Dealer Service 21

5WPMAN0242 (Rev. 7/21/2008)

2. Lubricate new cups (6) with a light oil. Place them

in spindle housing (5) so they will mate with cones

(4).

3. Seat cups (6) against machined shoulder of hous-

ing with a press or by placing a large drift on the flat

lip and driving them into housing.

4. Place bottom bearing cone (4) onto spindle shaft

(7) with taper up. Seat on bottom shoulder of shaft

with a press.

5. Insert shaft and bearing cone assembly through

bottom of housing (5).

6. Fill housing cavity with a lithium grease of #2 con-

sistency with a MOLY (molybdenum disulfide) addi-

tive. Place top bearing cone (4) on shaft (7) to mate

with top bearing cup.

7. Install sleeve (3) on shaft and press sleeve and

bearing cone onto shaft until all bearing free play is

removed and there is a slight drag (similar to

adjusting the front wheel bearings on an automo-

bile).

8. Check by spinning spindle. It should turn freely.

9. Be careful not to overtighten bearings. Proper

bearing adjustment is essential to good bearing

life.

10. Should you overtighten bearings, hold spindle

housing and rap spindle shaft with a lead hammer

to loosen bearings. Readjust bearings until proper

setting is obtained.

Proper seal installation is important. An improperly

installed seal will leak and could cause bearing fail-

ure.

11. Pull the rubber portion of seal back and locate

spring.

12. Apply a thin coat of lubricant to bottom seal (2) and

install with spring up toward center of housing.

13. Place bottom seal squarely on housing. Select a

piece of pipe or tubing with an OD that will set on

outside edge of seal. A tube that is too small will

bow seal cage.

14. Carefully press seal into housing, preventing dis-

tortion to metal seal cage. Seal should seat firmly

and squarely against machined shoulder in hous-

ing.

15. Make sure seal lip did not roll under. Distortion to

seal cage or damage to seal lip will cause seal to

leak. Damaged seals must be replaced.

16. Apply a thin coat of lubricant to top seal (2) and

install with spring up away from center of housing.

Top seal should be flush with top of housing.

17. Lubricate spindle with a lithium grease of #2 con-

sistency with a MOLY (molybdenum disulfide) addi-

tive. Vent top seal with blunt edged tool, such as a

letter opener, while filling with grease. Rotate hous-

ing on spindle shaft, checking for free movement.

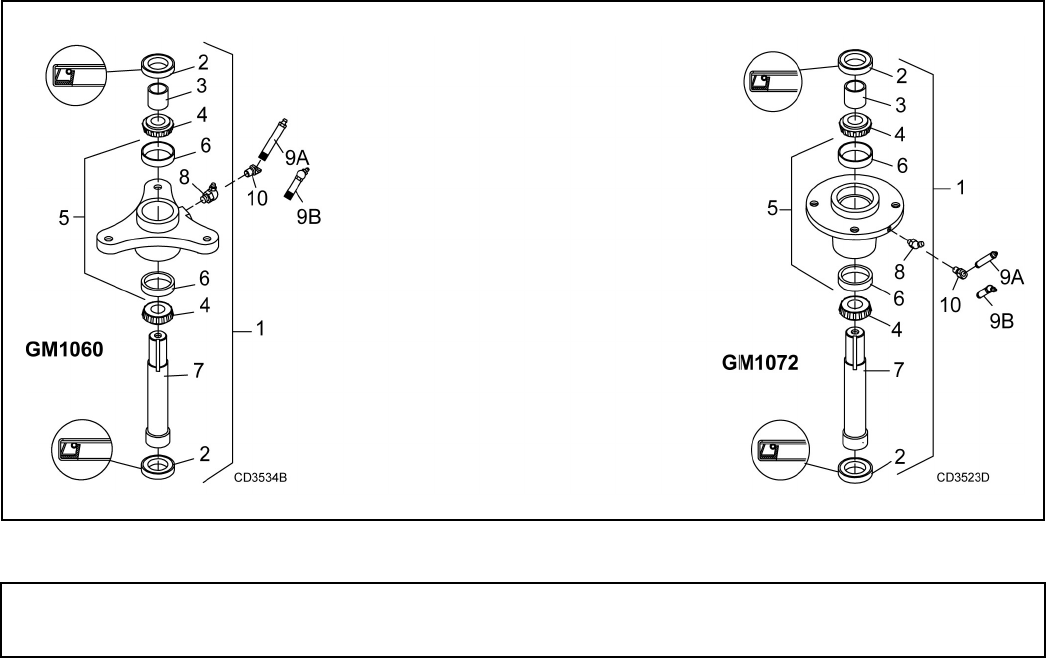

Figure 14. GM1060 & GM1072 Spindle Assemblies

1. Spindle assembly

2. Seal

3. Sleeve

4. Bearing cone

5. Housing & cups

6. Cup

7. Shaft

8. Grease fitting, 1/8 Pipe thread 45°

9A. Grease fitting for right and center

spindles

9B. 30° Grease fitting for left spindle

10. Grease fitting, 45°