Repair

10 3A0540L

8. Remove the wet-cup (34) and o-ring (52). Remove

the TSL pump piston seal (36), spring (35), and

o-rings (51).

9. Remove the throat cartridge (27). Remove the

o-ring (52), glands (32, 33), packings (30, 31), and

spring (28).

10. Remove the nuts (12), lockwashers (11), and six

cylinder capscrews (10). Lift off the outlet valve

housing (2).

11. Lift the riser tubes (6) and cylinder (4) off the inlet

valve housing (7). The piston assembly may stay in

the cylinder. Remove the seals (3 and 5) from the

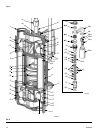

inlet and outlet housings (2, 7). See F

IG

. 5.

NOTE: Tap on the valve housings with a plastic mallet

and use a slight rocking motion to help loosen and

remove the cylinder and tubes.

12. If Part No. 218742 accessory pump stand is used,

unscrew and remove the three pump stand bolts.

Lift the inlet valve assembly off the stand. Place the

inlet valve housing (7) face down on a protected

surface.

13. Use a 13 mm socket wrench to loosen and remove

the twelve capscrews (9) and lockwashers (8) from

the inlet manifold (1). See F

IG

. 5.

14. Lift the manifold (1) off the inlet valve housing (7)

and remove the seats (13 and 14). Remove the

o-ring (15) from the seats. Remove the balls (18),

ball guides (16) and seals (17).

15. Inspect the pressure relief valve in the fluid inlet

seat (14) to make sure it is not clogged. Press down

on the valve's ball to see if the ball and spring are

free to move. See F

IG

. 4.

16. Push the piston assembly through the cylinder just

enough to expose the piston (26) flats. Secure the

piston flats in a vise. Use a plastic mallet to tap the

cylinder (4) up and off the piston assembly.

17. Loosen the piston nut (21). Use Tool Kit 220385 (to

remove the piston shaft (19) and piston nut (21).

Remove the piston nut o-ring (22) and o-ring

retainer (20) from the shaft. Remove the plate (24)

and the seal (25) from the piston (26).

18. Inspect the piston shaft (19). If it is damaged or the

surface is scored, replace it.

19. Clean all piston parts and the cylinder thoroughly in

a compatible solvent. Inspect the inner surface of

the cylinder for scoring, and replace it if necessary.

A scored cylinder will quickly damage the packings.

NOTICE

Be careful not to drop or damage the balls (18) or

seats (13 or 14). A damaged ball or seat cannot seal

properly and the pump will leak. One inlet valve seat

(13) can be reversed to provide longer use of the seat.

However, the fluid inlet seat (14) contains a pressure

relief valve and is not reversible. See F

IG

. 5 for proper

orientation.

F

IG

. 4. Inlet Seat with Pressure Relief Valve

NOTICE

If the pressure relief valve in the inlet seat (14) is

clogged or filled with material, soak the seat in a com-

patible solvent. Make sure all material residue is

cleaned from the ball and seat area.

If the relief valve cannot be thoroughly cleaned so that

the ball and spring are free to move, replace the seat

(14).

TI15631a

15

14

ball

spring

pressure relief valve