Operation

10 312585E

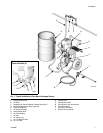

Starting the Pump

1. Open the bleed-type master air valve (A).

2. Trigger the gun into a grounded metal pail, holding a

metal part of the gun firmly to the pail.

3. Slowly open the air regulator (E) until the pump

starts running.

4. Run the pump slowly until all the air is purged,

release the gun trigger, and lock the trigger safety -

the pump will start and stop as the gun is opened

and closed.

Adjusting the Pump

• Always use the lowest pressure necessary to get

the desired results.

• Never allow the pump to run dry of fluid being

pumped. A dry pump will quickly accelerate to a

high speed, possibly damaging itself. If your pump

accelerates quickly, or is running too fast, stop it

immediately and check the fluid supply. If the supply

container is empty and air has been pumped into

lines, prime the pump and lines with fluid, or flush

and leave filled with a compatible solvent. Be sure to

eliminate all air from the fluid system.

• The piston and intake check valves of displacement

pump 247599 are factory-set for light viscosity flu-

ids. This setting minimizes surging at pump stroke

changeover. To adjust the valves for heavier viscos-

ity fluids, see manual 312745.

• Always stop the pump at the bottom of its stroke to

prevent fluid from drying on the rod and damaging

the throat packings. When you finish pumping,

always relieve the pressure, page 9.

• If you are pumping fluid which dries, hardens, or

sets up, flush the system with a compatible solvent

as often as necessary to prevent a build up of dried

fluid in the pump or hoses.

• Every 40 hours of operation, check that the packing

nut is tight. Relieve the pressure, page 9. Then,

tighten the packing nut just snug - do not overtighten

or the packings may be damaged.