601457_1107 15

WARNING: Never direct discharge of material from mower

deck towards bystanders. Do not operate the mower without

either the discharge chute or the entire grass collection system

in place. Fig. 3-9

Mower deck operation

DANGER: Never attempt to make any adjustments to the

mower deck while the engine is running or with the deck drive

clutch engaged. Mower blades cannot be seen and are located

very close to deck housing. Fingers and toes can be cut off

instantly.

With the engine running, engage the deck clutch switch (Fig. 3-1A & 3-

1B) and advance engine throttle to full rpm.

NOTE: Engaging the deck clutch at high engine rpm or when under

heavy load (in tall grass for example) can cause belts and/or electric clutch to

slip, resulting in premature wear or possible damage.

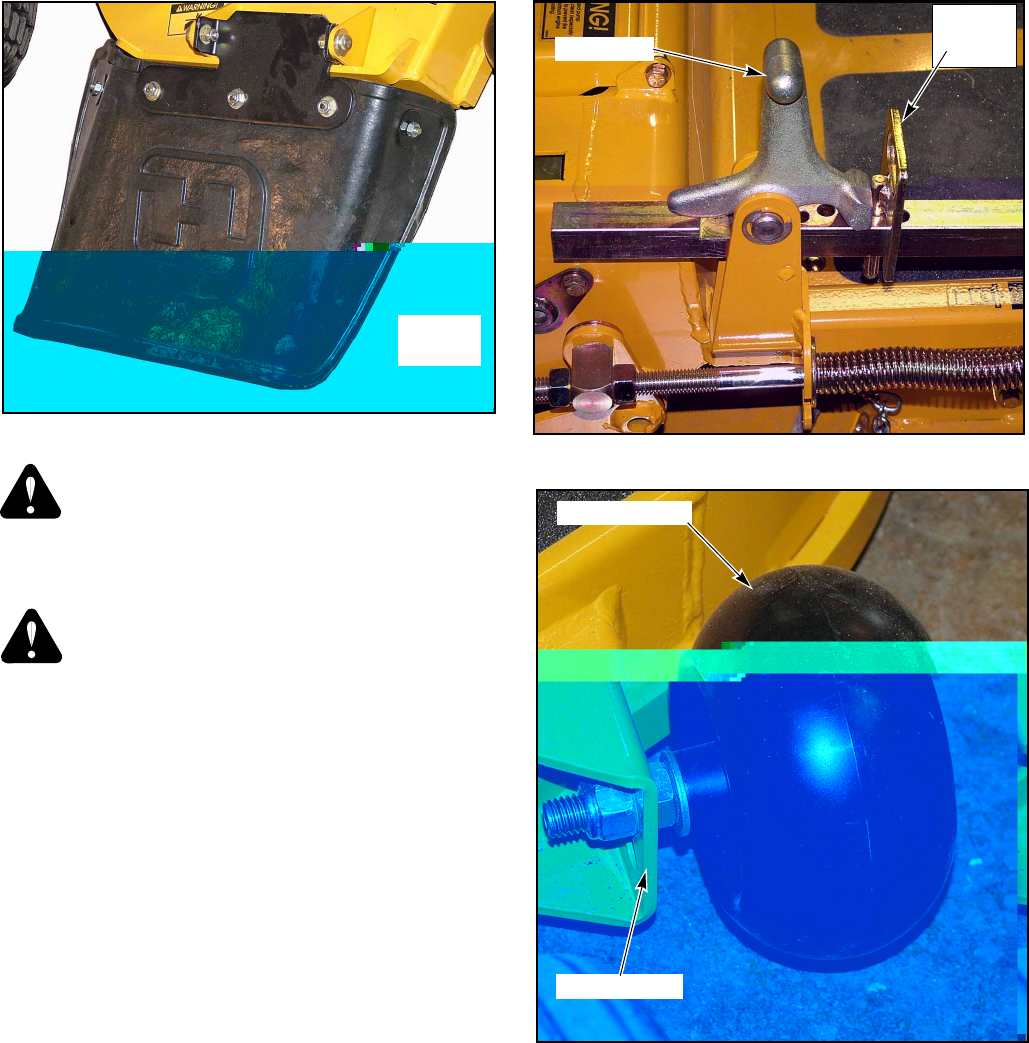

Deck cutting height adjustment

Deck height is adjustable from 1-1/2” to 4-1/2” (3.81 cm - 11.43 cm) in

1/4” increments. The holes in the height adjusting bar are spaced at 1/2”

intervals. By turning the height adjusting stop around, 1/4” increments can

be attained due to the 1/4” plate that is part of the stop. Fig. 3-11

EXAMPLE: When the height adjusting stop is placed in the 1-1/2” (3.81

cm) hole, with the 1/4” (.64 cm) plate facing to the front of the unit, the

cutting height is at 1-1/2” (3.81 cm). When the height adjusting stop is placed

in the 1-1/2” (3.81 cm) hole, with the 1/4” (.64 cm) plate on the operator’s

side of the hole, the cutting height is at 1-3/4” (4.45 cm).

The notch located at the rear of the height adjusting bar is to be used

when the deck is placed in the transport mode.

Anti-scalp wheels

Anti-scalp wheel kits are standard on FasTrak Super Duty units. These

anti-scalp wheels are designed to minimize scalping when mowing on rough

uneven terrain.

After setting the cutting height, adjust the anti-scalp wheels so they

extend below the deck but do not contact the ground. They should always

be at least 1/4” to 3/4” (6.35mm to 19.05mm) below the deck. With the unit

sitting on a flat level surface, the wheel position can be adjusted up or down

as needed from 3/4” to 1-3/4” (19.05mm to 44.45mm) below the blade sur-

face. Move the wheels up or down, in 1/2” (12.70mm) increments, using the

different axle mount holes in the wheel mount bracket. Fig. 3-11

When adjusting the rear anti-scalp wheels, the wheel should be in the

same axle mount hole as the front anti-scalp wheels.

Figure 3-10

Stop handle

Height

adjusting

stop

Figure 3-9

Side

discharge

chute

Figure 3-11

Anti-scalp wheel

Adjusting holes