English-52

LUBRICATION

Lubricating the Cables

If possible, grease both ends of the cables and move the controls to end stop positions when lubricating.

Refit the rubber covers on the cables after lubrication. Cables with sheaths will bind if they are not

lubricated regularly. If a cable binds, it can disrupt operation.

If a cable binds, remove the cable and hang it vertically. Lubricate it with light engine oil until the oil begins

to escape from the bottom.

Tip: Fill a small plastic bag with oil and tape it so that it seals against the sheath and allow the cable to hang

vertically from the bag overnight. If you do not succeed in lubricating the cable, it must be replaced.

Shaft Bushings and Linkage

Lubricate the bearings of the shafts and

linkage for the brake system and steering

with oil spray or oil can.

Lubricating in Accordance with the

Lubrication Schedule

1. Hydraulic System, Oil Level

The hydraulic oil and filter should be replaced

every 300 hours, and at least once a year.

Contact an authorized service workshop.

Check the oil level in the hydraulic tank daily.

The level shall be about 3/4"-1"

(19 - 25 mm) below the top of the tank.

Check connections, hoses, and tubes for

damage or leaks. Replace or repair if

doubtful.

Changing Oil and Filters

Oil and filter changes should be carried out

by an authorized service workshop due to the

risk of impurities enter the system.

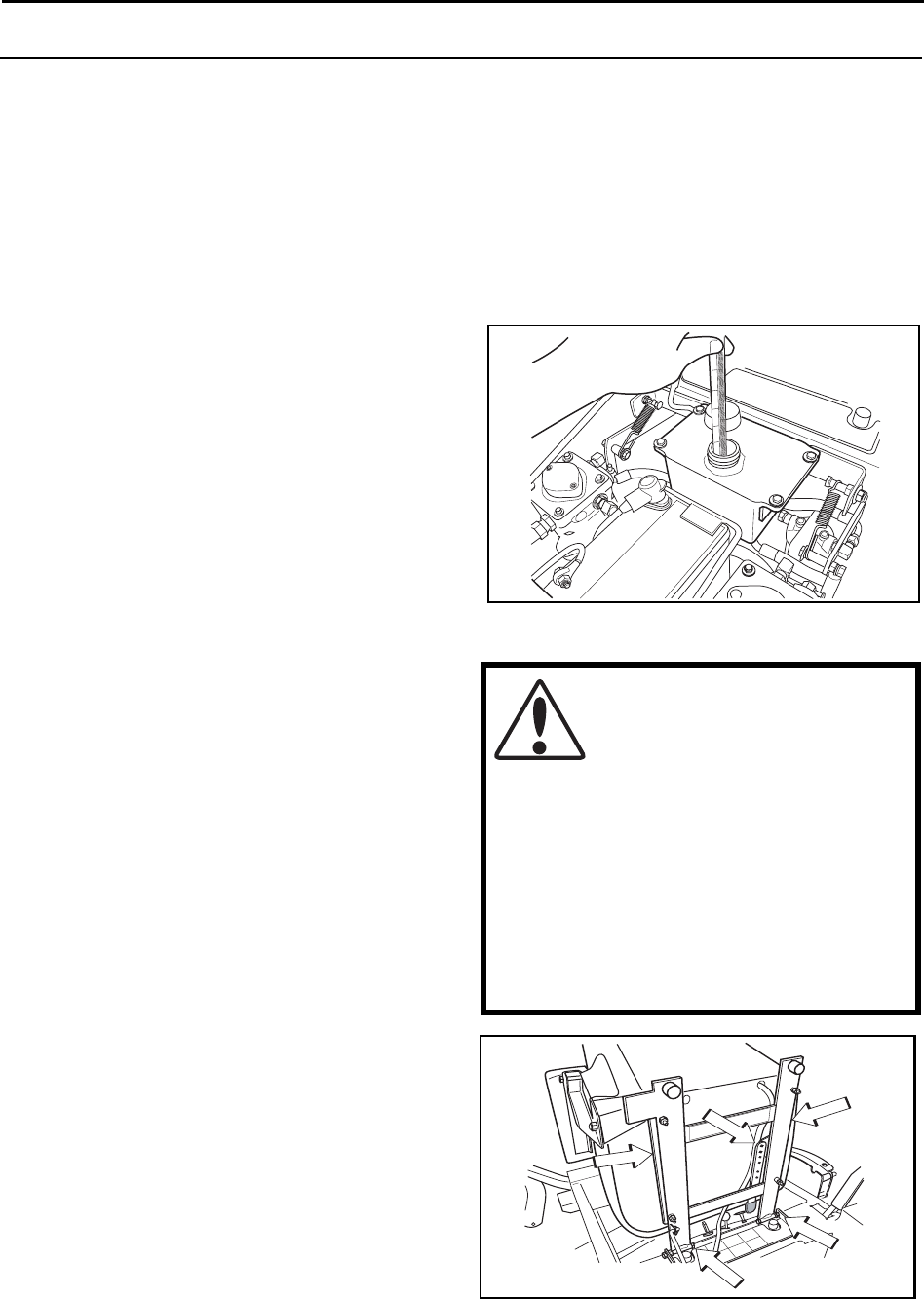

2. Driver’s Seat

Tip the seat.

Lubricate the hinges at the front of the seat

usinganoilcan.

Lubricate the seat slide adjustment and lever

mechanism with the oil can.

8011-565

Checking the hydraulic oil

WARNING!

If a leak is suspected, use a

piece of cardboard or wood,

NOT your hands, to check for

leaks. Escaping hydraulic oil

under pressure can have

sufficient force to penetrate the

skin, causing serious injury.

If injured by escaping fluid, see

a doctor at once. Serious

infection or reaction can

develop if proper meical

treatment is not administered

immediately.

8011-57

1

Lubricating the lengthways adjuster under the seat