12 MHD56391 - Edition 2

Hand Chain Adjustment or Replacement

CAUTION

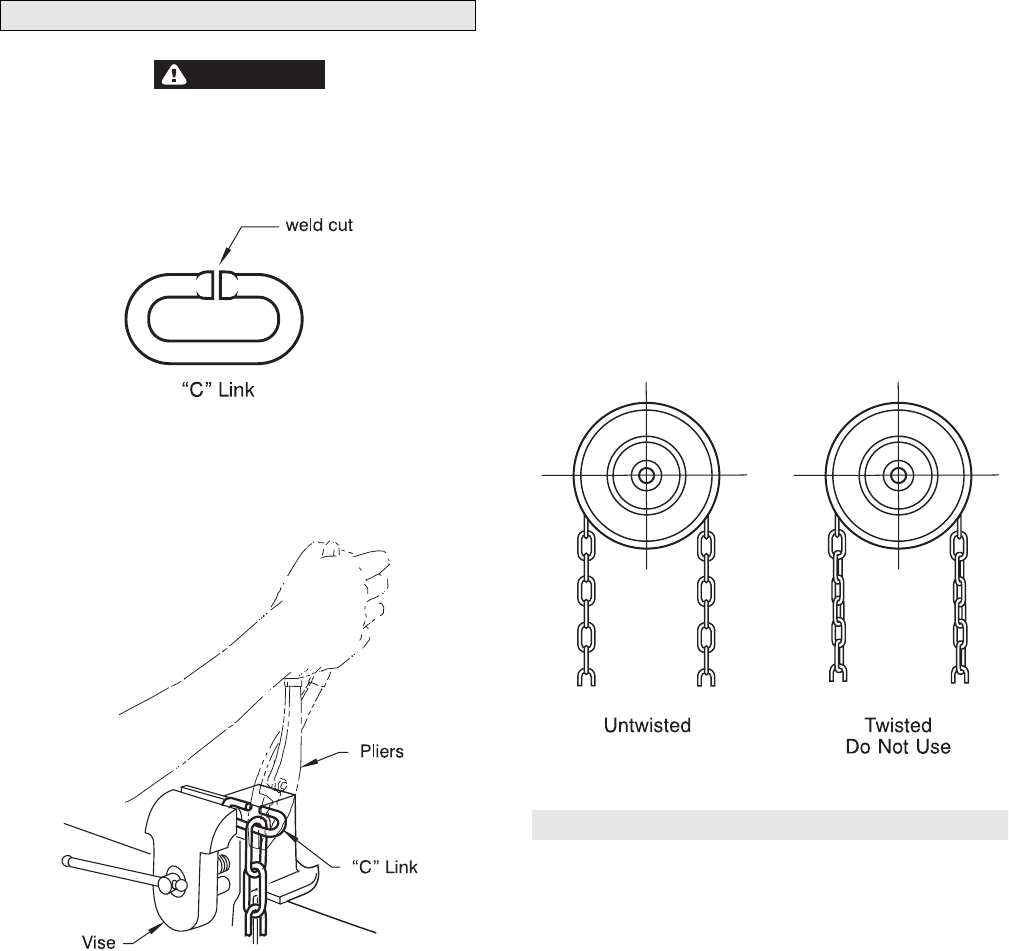

• When cutting the weld side of a hand chain link, do not cut or

nick the opposite side. A damaged link must be replaced to

prevent premature failure. A falling hand chain can cause

injury.

(Dwg. MHP0016)

1. To create a “C” link, cut the welded side of the link with a

hack saw. Clamp one side of the “C” link in a vise and bend it

open by using a pliers to grip the exposed part of the link.

(Dwg. MHP0014)

2. If the hand chain is being replaced, disconnect it at the “C”

link and carefully remove the hand chain.

3. When replacing a hand chain, cut a length 2 times the

required hand chain drop plus about one foot (305 mm). For

adjustments, remove or add a length of chain twice the

difference in hand chain height. To prevent the hand chain

from twisting, maintain an even number of links, by

removing or adding an even number of links.

4. If you are replacing the hand chain, run the new hand chain

up through the left hand chain guide, around the handwheel,

making sure the hand chain is seated in the handwheel

pockets, and back down through the right hand chain guide.

5. Connect the hand chain ends with the “C” link(s), making the

total number of links even, and bend the “C” link(s) shut.

6. Make sure the hand chain is not twisted. If twisted, untwist or

open a “C” link and remove one hand chain link. Refer to

Dwg. MHP0015

on page 12.

(Dwg. MHP0015)

Load Test

Prior to initial use, all new, extensively repaired, or altered hoists

shall be load tested by or under the direction of a person trained in

the operation and maintenance of this hoist, and a written report

furnished confirming the rating of the hoist. Test hoist to 125% of

the rated hoist capacity. Testing to more than 125% will be

required to set overload clutch and may be necessary to comply

with standards and regulations set forth in areas outside of the

USA.