15

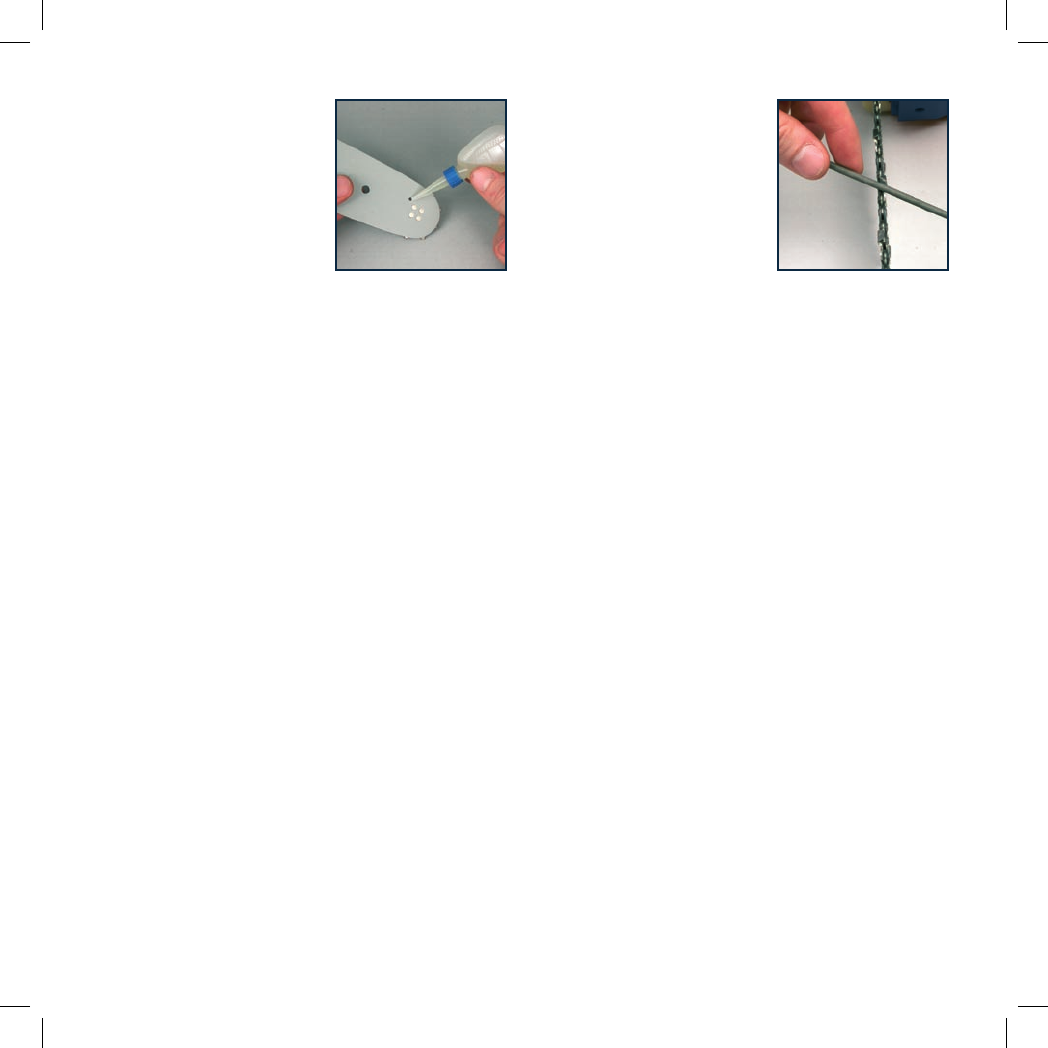

6. Make sure that the oil port is

not clogged. Grease the nose

sprocket at the tip of the

guide bar.

7. Check for fuel and oil leakage

and loose fastenings,

especially those securing the

handles and the guide bar. If

any defects are found, take

the tool to an authorised

repair centre.

8. Clean any dust away from the cooling vents as clogged

vents can cause overheating.

Chain sharpening

Sharpen the chain regularly to maintain optimum

performance of the saw. Signs of a dull chain are:

• The sawdust becomes powder-like

• Extra force is required to execute a cut

• The cut does not track in a straight line

• Increased vibration

• Increased fuel consumption

WARNING. Wear heavy

gloves when handling the chain.

Hold the guide bar (1) securely

in a vice.

Sharpen each cutter using a

chain file. Always use outward

strokes.

After sharpening, the cutters

must all have the same width and length. After every 3-4

times use an authourised repair centre to professionally

sharpen your saw chain. They have the special tools

necessary to ensure the correct cutting angles and depths.

Guide bar wear

Reverse the guide bar every 8 working hours to ensure

uniform wear. Check the bar rails frequently and if

necessary remove burs and square-up the rails using

a flat file.