9

PROEDGE SERIES BLADES

The ProEdge Line of beveled diamond blades is especially designed for architectural scoring to replace labor-intensive hand

tooling. These specialty blades are ideal for residential and commercial applications to chase standard joints for a beveled look.

Chasing cuts using the ProEdge blades would begin the next day or later after the concrete is placed and control joints have

been made. Choose the correct specication of ProEdge blade to suit your particular needs

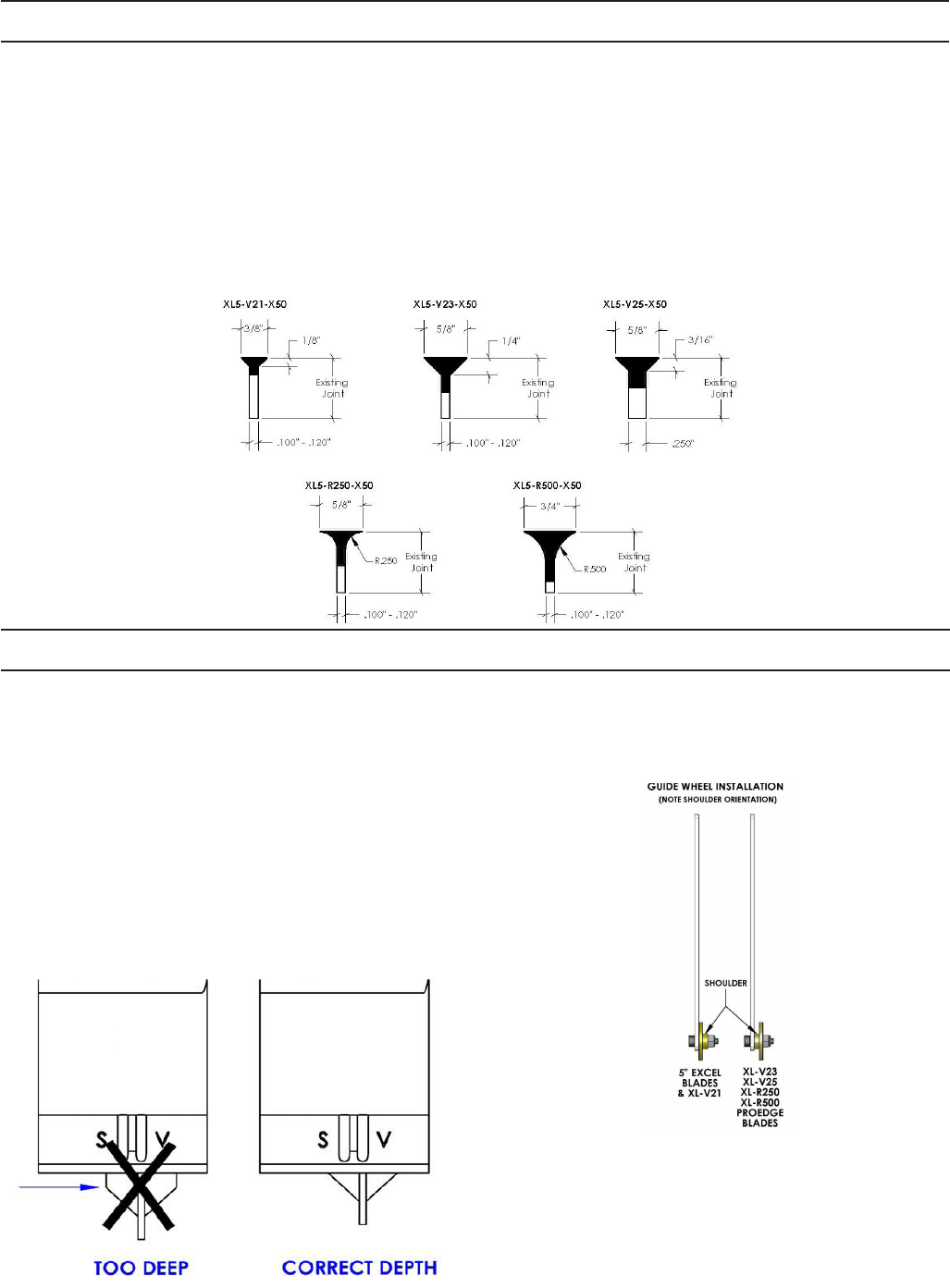

ProEdge V-Blade XL5-V21-X50 3/8” (9.53mm) wide bevel blade for existing 0.100” (2.54mm) wide saw cut

XL5-V23-X50 5/8” (15.88mm) wide bevel blade for existing 0.100” (2.54mm) wide saw cut

XL5-V25-X50 5/8” (15.88mm) wide bevel blade for existing 0.250” (6.35mm) wide saw cut

ProEdge Radius Blade XL5-R250-X50 5/8” (15.88mm) wide bevel blade for existing 0.100” (2.54mm) wide saw cut

XL6-R500-X50 3/4” (19.1mm) wide bevel blade for existing 0.100” (2.54mm) wide saw cut

Choose the correct specication of ProEdge Blade based on the width of the pre-existing control joint as follow:

USING THE PROEDGE SERIES BLADES

Follow the instructions for installing a Excel series blade and

skid plate when installing a ProEdge blade.

NOTE:

The ProEdge blade requires its own unique skid plate to

function properly.

Step 1

Adjust bevel depth of cut by loosening the depth adjust arm.

Pull up on the lower guard until the proper amount of blade

protrudes below the skid plate. (See gure below for proper

depth).

Step 3

Line up the saw by pushing down on the saw lower the blade

into the existing cut. Use the “V” notch on the front of the

lower guard to ne tune alignment. Flip the lock-off button and

squeeze the paddle switch to turn “ON” the saw. Allow the

blade to reach maximum speed the rotate the saw down to

plunge the blade into the concrete until the depth adjust arm

bottoms down against the depth stop bolt.

Step 4

Push the saw forward to cut, keeping the guide wheel on the

cut line. Maintain an even cutting speed for best results.

Step 2

Set the depth adjust arm rmly against the depth stop bolt and

tighten the depth adjust thumb screw to set the depth. Remove

the guide wheel and reinstall with the shoulder against the

guide arm (See illustration: Guide wheel installation).