Mechanical Drawingss

36 Thermal and Mechanical Design Guidelines

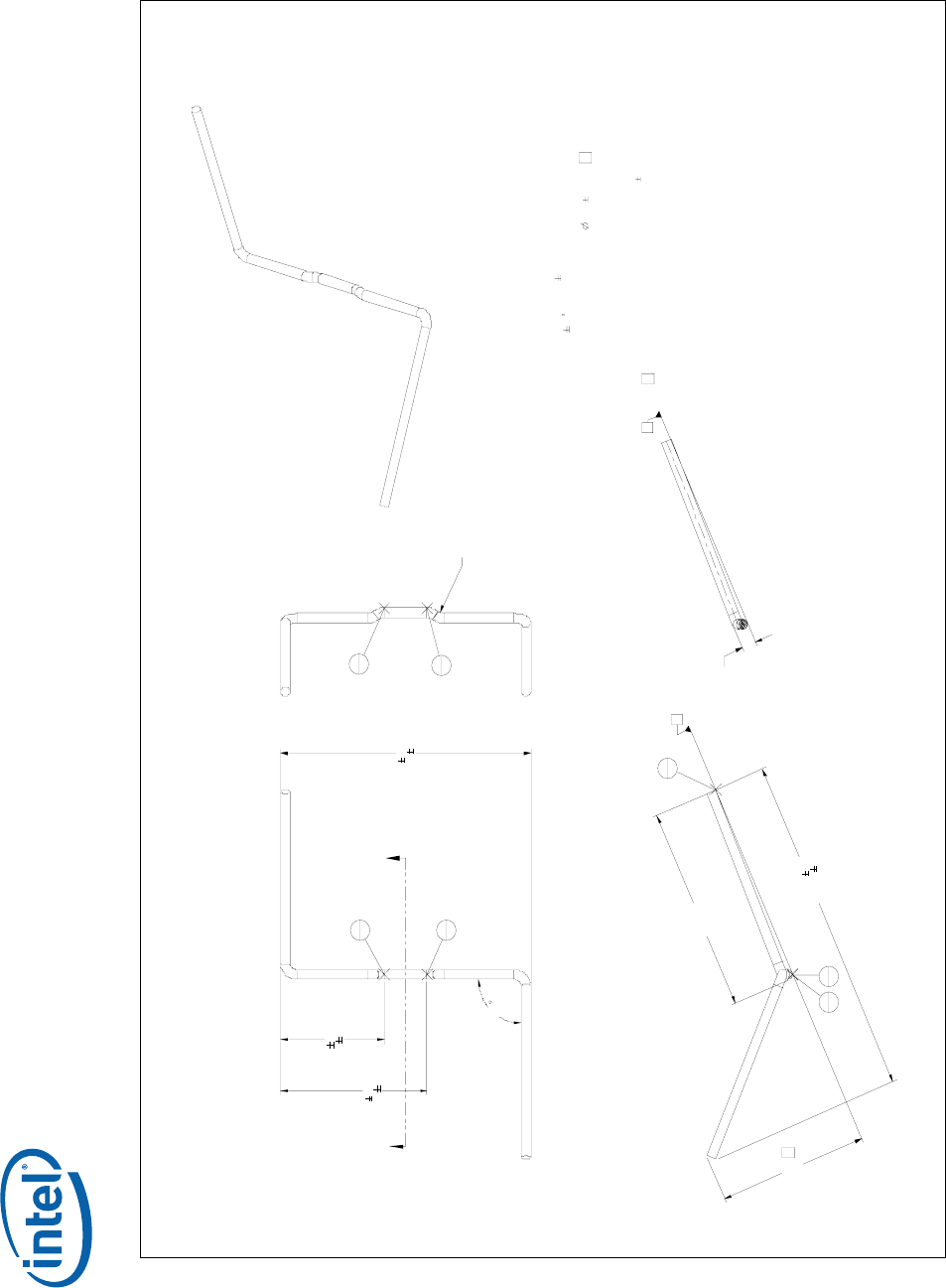

Figure 17. (G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip

A

A

A

A

46.6

0.5

1.8 3 5

.019[]

2X 90

TYP R1.8

.071[]

19.3 0.5

.760

.019[]

27.3 0.5

1.075

.019[]

427.7

1.090[]

61.74 0.5

2.431

.019[]

37.06

1.459[]

2.65

.104[]

NOTES:

1. THIS DRAWING TO BE USED IN CORRELATION WITH SUPPLIED 3D

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS

DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICATED OTHERWISE.

2. TOLERANCES ON DIMENSIONED AND UNDIMENSIONED

FEATURES UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS.

TOLERANCES: LINEAR 0.25

ANGLES: 1

3. MATERIAL:

A) TYPE: ASTM A228 MUSIC WIRE 1.8 0.1MM 4

PLATING: ELECTRO-LESS NICKEL OR EQUIVALENT UPON

INTEL APPROVAL.

B) CRITICAL MECHANICAL MATERIAL PROPERTIES

FOR EQUIVALENT MATERIAL SELECTION:

TENSILE YIELD STRENGTH (ASTM D638) > 965 MPa

FLEXURAL MODULUS (ASTM D638) 210 GPa 10%

4 CRITICAL TO FUNCTION DIMENSION

5. MARK WITH INTEL P/N AND REVISION PER INTEL MARKING

STANDARD 164997; PER SEC 3.8 (POLYETHYLENE BAG)

6. REMOVE ALL SHARP EDGES AND BURRS.

7. ALL DIMENSIONS SHOWN SHALL BE MEASURED FOR FAI

8. ALL SECONDARY UNIT DIMENSIONS ARE FOR REFERENCE ONLY.

FAR SIDE

FA R SIDE

SECTION A-A

A2

A3

A2

A3

A1

A2 A3