8 MHD56391 - Edition 2

TROUBLESHOOTING

This section provides basic troubleshooting information. Specific causes to problems are best identified by thorough inspections performed

by personnel instructed in safety, operation and maintenance of this equipment. The chart below provides a brief guide to common hoist

symptoms, probable causes and remedies.

SYMPTOM

CAUSE REMEDY

Hoist will not operate. Hoist is overloaded. Reduce load to within rated capacity.

Slip clutch not adjusted. Adjust slip clutch. Refer to “MAINTENANCE”

section.

Load continues to move when hoist

is stopped.

Brake is slipping. Check brake adjustment and brake disc wear.

Check brake discs are clean.

Hoist is overloaded. Reduce load to within rated capacity.

Load chain binds. Damaged load chain, pinion shaft, gears or

sheaves.

Disassemble hoist, inspect and repair or replace

damaged components. Refer to

“MAINTENANCE” section.

Load chain not installed properly (twisted,

kinked or “capsized”)

Remove load chain and reinstall.

Hand chain binds. Damaged hand chain, hand chain wheel, pinion

shaft, gears, load chain, sheaves.

Disassemble hoist, inspect and repair or replace

damaged components.

Hand chain not installed properly (twisted or

kinked).

Remove hand chain and reinstall.

Load hook latch does not work. Latch broken. Replace hook latch.

Load hook bent or twisted. Inspect load hook as described in

“INSPECTION” section. Replace if necessary.

MAINTENANCE

WARNING

• Never perform maintenance on the hoist while it is

supporting a load.

• Before performing maintenance, tag hoist:

DANGER - DO NOT OPERATE -

EQUIPMENT BEING REPAIRED.

• Only allow personnel trained in the operation and service of

this product to perform maintenance.

• After performing maintenance on the hoist, test to 125% of

its rated capacity before returning to service. Testing to 150%

of rated capacity will be required to set overload clutch and

might be required to comply with standards and regulations

set forth in areas outside of the USA.

Installing New Load Chain

WARNING

• To prevent a falling load, which can cause death, injury or

property damage, the hook must be on left fall of load chain

and right fall must be attached to hoist body with anchor pin

and anchor hanger. Right and left designations are as viewed

from the hand chain side of the hoist.

NOTICE

• Do not remove the old load chain from the hoist. The old load

chain can be used to install the new load chain.

1. Remove end of load chain from anchor pin.

a. 1/2 to 3 ton units are single fall hoists. The load end of

the load chain is anchored to the bottom hook assembly.

To disconnect the load chain from the bottom hook

assembly remove anchor pin and nut. On bottom hook

remove spring and pin.

b. 5 ton units are double chain fall hoists. The load end of

the load chain is anchored to suspension plates. To

disconnect load chain from suspension plates remove

anchor bolt assembly.

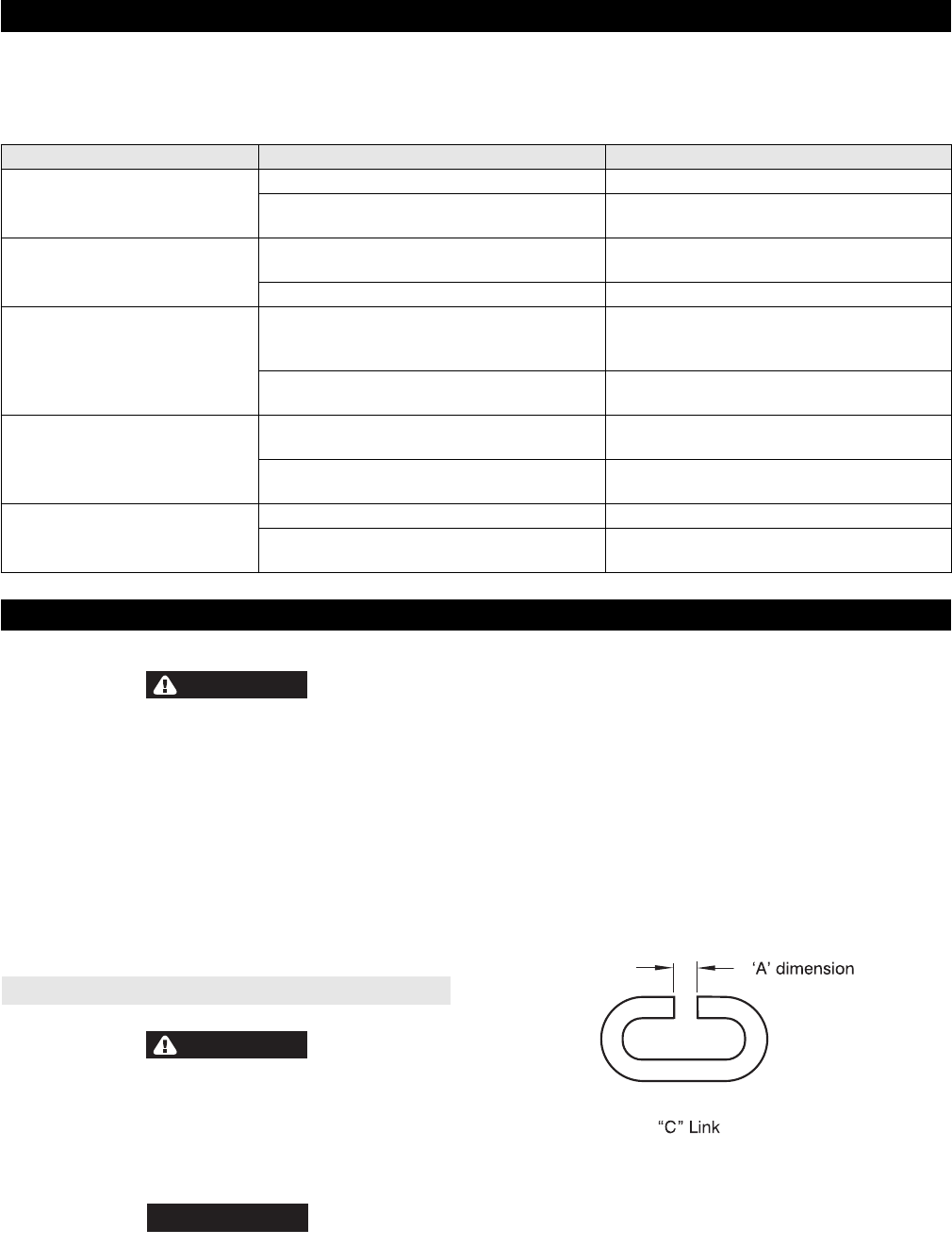

2. Make a “C” link in new load chain by grinding through one

side of the end link. Refer to Dwg. MHP0817 on page 8. To

avoid twisting, the load chain on 2, 3 and 5 ton units must

have an odd number of links, not counting the “C” link.

(Dwg. MHP0817)