Remove spark plug wires and position wires away

from plugs.

Remove spark plugs.

Make sure the piston is at Top Dead Center (TDC)

of its compression stroke (both valves closed). To

get the piston at TDC, remove the intake screen at

the front of the engine to gain access to the flywheel

nut. Use a large socket and socket wrench to rotate

the nut and hence the engine in a clockwise direc-

tion. While watching the piston through the spark

plug hole. The piston should move up and down.

The piston is at TDC when it is at its highest point

of travel.

To adjust valve clearance (if necessary):

Make sure the engine is at 60° to 80° F.

Make sure that the spark plug wire is removed

from the spark plug and out of the way.

Remove the four screws attaching the valve cover

with a #2 or #3 Phillips screwdriver.

Loosen the rocker jam nut. Use an 10mm allen

wrench to turn the pivot ball stud while checking

clearance between the rocker arm and the valve

stem with a feeler gauge. Correct clearance is

0.002-0.004 inch (0.05-0.1 mm).

NOTE:

Hold the rocker arm jam nut in place as the pivot

ball stud is turned.

When valve clearance is correct, hold the pivot ball

stud in place with the allen wrench and tighten the

rocker arm jam nut. Tighten the jam nut to 174

in/lbs. torque. After tightening the jam nut, recheck

valve clearance to make sure it did not change.

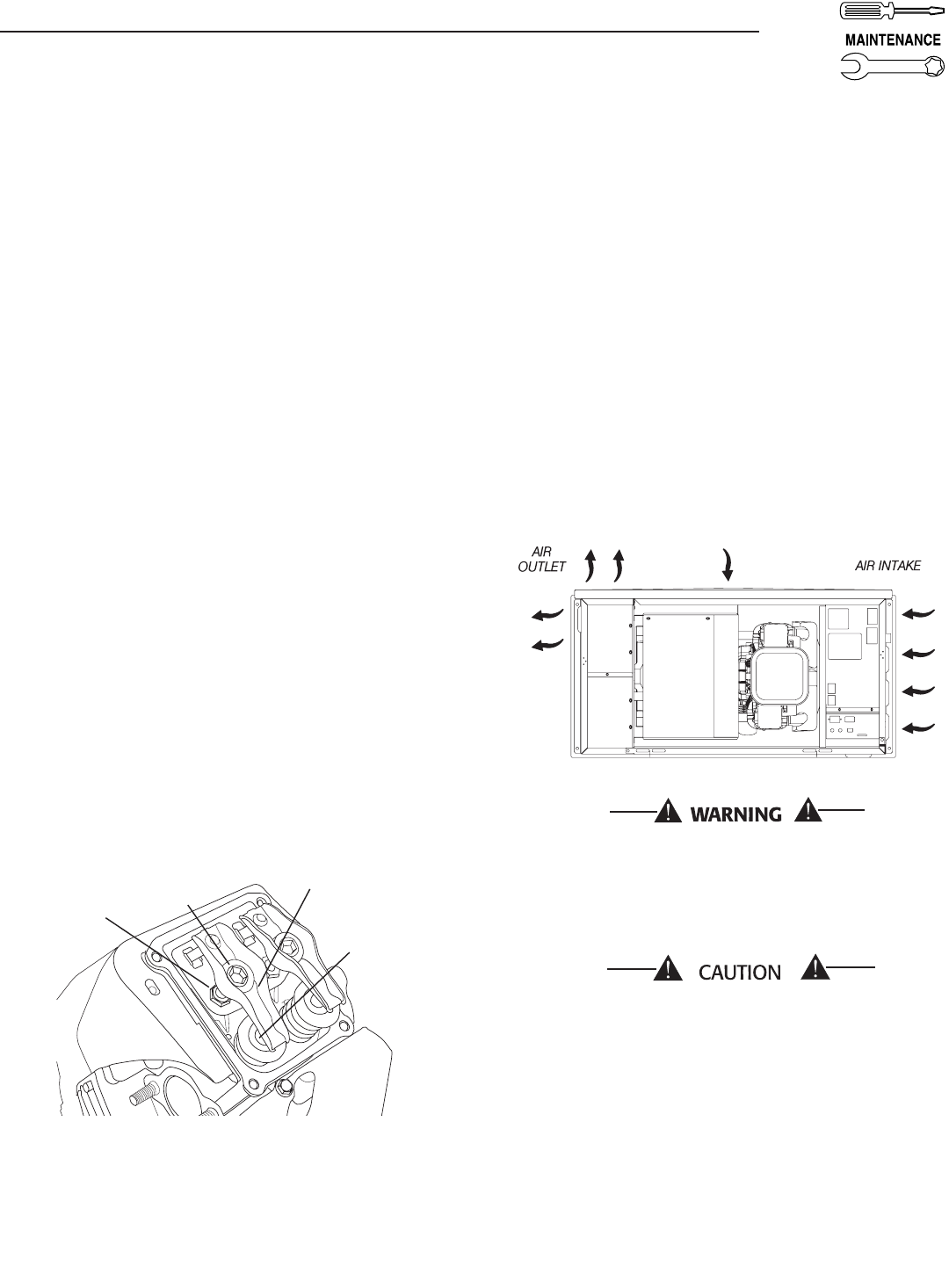

Figure 4.10 - Valve Clearance Adjustment

Jam Nut

Pivot Ball

Stud

Rocker

Arm

Valve

Stem

Install new valve cover gasket.

Re-attach the valve cover.

NOTE:

Start all four screws before tightening or it will not

be possible to get all the screws in place. Make

sure the valve cover gasket is in place.

•

•

•

•

•

•

•

•

•

Install spark plugs.

Re-attach the spark plug wire to the spark plug.

On the GT-530 and GT-990, repeat the process for

the other cylinder.

4.8 COOLING SYSTEM

Air inlet and outlet openings in the generator com-

partment must be open and unobstructed for con-

tinued proper operation. This includes such obstruc-

tions as high grass, weeds, brush, leaves and snow.

Without sufficient cooling and ventilating air flow, the

engine/generator quickly overheats, which causes it

to quickly shut down. (See Figure 4.11 for vent loca-

tions.)

Make sure the doors and roof are in place dur-

ing operation as running the generator with them

removed can effect cooling air movement.

Figure 4.11 – Cooling Vent Locations

The exhaust from this product gets extremely

hot and remains hot after shutdown. High grass,

weeds, brush, leaves, etc. must remain clear of

the exhaust. Such materials may ignite and burn

from the heat of the exhaust system.

The maximum ambient temperature for the gen-

erator is 40° C (104° F).

4.9 ATTENTION AFTER SUBMERSION

If the generator has been submerged in water, it must

not be started and operated. Following any submer-

sion in water, have an Authorized Dealer thoroughly

clean, dry and inspect the generator. If the structure

(ex. home) has been flooded, it should be inspected

by a certified electrician to ensure there won't be any

electrical problems during generator operation or

when utility is returned.

•

•

•

23

Section 4 — Maintenance

Air-cooled Generators