Service Engine - 29

SERVICE ENGINE

MX15301

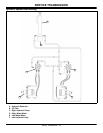

4. Disconnect fuel hose (A) from the outlet side of fuel filter

(B), and drain gasoline into a properly marked container.

5. Remove fuel filter from inlet fuel hose (C). Discard filter.

6. Connect a new fuel filter to hoses using new clamps.

Make sure fuel filter is installed with arrow pointing in

direction of fuel flow.

Priming Fuel Injectors - Fuel Injected Engines

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Allow engine to cool.

3. Fill fuel tank.

4. Turn key switch to run position and leave it in the run

position for 15 seconds.

5. Start the engine. If the engine will not start, repeat step

4 two times.

Troubleshooting the Kohler Electronic Fuel

Injection System

MX15334

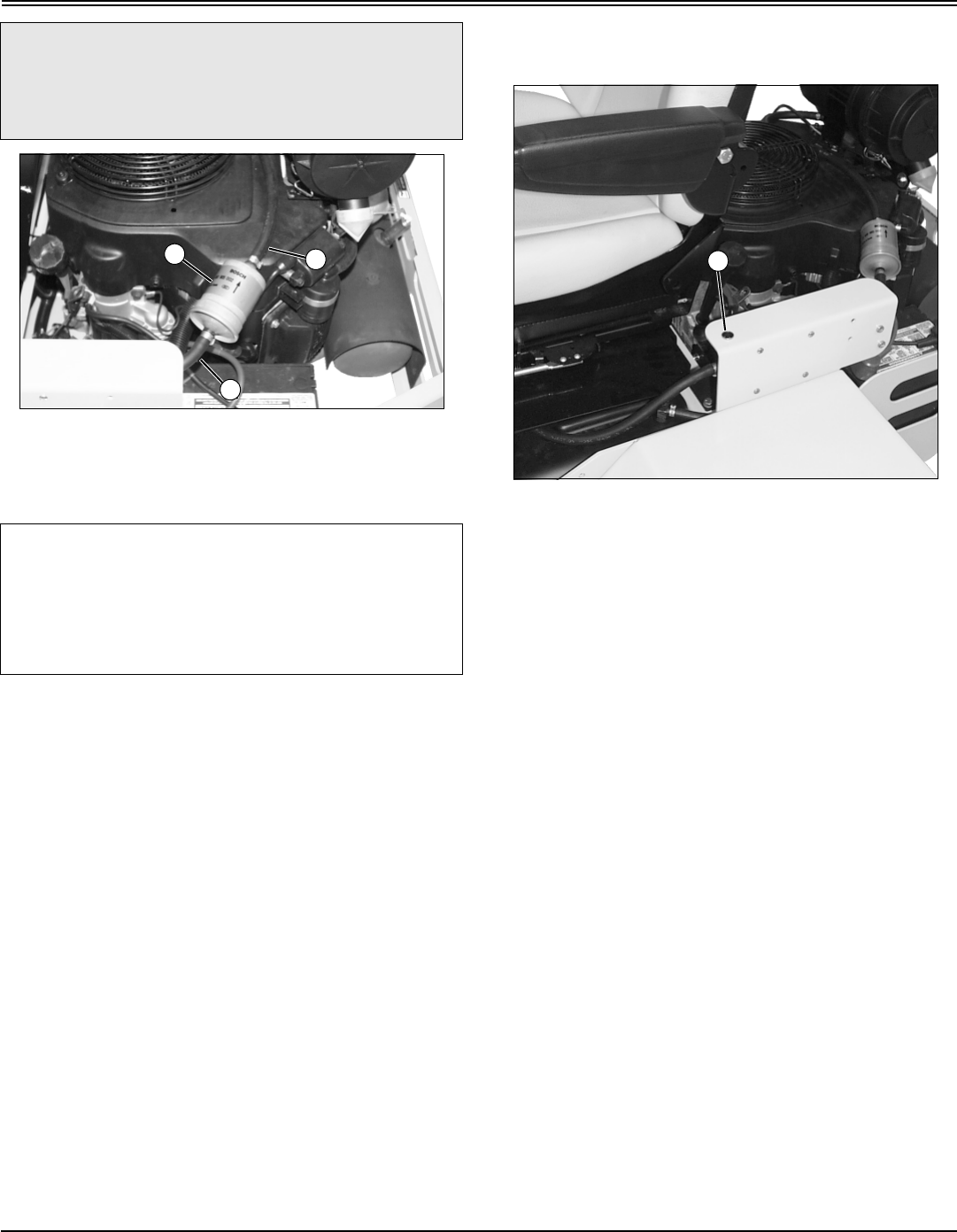

Chariot LX models equipped with Kohler engines with the

Electronic Fuel Injection (EFI) system will include an MIL

(Malfunction Indicator Light) (A). This light will indicate

potential problems with the EFI system.

The light will come on when the key switch is moved to the

run position, but should go out once the engine has started.

If the light remains on after the engine has started, or if the

engine fails to start, there may be a problem with the EFI

system or its related electrical system.

The MIL can also be used to access diagnostic codes to

aid service. These codes can be accessed only by an

authorized Kohler EFI servicing dealer.

When troubleshooting a problem with the Kohler EFI

system, basic engine operating problems must be

eliminated before faulting the EFI system components.

What appears to be an EFI problem could be something as

simple as a fuel tank with debris in the bottom or a plugged

vent. Be sure the engine is in good mechanical operating

condition and other systems are operating properly before

attempting to troubleshoot the EFI system.

The EFI system is a 12 VDC negative ground system,

designed to operate down to a minimum of 7.0 volts. If the

system voltage drops below this level, the operation of

voltage sensitive components such as the ECU, fuel pump

and injectors will be intermittent or disrupted, causing

erratic operation or hard starting. A fully charged, 12-volt

battery with a minimum of 250 cold cranking amps is

important in maintaining steady and reliable system

operation. Battery condition and state of charge should

always be checked first when troubleshooting an

operational problem.

c CAUTION: Avoid injury! Fuel system under

pressure. Wear personal eye protection when

disconnecting fuel hoses to guard against

spraying fuel.

IMPORTANT: Avoid damage! When installing a new

fuel filter, the filter arrow must be pointing in the

direction of fuel flow. Make sure clamps are installed

properly.

Use only approved replacement parts: fuel filter

(Bosch P/N D28256) and clamps (P/N D18439).

B

C

A

A