20 – English

Maintenance

Ignition system

The engine is equipped with an electronic ignition system.

Only the spark plug requires maintenance.

For recommended spark plug, see Technical data.

Replacing the spark plug

1 Remove the ignition cable shoe and clean around the

spark plug.

2 Remove the spark plug with a 3/4” (19 mm) spark plug

socket wrench.

3 Check the spark plug. Replace the spark plug if the

electrodes are burned or if the insulation is cracked or

damaged. Clean the spark plug with a steel brush if it is to

be reused.

4 Measure the electrode gap with a gapping tool. The gap

should be 0.75 mm/0.030”. Adjust as necessary by

bending the side electrode.

5 Reinsert the spark plug, turning by hand to avoid

damaging the threads.

6 Tighten the spark plug, once it touches the seating, with

the spark plug spanner. Tighten the spark plug so that the

washer is compressed. A used spark plug should be

turned 1/8 of a turn from the seated position. A new spark

plug should be turned a 1/4 turn from the seated position.

7 Replace the ignition cable shoe.

Check the safety system

The Rider is equipped with a safety system that requires the

following conditions.

The engine can only be started when:

• The cutting deck is raised and the parking brake is

applied.

The engine should stop when:

• The cutting deck is lowered and the driver rises from the

seat.

• The cutting deck is in its raised position, the parking brake

is not applied and the driver rises from the seat.

Check daily to ensure that the safety system works by

attempting to start the engine when one of the conditions

above is not met. Change the conditions and try again.

Main fuse

The main fuse is placed in a detachable holder under the

battery case’s cover, in front of the battery.

Type: Flat pin, 15 A.

Do not use any other type of fuse when replacing.

A blown fuse is indicated by a burnt connector. Pull the fuse

from the holder when replacing.

The fuse is there to protect the electrical system. If it blows

again shortly after replacement, it is due to a short circuit,

which must be fixed before the machine can be put into

operation again.

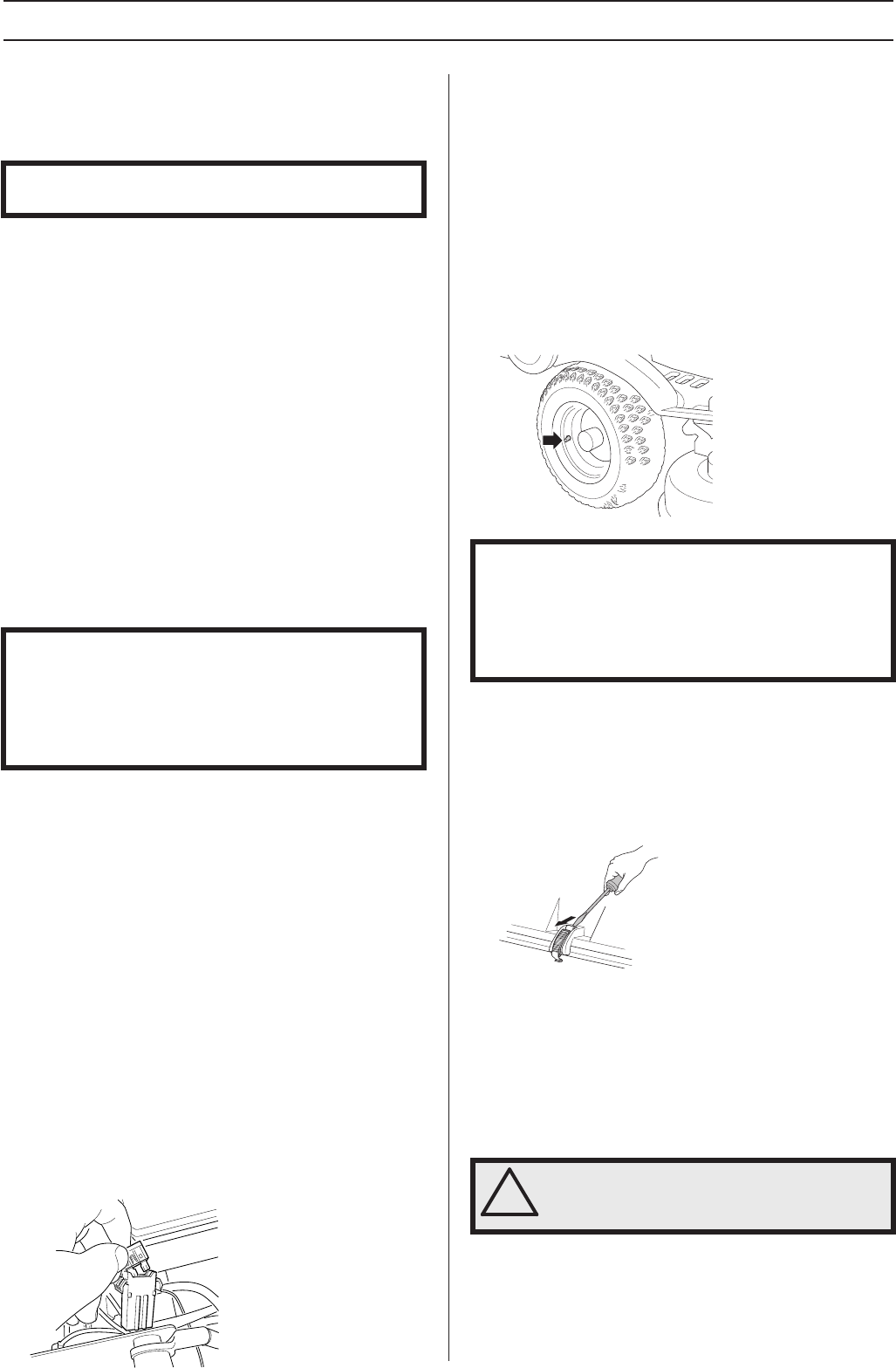

Checking the tyre pressure

The tyre pressure should be 60 kPa (0.6 bar / 9 PSI) all round.

To improve driving the pressure on the rear tyres can be

reduced to 40 kPa (0.4 bar/5.6 PSI). The maximum tyre

pressure is 100 kPa (1,0 bar/14 PSI).

Checking the engine’s cooling air

intake

Clean the air intake grille in the engine cover behind the

driver’s seat.

Open the engine cover.

Check that the cooling intake is free from leaves, grass and

dirt.

Check the air duct, located on the inside of the engine cover,

ensure it is clean and does not rub against the cooling air

intake.

A blocked cooling intake will interfere with the cooling of the

engine, which can damage the engine.

IMPORTANT INFORMATION

Fitting the wrong spark plug type can damage the engine.

IMPORTANT INFORMATION

Inadequately tightened spark plugs can cause overheating

and damage the engine. Tightening the spark plug too

much can damage the threads in the cylinder head.

Do not turn over the engine if the spark plug or ignition cable

has been removed.

IMPORTANT INFORMATION

Different tyre pressures on the front tyres will result in the

blades cutting the grass at different heights. Having the

same air pressure in the tyres is important in order to

achieve the best possible performance as well as to avoid

damage to the machine

!

WARNING! The cooling air intake rotates

when the engine is running. Mind your

fingers.