1. Never store unused material in spreader. Return

unused product to its original container.

2. Open and wash spreader thoroughly after each

use and dry completely in sun or heated area.

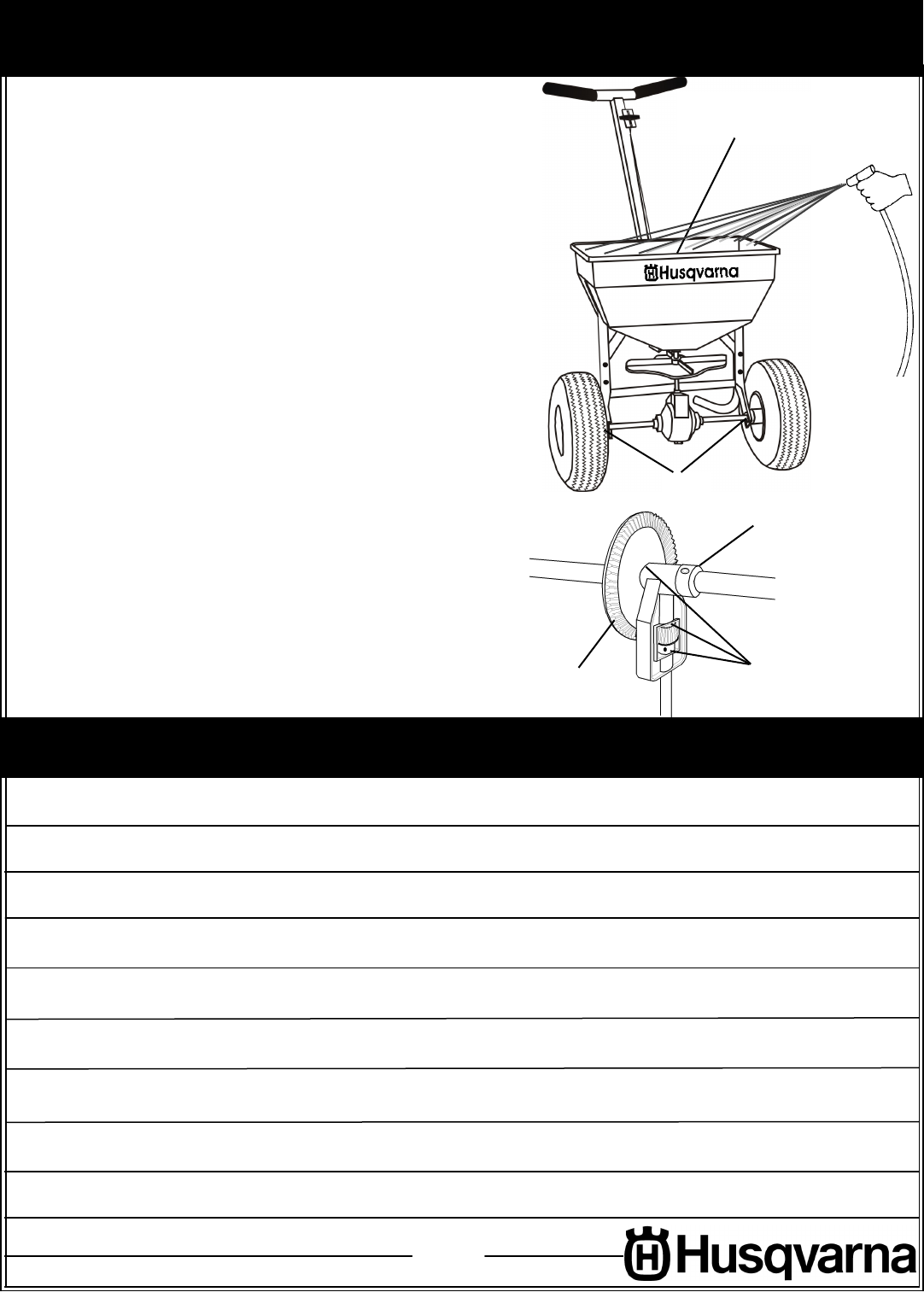

3. Oil the axle bearings, impeller shaft bearing in

hopper.

4. Remove gear cover and wash gears thoroughly.

Oil all bearing areas and face of gear teeth. Re-

install gear cover.

5. Gear mesh should be checked on a regular basis

during high use periods. Clearance between the

axle gear and pinion gear should be minimal but not

tight. If adjustment is necessary, loosen axle collar

set screw and hold gears together. Slide axle collar

against the gear support and tighten axle collar set

screw. Spin drive wheel. Gears should run freely

and smoothly.

6. Impeller surface should be cleaned periodically to

remove build-up of product. Build-up can cause the

spread pattern to change.

7. Tire pressure should be 20-25 PSI.

MAINTENANCE

MAINTENANCEMAINTENANCE

MAINTENANCE

Oil Impeller Shaft

Bearing In Hopper

Axle Collar

Oil

Oil

Oil

NOTES

NOTESNOTES

NOTES

7