OPERATOR MAINTENANCE

• Check gearbox oil level before first operation and every 200 hours of operation thereafter.

With frame level, remove oil plug on top side of gear box using 5/16” x 6” allen wrench

through access hole in frame. Use a piece of 1/16" dia. wire for checking fluid level. Push

wire into hole in gearbox until it hits the bottom. Pull out and measure the amount of oil

left on wire. There should be approx. 1-3/4" to 2" of oil on wire. If required, add 90w-

gear oil through plug in top of box until correct amount appears on wire. Replace top plug

securely.

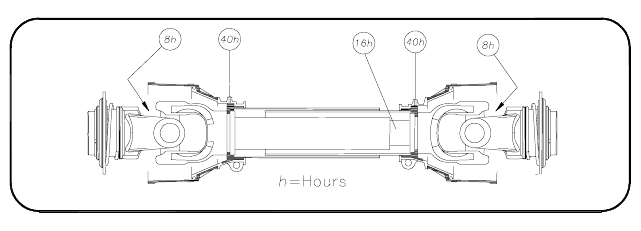

• Grease driveline parts after the number hours use as shown in the following chart.

Figure 5 Drive Line Lube Chart

• The hitch flex joints at the top of the “A” frame and above the gearbox (see page 18)

should be lubricated before first operation and weekly thereafter.

• After the first two hours of operation tighten all tines to 210-ft. lbs. Check for loose tines

daily.

• When replacing lost or worn tines use a 15/16” extra deep socket (Socket is available

through our repair parts. Order # AE60T003) and torque to 210 ft. lbs.

• CHECK BELT TENSION every 4 hrs. of operation for the first 12 hrs. and every 100

hrs. thereafter. Also, tighten belts if shaft hesitation is noticed during operation. Over

tightening belts may cause damage to the machine. Be sure to re-install belt shield after

servicing.

• Use the applicable parts break down illustration pp.16-22 for maintenance removal, and

assembly instructions.

• The AERA-vator shaft and rotor bearings are sealed and permanently lubricated requiring

no routine maintenance.

10