Attaching 15

ATTACHING

• Assembling PTO Driveline Telescoping

Members (If Necessary)

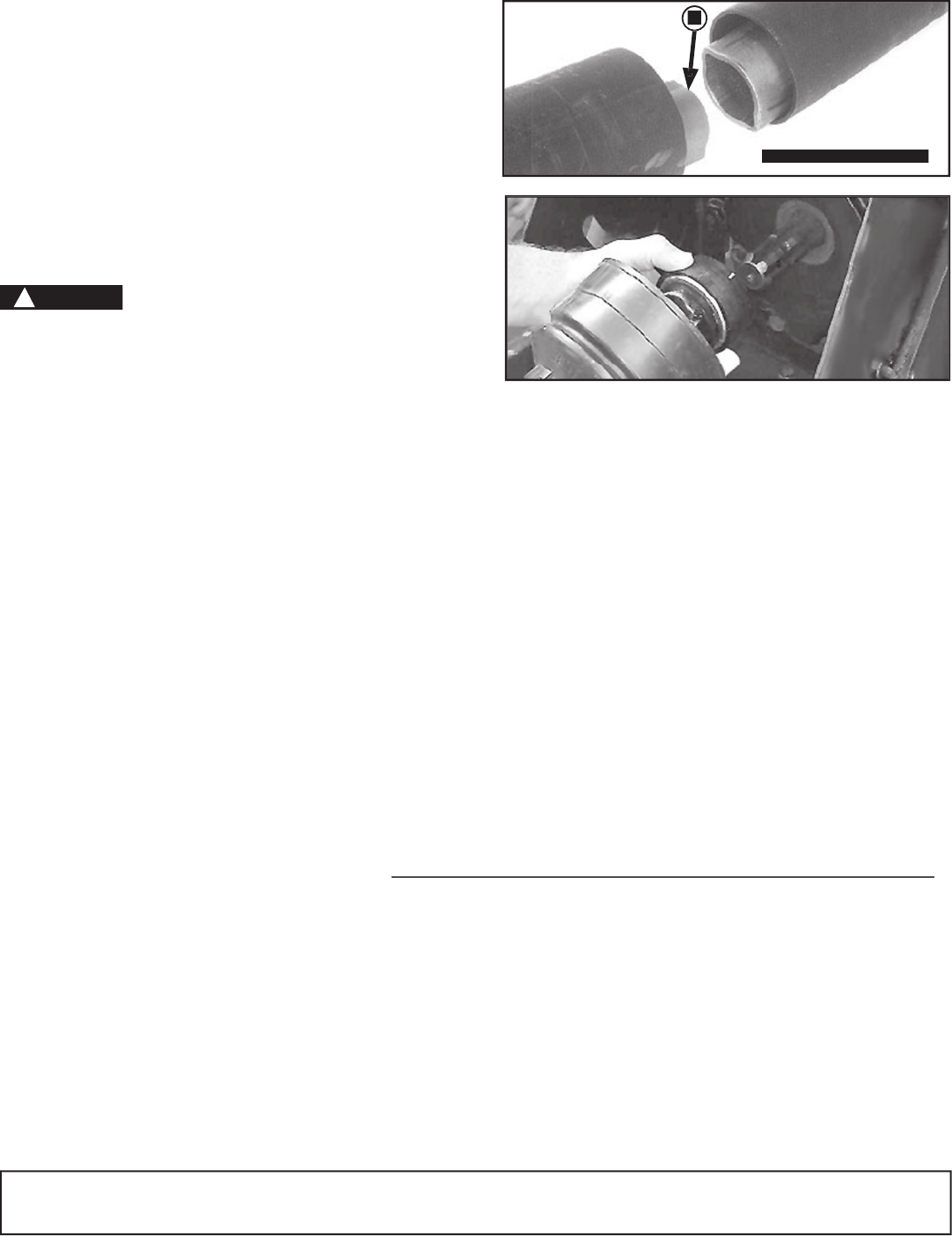

1. Apply multipurpose grease around outside surface

of inner driveline tube (A).

2. Align driveline halves and assemble telescoping

members together.

3.Apply multipurpose grease, or equivalent, to

all lubrication fittings before operating.

(See Lubrication and Maintenance section.)

• Attaching PTO Driveline

Shut off tractor engine before attachi

ng

PTO driveline. Entanglement in rotating

drive

line can cause serious injury or death.

IMPORTANT: Keep driveline and powershaft splines

clean of paint, dirt and chaff. Apply John Deere SD

POLYUREA Grease or equivalent on tractor PTO shaft

before attaching PTO driveline.

1. Shut off tractor engine.

2. Raise tractor PTO shield, if equipped.

IMPORTANT: Do not use bell on driveline to lift

driveline into position. Damage to shielding can occur.

3. Support driveline, cradling it in your hand.

4. Pull collar back toward cutter. Align splines by

rotating cutter driveline. Push driveline onto

tractor PTO shaft until collar snaps into place.

5. Pull back on shield to make sure driveline

is locked.

6. Do not pull back on collar, this will release latch.

7. Lower tractor PTO shield, if equipped.

IMPORTANT: Slip clutch components must be free

to rotate when necessary. After thirty days or more,

linings of slip clutch may draw moisture. Linings

may bond to metal parts causing slip clutch to be

ineffective, resulting in machine damage.

8. Slip clutch operational check.

After the implement has been stored for thirty days

or more perform the following operational check.

a. Loosen bolts and lock nuts progressively until

tension is relieved.

b. To aid in determining slippage, scribe/mark

a line across clutch plate and Belleville Spring.

c. With tractor at idle speed, engage tractor PTO

drive 2 - 3 seconds. Clutch should slip without

turning blades. If clutch does not slip, contact

your authorized dealer.

d. Tighten bolts and lock nuts progressively, leaving a

gap of 4mm, between clutch plate and Belleville spring.

A-Inner Driveline Tube

A

• Checking Driveline/Cutter Clearance

IMPORTANT: Prevent driveline damage from contact

with frame or machine damage from contact with trac-

tor tires. Raise cutter slowly and check for interference.

If necessary, shorten center link or lengthen lift links to

provide clearance to full lift height.

1. Raise cutter slowly and check for clearance

between driveline shield and cutter deck.

2. Check clearance between tractor tires and foot

guards or chain deflector.

3. Check to see if hitch height position will

provide clearance desired.

NOTE:

Final adjustments should be made before operating

cutter. See ADJUSTING CUTTING HEIGHT AND ANGLE

in Operating the Cutter section.

Center link should be

installed in lowest hole at tractor end if there are

multiple holes. Lift height may also be limited by

installing stops on rockshaft control lever bracket.

(continued on next page)

DANGER

!