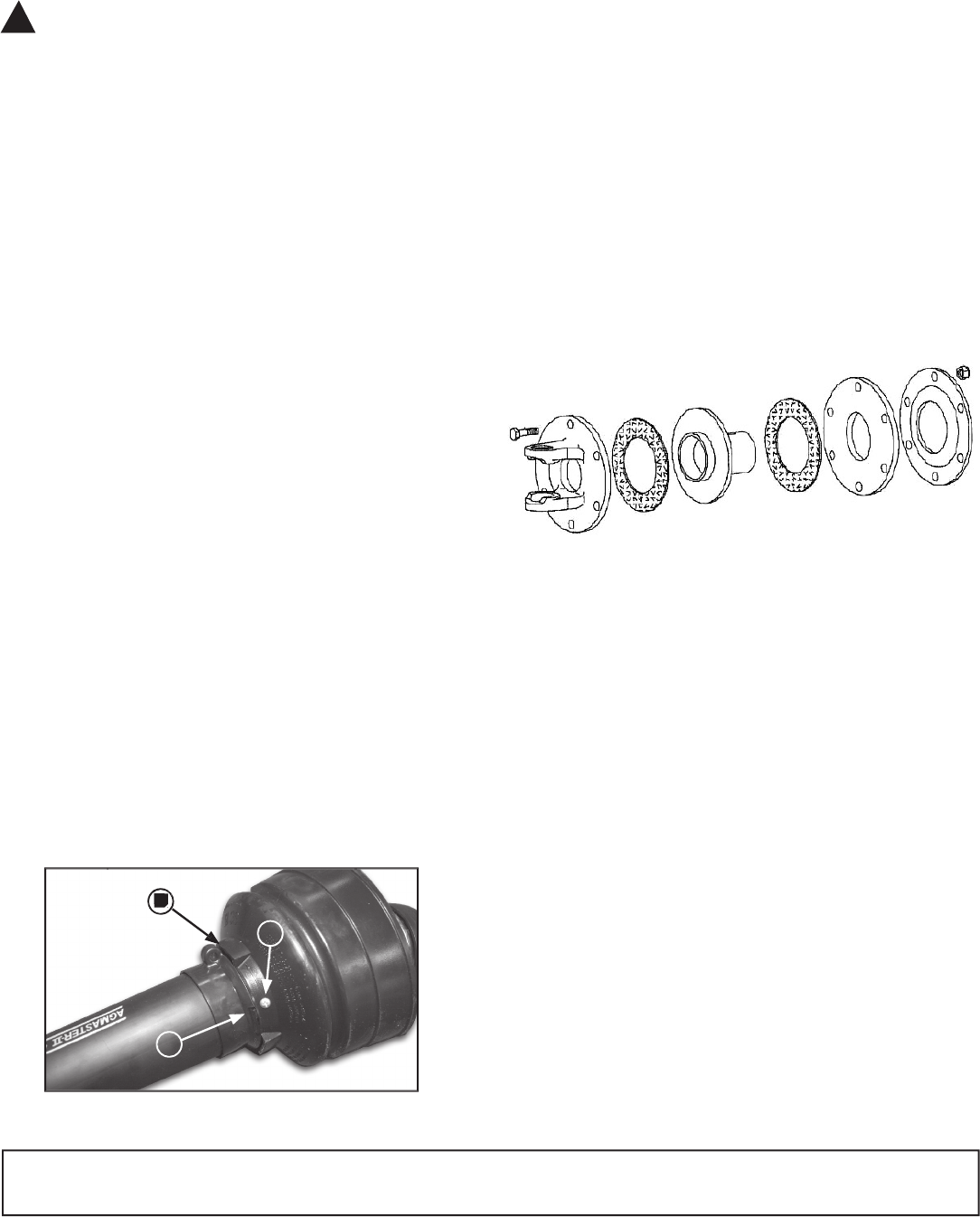

• Disassembling and Inspecting Slip Clutch

1. Remove slip clutch driveline.

(See procedure in this section.)

NOTE:

Belleville springs, which are part of the clutch, keep

tension on all components. When disassembling,

release tension by loosening hardware progressively.

2. Loosen bolts and lock nuts progressively until

tension is relieved.

3. Friction disks may appear to be part of the hub

or yoke, tap lightly on edge to separate.

4. Inspect clutch components for wear or damage.

Repair or replace parts as necessary.

!

B

B

C

B

A

A

B

A

B

• Assembling Slip Clutch

Assemble slip clutch in reverse order of disassembly

using the following instructions:

1. Install belleville spring with concave side

facing away from yoke end.

IMPORTANT: To avoid driveline damage, DO NOT

overtighten bolts and lock nuts. A gap must be left

between clutch plate (B) and belleville spring (C).

2. Tighten bolts and lock nuts progressively,

leaving a gap (A) 4mm, between clutch plate

(B) and Belleville spring (C).

(Service continued on next page)