..

.

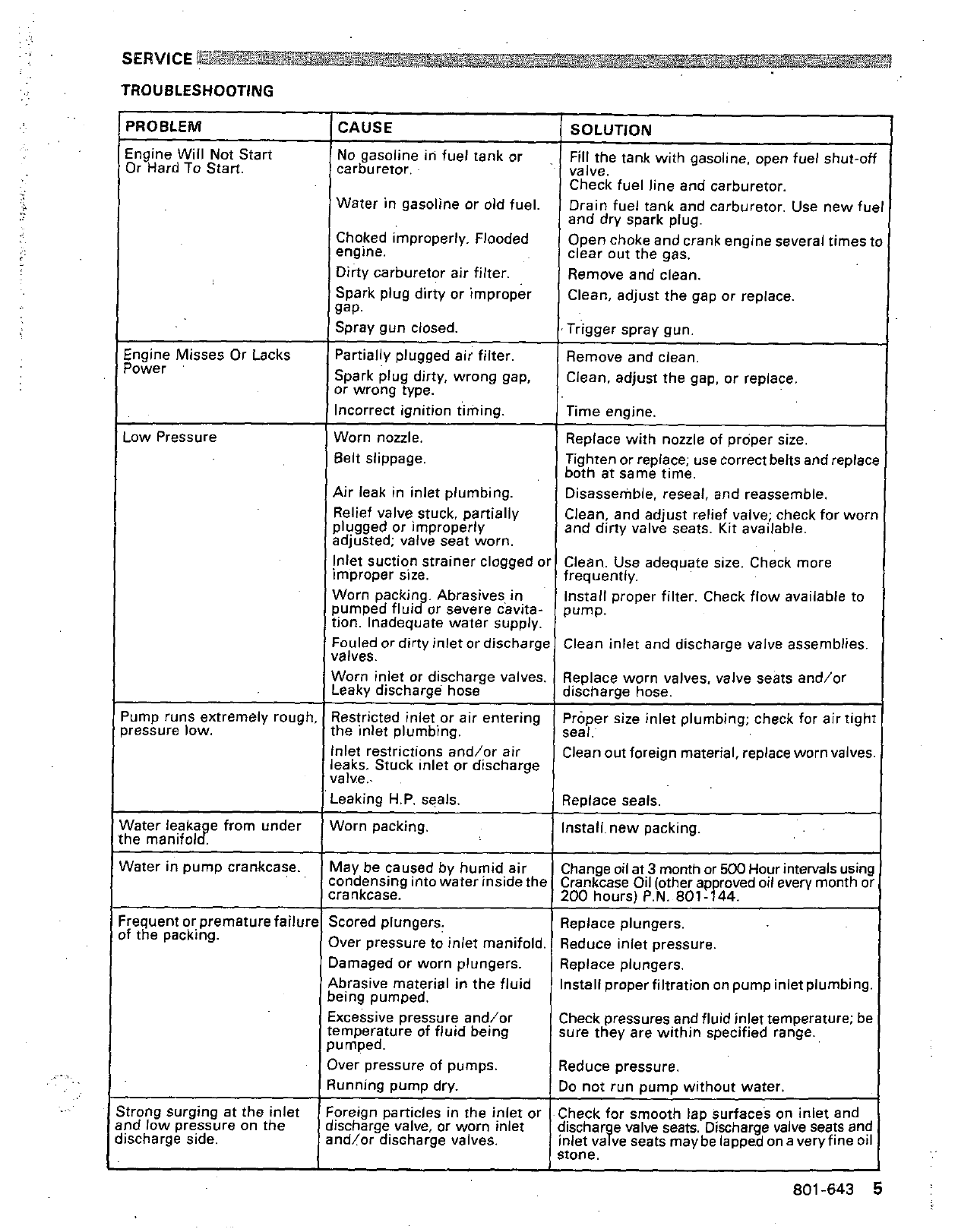

SERVICE

TROUBLESHOOTING

PROBLEM

~~

CAUSE

SOLUTION

valve.

Fill the tank with gasoline, open fuel shut-of

Check fuel line and carburetor.

Engine Will Not Start

Or Hard

To

Start.

No gasoline

in

fuel tank

or

carburetor,

Water

in

gasoline or old fuel.

Choked improperly. Flooded

engine.

Dirty carburetor air filter.

l

and dry spark plug.

Drain fuel tank and carburetor. Use new fu

Open choke and crank engine several times

clear out the gas.

Remove and clean.

Clean, adjust the gap or replace

Trigger spray gun

Spark plug dirty or improper

gap.

Spray gun closed.

ngine Misses Or Lacks

ower

Partially plugged air filter,

Remove and clean.

Clean. adjust the gap, or replace.

Spark plug dirty, wrong gap,

or wrong type.

Incorrect ignition timing.

Worn nozzle.

Belt slippage.

Air leak

in

inlet plumbing.

plugged or improperly

Relief valve stuck, partially

adjusted; valve seat worn.

Time engine.

I

ow Pressure

~~

Replace with nozzle of proper size

Tighten or replace; use correct belts and replac

both at same time.

Disassemble, reseal, and reassemble.

and dirty valve seats.

Kit

available.

Clean, and adjust relief valve; check for wor,

Clean. Use adequate size. Check more

frequently.

Install proper filter. Check flow available to

pump.

Clean inlet and discharge valve assemblies.

Replace worn valves, valve seats and/or

jischarge hose.

'roper size inlet plumbing; check for air tigh

seal:

:lean out foreign material, replace worn valves

Inlet suction strainer clogged or

improper size.

Worn packin Abrasives,

in

pumped fluidgbr severe cavita-

tion. Inadequate water supply.

Fouled or dirty inlet or discharge

valves.

Worn inlet or discharge valves.

Leakv discharae hose

lrmp runs extremely rough,

'essure low.

Restricted inlet or air entering

the inlet plumbing.

I

!

I

Replace seals

I

-

nlet restrictions and/or air

lalve..

eaks. Stuck inlet or discharge

-caking

H.P. seals.

Norn packing.

rater leaka e from under

e rnanifod

~ ~~ ~~~ ~~~

nstall. new packing.

Change oil at

3

month or

500

Hour intervals usin(

I

Crankcase Oil (other ap roved oil every month

01

?OO

hours) P.N.

801-r44.

later

in

pump crankcase.

May be caused by humid,air

:ondensing into water lnslde the

I

:rankcase.

equent orprematurefailurc

the packing.

Isplace plungers.

leduce inlet pressure

leplace plungers.

Scored plungers.

her pressure to inlet manifold.

lamaged or worn plungers.

ibrasive material

in

the fluid proper filtration

on

pump inlet plumbing

leing pumped.

Lxcessive pressure and/or

emperature of fluid being

Check pressures and fluid inlet temperature; be

lumped.

sure they are within specified range.

her pressure of pumps. Reduce pressure.

lunning pump dry. Do not run pump without water.

rong surging at the inlet

d low pressure on the

;charge side.

oreign particles

in

the inlet or

Check for smooth lap surfaces on inlet and

ischarge valve, or worn inlet

dischar e valve seats. Discharge valve seats and

nd/or discharge valves.

Inlet va

9

ve seats maybe 1appe.d on a veryflne

011

stone.

801-643

5