17

MAINTENANCE

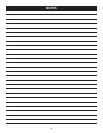

REMOVING THE WHEEL ASSEMBLY

See Figure 17.

To change the spark plug, you must remove the wheel.

To remove:

Remove the hitch pin from the axle.

Lift the machine and slide the axle/wheel combination

out of the machine base as shown.

NOTE: Reinstall the wheel when maintenance is complete

by reversing the above procedure.

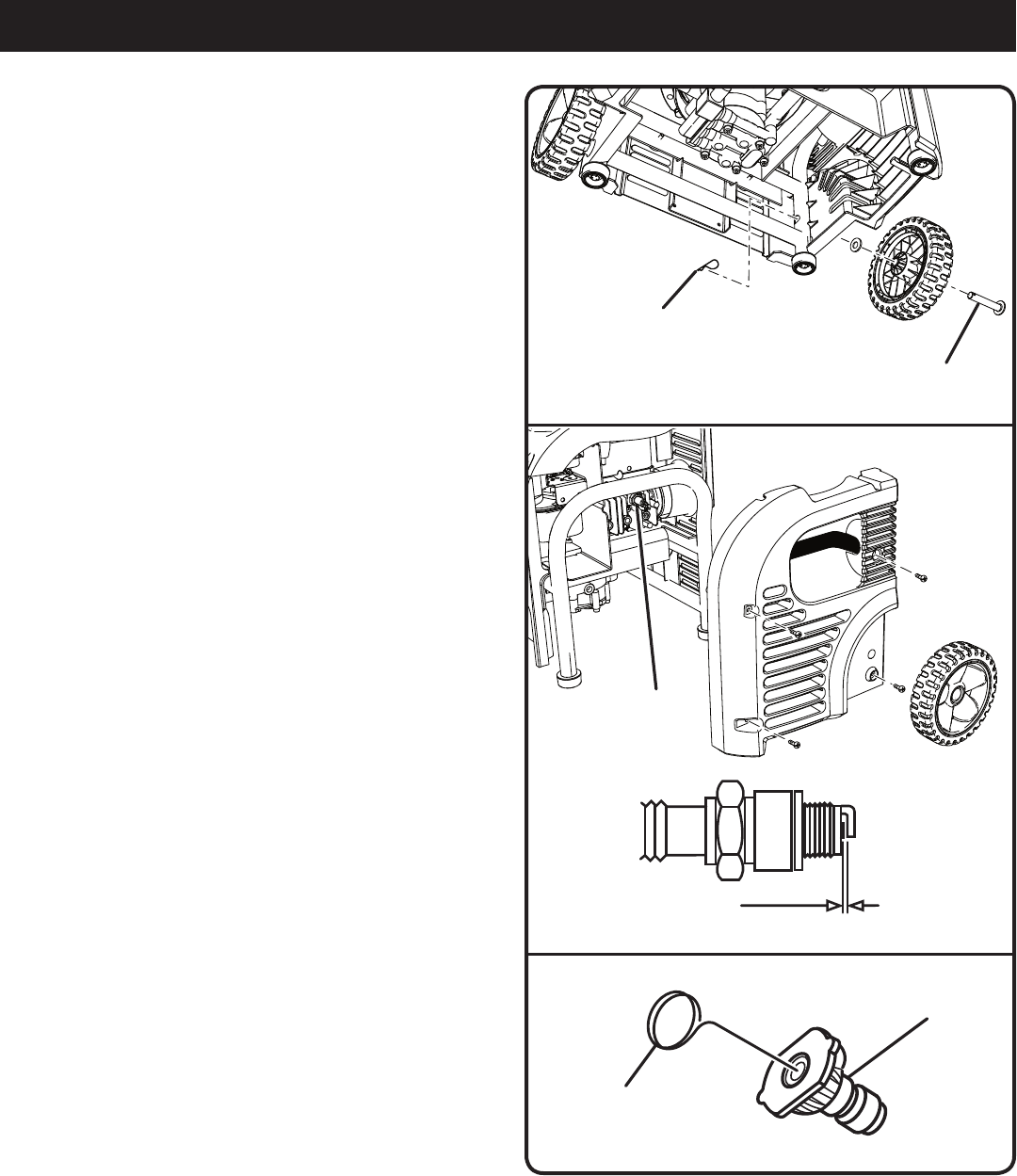

CHECKING A FOULED SPARK PLUG

See Figure 18.

Remove the wheel assembly as explained above.

Remove the screws holding the panel in place then lift

the panel away from the machine.

Clean carbon deposits off the spark plug electrode using

a plug cleaner or wire brush.

Check electrode gap. The gap should be .6 mm - .7 mm.

Adjust the gap, if necessary, by carefully bending the side

electrode.

(Recommended spark plug: NGK BR-6HS; CHAMPION

RL86C.)

NOZZLE MAINTENANCE

See Figure 19.

Excessive pump pressure (a pulsing sensation felt while

squeezing the trigger) may be the result of a clogged or

dirty nozzle.

�Turn off the pressure washer and shut off the water

supply. Pull trigger to release water pressure.

�Remove the nozzle from the spray wand.

NOTE: Never point the spray wand at your face.

�Using the nozzle cleaning tool provided, free any foreign

materials clogging or restricting the nozzle.

�Using a garden hose, flush debris out of nozzle by back

flushing (running the water through the nozzle backwards

or from the outside to the inside).

�Reconnect the nozzle to the spray wand.

�Turn on the water supply and start the engine.

Fig. 18

SPARK PLUG

0.6 - 0.7mm

Fig. 17

HITCH

PIN

AXLE

Fig. 19

NOZZLE

CLEANING TOOL

NOZZLE