MAINTENANCE

38 – English

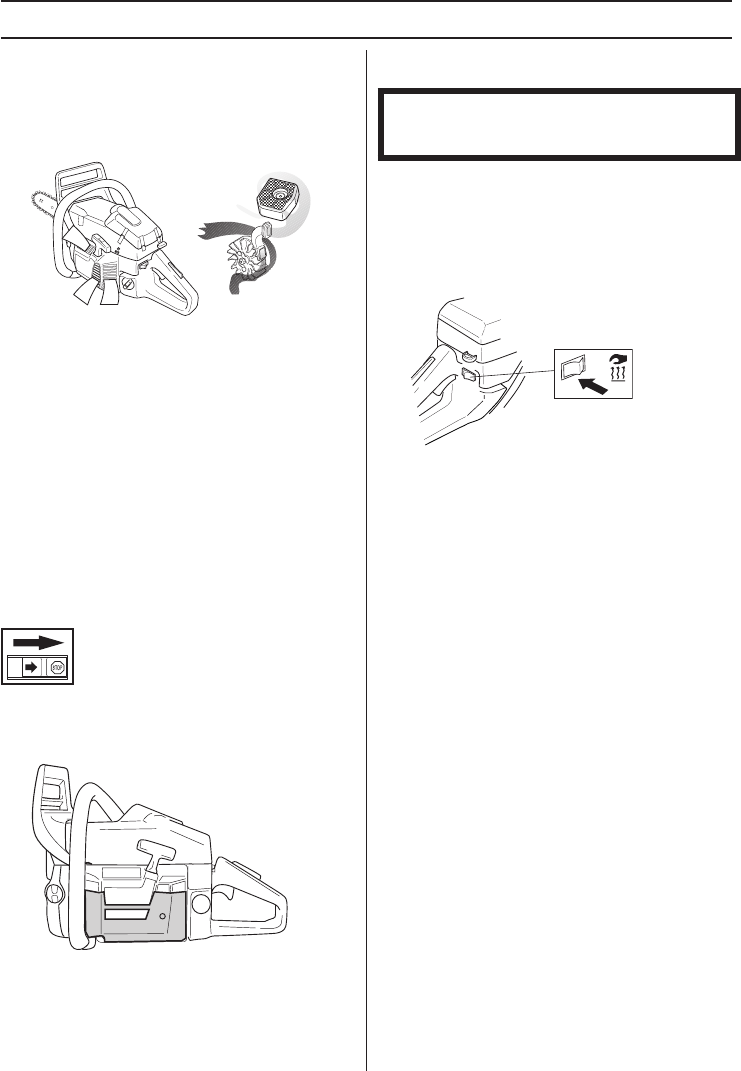

”Air Injection” centrifugal

cleaning

Centrifugal cleaning means the following: All air to the

carburettor passes through the starter. Dirt and dust is

centrifuged out by the cooling fan.

IMPORTANT! In order to maintain operation of the

centrifugal cleaning system it must be regularly

maintained. Clean the air intake to the starter, the fins on

the flywheel, the space around the flywheel, inlet pipe and

carburettor compartment.

Winter use

Running problems can occur when using the machine in

the cold and snowy conditions caused by:

• Too low engine temperature.

• Icing of the air filter and carburettor.

Special measures are therefore often required:

• Partly mask the air inlet on the starter to increase the

working temperature of the engine.

Temperature 0°C or colder:

For running the machine in cold weather or powder snow,

a special cover is available, which is mounted on the

starter housing. This reduces the intake of cold air and

prevents large amounts of snow from being sucked in.

CAUTION! If the special winterising kit has been fitted or

any measures have been taken to increase the

temperature these changes must be reversed before the

machine is used in normal temperature conditions.

Otherwise there is a risk of overheating, resulting in

severe damage to the engine.

Heated handles

(385XPG, 390XPG)

On models with the designation XPG/G, the front as well

as the rear handle are equipped with electric heating

coils. These are supplied with electricity from a built-in

generator on the chain saw.

Electrical carburettor heating

(385XPG)

On models with the designation XPG/G there is an

electrically heated carburettor. Electrically powered

heating prevents ice formation in the carburettor. A

thermostat regulates the heating so that the carburettor

always has the right working temperature.

IMPORTANT! Any maintenance other than that

described in this manual must be carried out by your

servicing dealer (retailer).