H8191 3600 PSI Diesel Pressure Washer

-11-

Break-In

The first 20 hours of operation is considered the

break-in period. Be sure to follow the maintenance

schedule on Page 16 after 20 hours of use.

NOTICE

Failure to follow the break-in maintenance

schedule can reduce the lifespan of

the machine and negatively impact

performance.

Adjusting Pressure

DO NOT attempt to increase the maximum

pump pressure by modifying controls or

otherwise altering the machine. A higher

pressure setting than the factory set

maximum pressure may damage the pump

or cause components to fail, resulting in

serious personal injury.

The pressure setting on the Model H8191 was

preset at the factory to achieve optimum pressure

for general purpose cleaning.

To adjust the pressure:

• BACK AWAY FROM THE SURFACE TO BE

CLEANED. Moving further away reduces the

pressure on the workpiece.

• SELECT A DIFFERENT NOZZLE. Nozzles

with a wider angled spray deliver a less

powerful stream.

• ADJUST THE PRESSURE REGULATOR

ON THE PUMP. Turn the water pressure

adjustment knob counterclockwise to lower

the pressure (

Figure 8). Once you have

finished using your pressure washer, return

the regulator to its original position by turning

it clockwise.

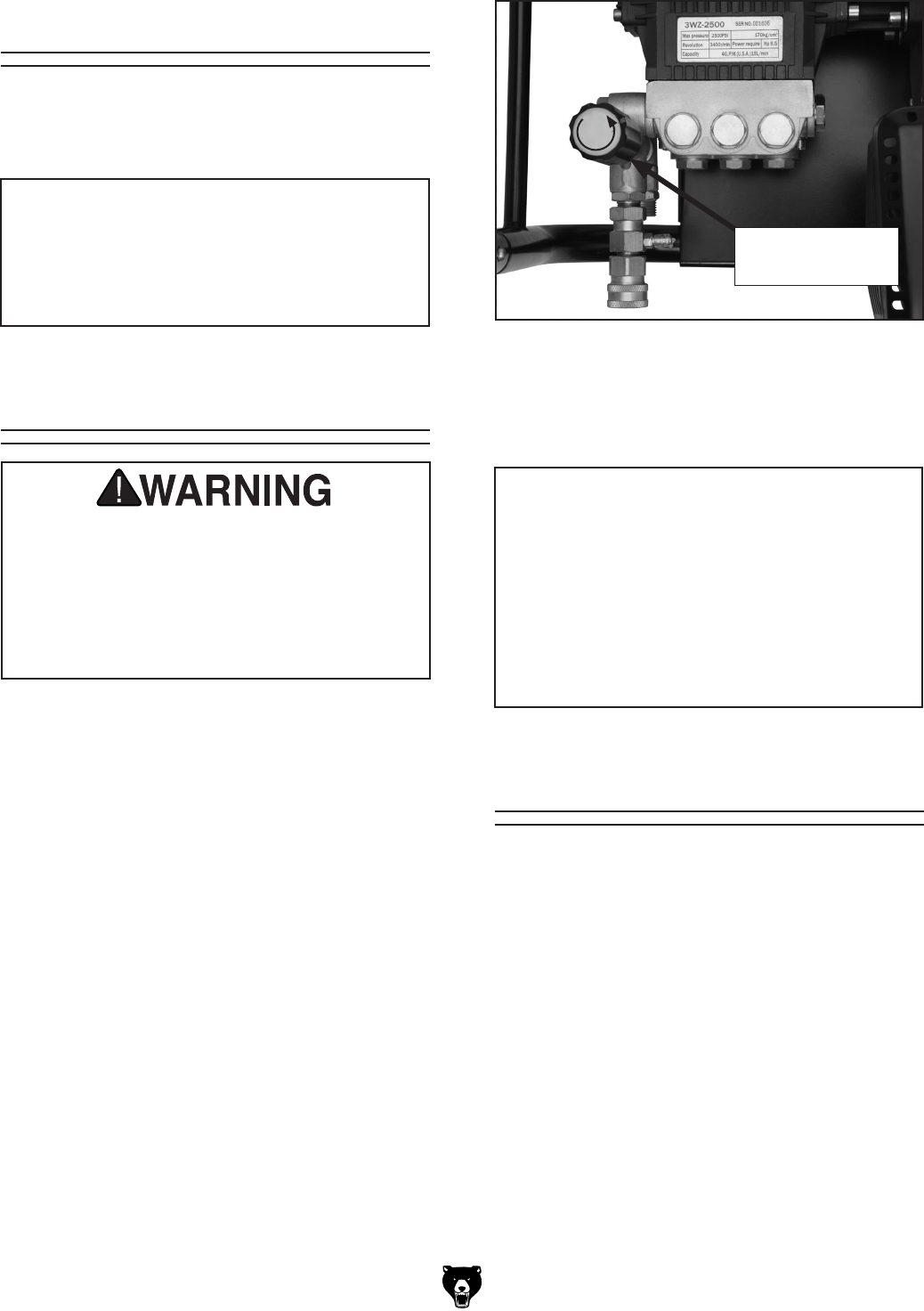

Figure 8. Water pressure adjustment knob.

• REDUCE ENGINE SPEED. Slowing the

engine will reduce the pressure created by

the pump.

NOTICE

Engine speed should always be set high

enough to handle the load of the pump. If

the engine speed is too low, the motor may

bog or stop when the spray gun trigger is

pulled and the pump is activated. Operating

the engine speed at such a setting can

cause excessive engine wear and premature

engine failure.

Changing Nozzles

The Model H8191 pressure washer is equipped

with five spray nozzles housed in receptacles on

the front panel. Each nozzle is color coded and

delivers a specific spray pattern for a particular

cleaning purpose. The 0°, 15°, 25°, and 40°

nozzles are high pressure nozzles; the chemical

nozzle is a low pressure nozzle.

Water Pressure

Adjustment Knob