33

TROUBLE SHOOTING GUIDE

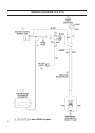

Engine Will Not Start:

Cause Action

Electrical switches not in correct position. Check that BOTH Emergency Stop Switch (AA) and Engine

Start Switch (DD) (FS 513) are in “ON” position. Emergency

Stop Switch (AA) should be pulled outward from cowl, and

Engine Start Switch (DD) turned to “1” (ON) position.

Fuel valve closed. Open the fuel valve.

Choke valve open. Close the choke with cold engine.

Fuel tank empty. Fill with fuel.

Contamination, or water ice in fuel system. Clean tank, fuel lines and carburetor. Fill tank with fresh fuel.

Buildup on spark plug electrodes. Check electrode gap and clean.

Engine has no power or runs unevenly. Air lter Clogged. Clean or replace the air lter.

Diamond Blade Trouble Shooting:

Problem Cause & Action

Loss of Tension in Diamond Blade Blade being used on misaligned saw. Check for proper saw alignment.

Blade is excessively “hard” for material being cut, creating stress on steel blade

center. Check that blade is correct for material being cut.

Different diameter or undersize blade anges creates uneven pressure on blade

center. Use proper size ange on each side of blade. Never use worn or dam-

aged anges.

Blade operated at improper speed (R.P.M.). Make certain blade shaft is turning at

the proper speed (R.P.M.) for blade size. Check R.P.M. using a tachometer.

Blade improperly mounted on arbor. Could become bent when anges are tight-

ened.

Segment Loss Blade is too “hard” for material being cut. Use “softer” blade specication.

Overheated blade, detected as “blue” color on steel center. Check that water

supply is adequate and not blocked.

Saw is twisted while cutting. Saw only in a straight line.

Blade Bore is worn to an eccentric shape (ovalized). Replace worn blade and

worn spindle.

Segment knocked off during mounting our transport. Avoid rough handling of

diamond blade. Never transport the machine with the diamond blade mounted.

Cracked Blade Core Blade is too “hard” for material being cut. Use “softer” blade specication.

Overheated blade, detected as “blue” color on steel center. Check that water

supply is adequate and not blocked.

Saw is twisted while cutting. Saw only in a straight line.

Cracked Blade Segments Blade is too “hard” for material being cut. Use “softer” blade specication.

Blade operated at improper speed (R.P.M.). Make certain blade shaft is turning at

the proper speed (R.P.M.) for blade size. Check R.P.M. using a tachometer.

WARNING!

DO NOT use damaged diamond blades!

Death or injury could occur if machine is op-

erated using damaged diamond blades!