SERVICE AND ADJUSTMENTS

24

TO REPLACE FUSE

Replace with 30 amp automotive-type plug-in fuse. The

fuse holder is located in the engine compartment, directly

in front of the dash.

TO REPLACE HEADLIGHT BULB

• Raise hood.

• Pull bulb holder out of the hole in the backside of the

grill.

• Replace bulb in holder and push bulb holder securely

back into the hole in the backside of the grill.

• Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your tractor to run

poorly, stop running or prevent it from starting.

• Check wiring. See the electrical wiring diagram in the

Repair Parts section of this manual.

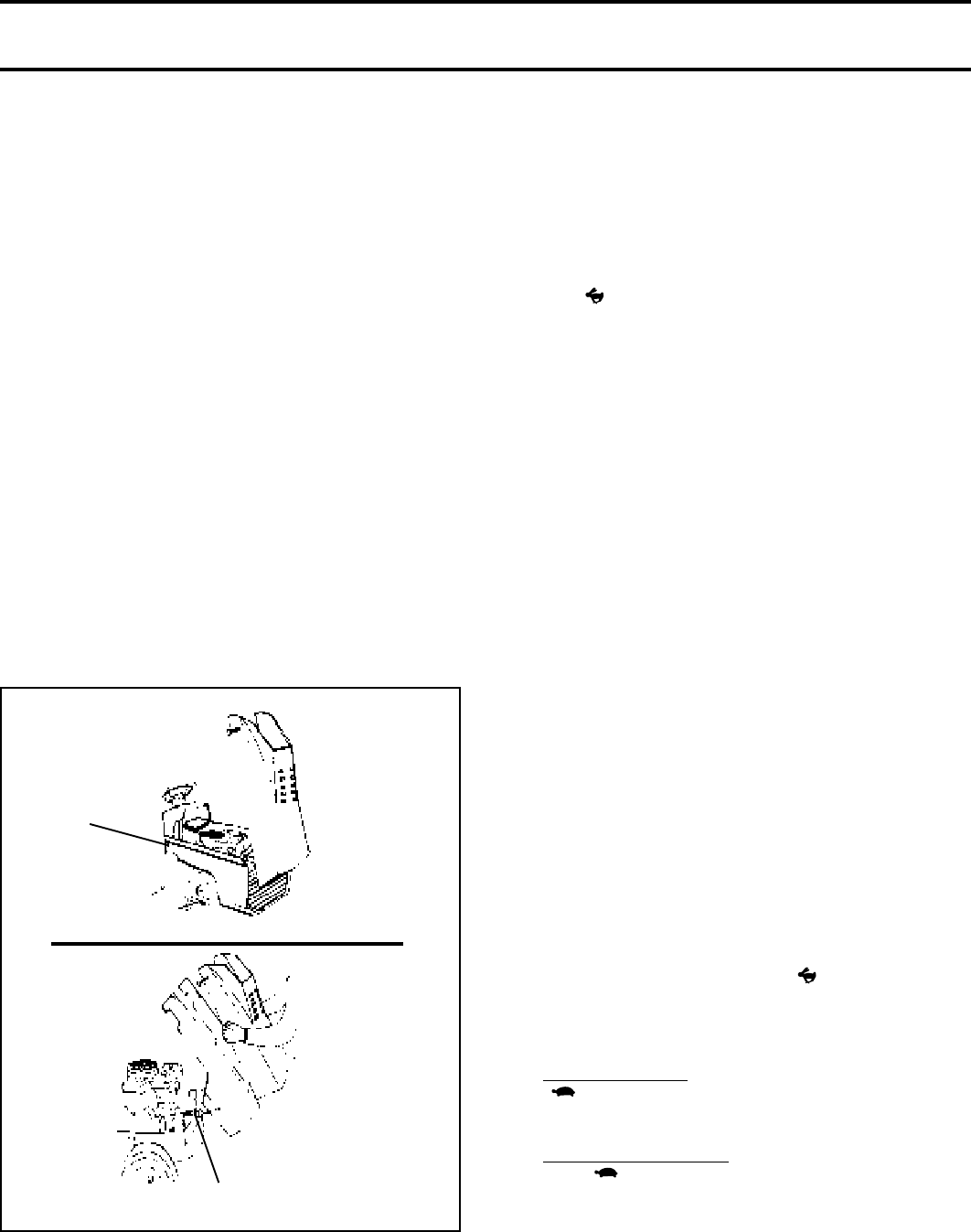

TO REMOVE HOOD AND GRILL ASSEMBLY

(See Fig. 35)

• Lift hood. Disconnect headlight wiring connection.

• Remove wingnut at rear of each side panel.

• Remove retainer springs from hood pivot brackets.

• Pivot hood and side panel forward and lift off tractor.

• To replace, reverse above procedure.

FIG. 35

WINGNUT

HEADLIGHT WIRING CONNECTION

ENGINE

TO ADJUST THROTTLE CONTROL CABLE

(See Figs. 36 & 37)

The throttle control has been preset at the factory and

adjustment should not be necessary. Check adjustment as

described below before loosening cable. If adjustment is

necessary, proceed as follows:

• With engine not running, move throttle control lever to

fast ( ) position.

• Check that speed control lever is against stop screw. If

it is not, loosen casing clamp screw and pull throttle

cable until lever is against screw. Tighten clamp screw

securely.

TO ADJUST CARBURETOR (See Fig. 38)

The carburetor has been present at the factory and adjust-

ment should not be necessary. However, minor adjustment

may be required to compensate for differences in fuel,

temperature, altitude or load. If the carburetor does need

adjustment, proceed as follows:

In general, turning the adjusting needles in (clockwise)

decreases the supply of fuel to the engine giving a leaner

fuel/air mixture. Turning the adjusting needles out (coun-

terclockwise) increases the supply of fuel to the engine

giving a richer fuel/air mixture.

IMPORTANT: DAMAGE TO THE NEEDLES AND THE

SEATS IN CARBURETOR MAY RESULT IF SCREW IS

TURNED IN TOO TIGHT.

PRELIMINARY SETTING -

• Be sure you have a clean air filter, and the throttle

control cable is adjusted properly (see above).

• With engine off turn idle fuel adjusting needle in (clock-

wise) closing it finger tight and then turn out (counter-

clockwise) 1-1/4 turns.

• Turn main fuel adjusting needle in (clockwise) closing

finger tight and then turn out (counterclockwise) 1 turn.

FINAL SETTING -

• Start engine and allow to warm for five minutes. Make

final adjustments with engine running and shift/motion

control lever in neutral (N) position.

• With throttle control lever in fast ( ) position, turn main

fuel adjusting needle in (clockwise) until engine begins

to die then turn out (counterclockwise) until engine

runs rough. Turn needle to a point midway between

those two positions.

•

Idle speed setting - With throttle control lever in slow

(

) position, engine should idle at 1400 RPM. If

engine idles too slow or fast, turn idle speed adjusting

screw in or out until correct idle is attained.

•

Idle fuel needle setting - With throttle control lever in

slow (

) position, turn idle fuel adjusting needle in

(clockwise) until engine begins to die and then turn out

(counterclockwise) until engine runs rough. Turn needle

to a point midway between those two positions.

• Recheck idle speed. Readjust if necessary.