20

MAINTENANCE

Carburetor

Your Husqvarna product has been designed

and manufactured to specifications that re-

duce harmful emissions. After the engine

has used 8--10 tanks of fuel, the engine will

be run--in. To ensure that it continues to run

at pea k performance and to minimize harm-

ful exhaust e missions after the run--in peri-

od, ask your servicing dealer to adjust your

carburetor.

The owner is responsible

f

or the per

f

or-

mance of all required m aintenance as

defined in the operator’ s manu al.

W ARNING: The com plete clutch,

clutch cove r , a nd shaft must be

fitted before the machine is started,

otherwise parts co uld come loose

and cause personal injury.

Function

S The carburetor governs the engine’s

speed via the throttle control. Air and fuel

are mixed in the carburetor.

S The T--screw regulates the throttle setting

at idle speed. If the T--screw is turned

clockwise this gives a high er idle speed;

turning it counterclockwise gives a lower

idle speed.

Basic setting

S The basic carburetor settings are ad-

justed during testing at the factory. Fine

adjustment should be carried out by a

skilled technician.

Rec. idle speed:

See “Technical data” section.

Recommended max. speed:

See “Technical data” section.

Fine adjustment of the idle speed--T

Adjust the idle speed using the idle adjust-

ment screw--T if it is necessary to readjust.

First, turn the idle adjustment screw--T

clockwise until the cutting attachment starts

to rotate. Then, turn the screw counter-

clockwise until the cutting attachment stops.

The idle speed is correctly adjusted when

the engine will run smoothly in every posi-

tion. The idle speed should also be well

below the speed at which the cutting attach-

ment starts to rotate.

CAUTION! If the cutting attachment rotates

when the engine is idling the idle adjustment

screw T should be turned counterclockwise

until the cutting attachment stops.

Idle Speed

Screw--T

W ARNING: If the idle speed can-

not be adjusted so that the cutting

attachm ent stops, co ntact your se r-

vicing dealer . Do not use the ma-

chine until it has been correctly ad-

justed or repaired.

Unit/Maintenance Safety

Disconnect the spark plug before perform-

ing maintenance, except carburetor adjust-

ments.

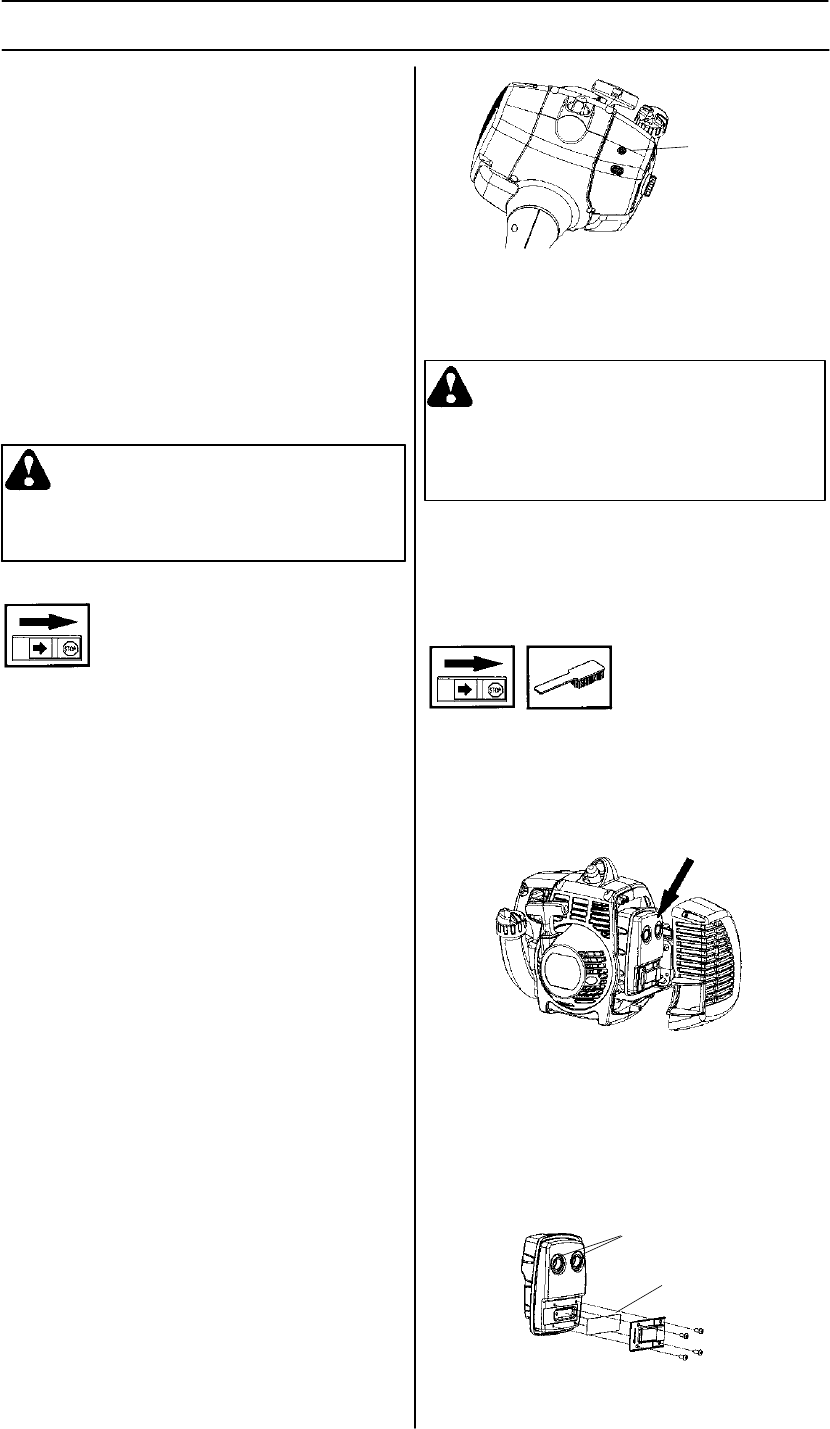

Muffler

The muffler is designed to reduce the noise

level and to direct the exhaust gases away

from the operator. The exhaust g ases are

hot a nd can contain sparks, which may

cause fire if directed against dry and com-

bustible material.

Muf flers are equipped with a special spark

arrestor mesh. You should clean the mesh

at least once a month. This is best done

withawirebrush.If the mesh is damaged

it s hould be replaced. A blocked mesh

will cause the machine to overheat and re-

sult in damage to the cylinder and piston.

Muf fler bolts

CAUTION! Never use a machine that has

a faulty or loose m uffler. Ensure the muffler

bolts are tight.

Spark arrestor mesh