Installation

6 3A2573D

Installation

1. Connect the mixed material supply line from the pro-

portioner or 1K sprayer to the manifold material inlet

port (D).

2. Connect a hose between each manifold gun mate-

rial outlet (G,H) and spray gun fluid inlet.

3. Connect a solvent supply hose from the solvent sup-

ply to the manifold solvent inlet port (C).

Operation

Depending on which gun you want to supply material to,

open the material shutoff valve for gun #1 (A), gun #2

(F), or both valves.

To shut off material supply to a gun, close the material

shutoff valve (A or F).

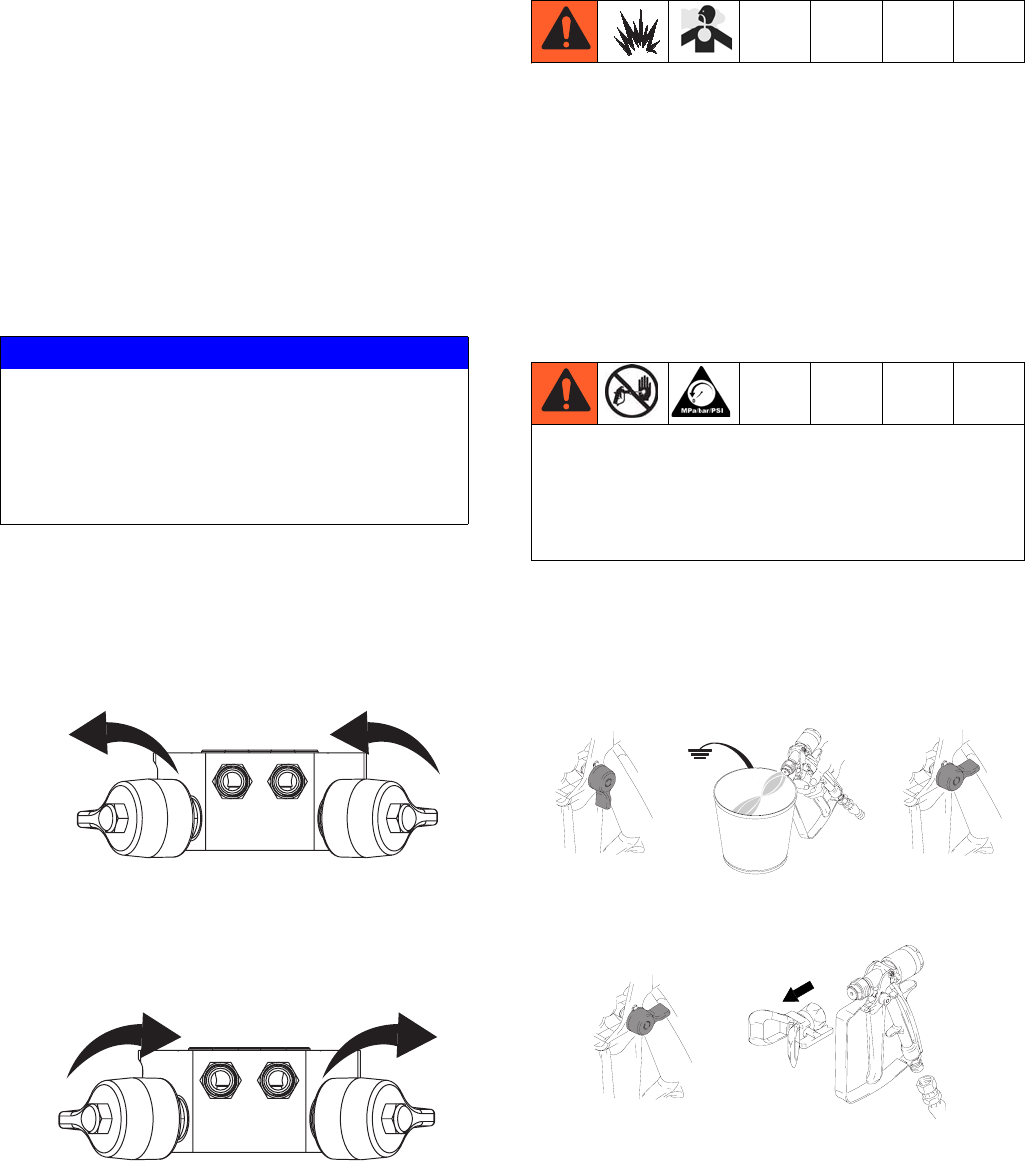

Flushing

The gun splitter valve can flush both guns at the same

time or flush one gun independently while the other gun

continues to spray. The equipment must be flushed if:

• Any gun will not be used within the pot life of the

material.

• Neither gun will be used within the pot life of the

material. The mixed feed line, splitter, and both guns

must be flushed.

1. Close the material shutoff valves gun #1 (A) or gun

#2 (F) for the gun to be flushed.

2. Relieve material pressure in the gun to be flushed

by unlocking the trigger lock. Trigger the gun into a

grounded pail. Lock trigger lock.

3. Lock trigger lock. Remove spray tip.

4. Turn on solvent supply and set the pressure as

needed for flushing.

NOTICE

Do not allow mixed material to reside in equipment

longer than the pot life of the material at fluid tem-

perature. Pot life is much shorter than dry time.

Heated material cures much faster than ambient

and may damage your equipment. Check your

material safety data sheet (MSDS).

A - OPEN F - OPEN

A - CLOSE

F - CLOSE

To reduce the risk of skin injection, follow the

Pressure Relief Procedure in your proportioner or 1K

sprayer manual when you stop spraying and before

cleaning, checking, servicing, or transporting

equipment.

Locked

Unlocked

TI1948A

Locked