MAINTENANCE

English – 35

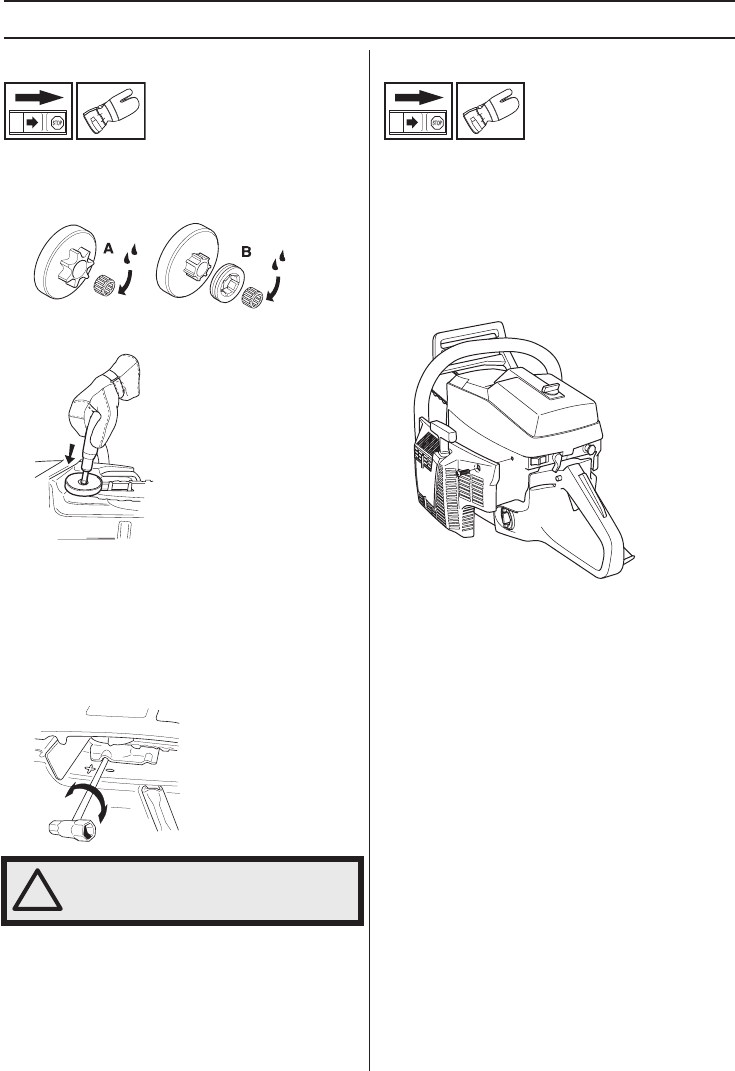

Needle bearing lubrication

The clutch drum is fitted with one of the following drive

sprockets:

•

A Spur sprocket (the chain sprocket is welded on the drum)

•B Rim sprocket (replaceable)

• Both versions have a needle bearing on the drive shaft,

which has to be g

reased regularly (once a week).

NOTE! Use a high-quality bearing grease or engine oil.

Adjustment of the oil pump

The oil pump is adjustable. Adjustments are made by

turning the screw using a screwdriver or combination

spanner. The machine is supplied from the factory set to

1 turn open. Turning the screw clockwise will reduce the

oil flow and turning the screw anti-clockwise will increase

the oil flow.

Recommended settings:

These recommendations apply to Husqvarna’s chain oil,

f

or other chain oils increase the oil flow by one step.

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

1 Air intake on the starter.

2 Air guide plate.

3 Fins on the flywheel.

4 Cooling fins on the cylinder.

5 Cylinder cover (directs cold air over the cylinder).

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

!

WARNING! The engine must not be

running when making adjustments.

Bar 24"-28": 0 turns from the closed position.

Bar 28"-34": 3/4 turns from the closed position.

Bar 34"-42": 1 1/2 turns from the closed position.

Bar 42" and longer:

1 3/4 turns from the closed position.