20

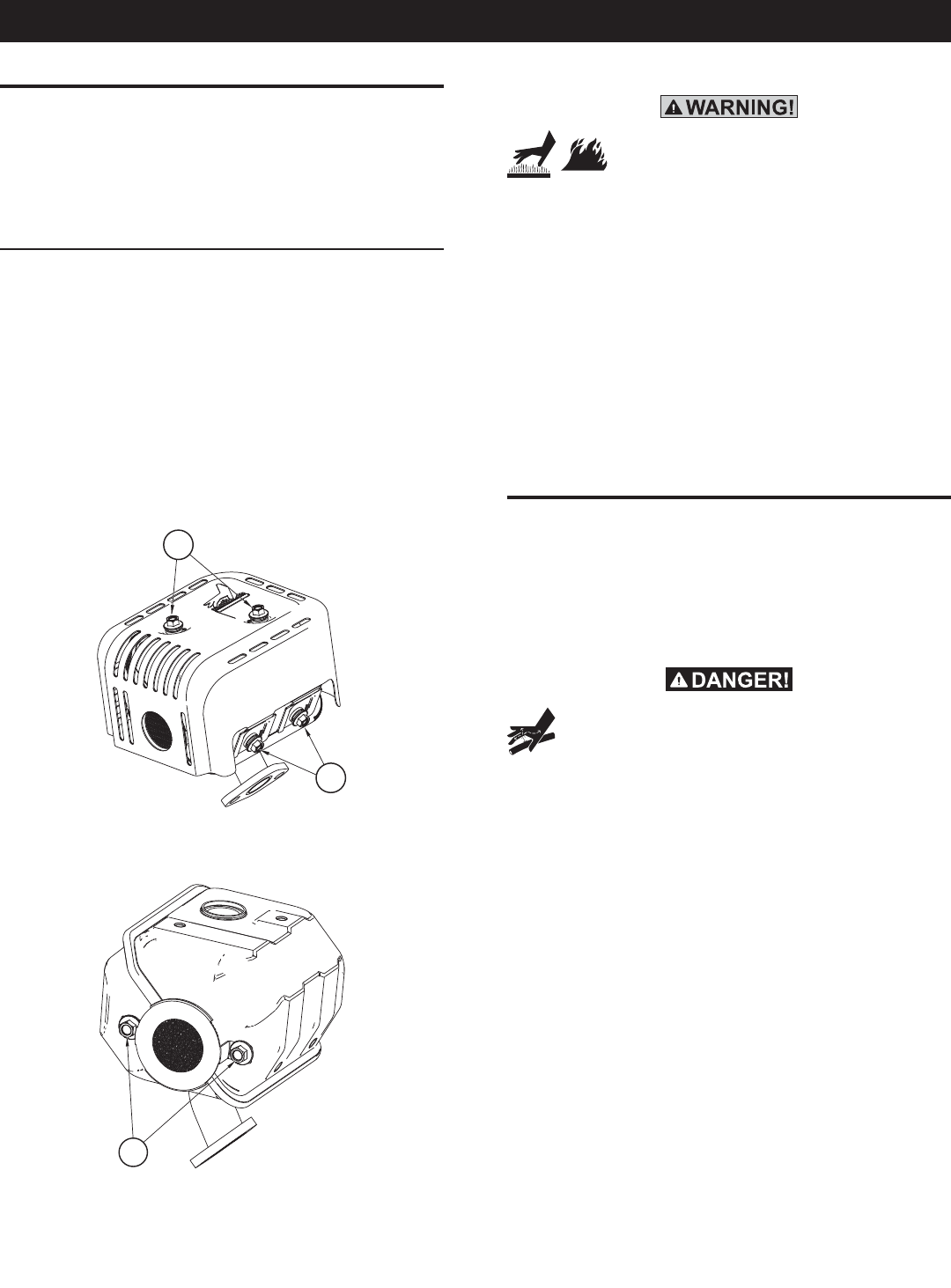

INSPECT MUFFLER AND SPARK ARRESTER

Inspect the muffler for cracks, corrosion, or other damage.

Remove the spark arrester, if equipped, and inspect for damage or

carbon blockage. If replacement parts are required, make sure to

use only original equipment replacement parts.

REMOVE SPARK ARRESTER SCREEN

Tools Required: 8mm Box Wrench

1. Remove heat shield from the muffler by loosening the four (4)

Bolts (A) (Figure 43).

2. Remove the spark arrester from the muffler by loosning the

two (2) Bolts (B) (Figure 44).

3. Inspect the spark arrester, replace if torn, perforated or

otherwise damaged (part number 0K1851). DO NOT USE A

DEFECTIVE SCREEN.

4. If screen is not damaged, clean it with a commercial solvent

and replace.

Figure 43 – Remove Heat Shield

A

A

Figure 44 – Remove Spark Arrester

B

Contact with muffler area can result in serious

burns. Exhaust heat/gases can ignite

combustibles, structures or damage fuel tank

causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (152 cm) of clearance on all sides of power

washer including overhead.

• It is a violation of California Public Resource Code, Section 4442,

to use or operate the engine on any forest-covered, brush-covered,

or grass-covered land unless the exhaust system is equipped with

a spark arrester, as defined in Section 4442, maintained in effective

working order. Other states or federal jurisdictions may have similar

laws.

Contact the original equipment manufacturer, retailer, or dealer to

obtain a spark arrester designed for the exhaust system installed

on this engine.

• Replacement parts must be the same and installed in the same

position as the original parts.

AFTER EACH USE

Water should not remain in the unit for long periods of time.

Sediments or minerals can deposit on pump parts and freeze pump

action. Follow these procedures after every use:

1. Shut off engine, turn off water supply, point gun in a safe

direction, and squeeze trigger to relieve trapped pressure, and

let engine cool.

The high pressure stream of water that this equipment

produces can cut through skin and its underlying

tissues, leading to serious injury and possible

amputation. Spray gun traps high water pressure, even

when engine is stopped and water is disconnected,

which can cause injury.

• Keep high pressure hose connected to pump and spray gun while

system is pressurized.

• ALWAYS point spray gun in safe direction and squeeze spray

gun trigger, to release high pressure, every time you stop engine.

Engage trigger lock when not in use.

2. Disconnect hoses from spray gun and high pressure outlet on

pump. Drain water from hoses, spray gun, and lance. Use a

rag to wipe off the hose.

3. Empty pump of all pumped liquids. Check that the engine ON/

OFF switch and fuel valve are in the OFF position. Then pull the

recoil handle about six times. This should remove most liquid

in pump.

4. Store unit in a clean, dry area.

5. If storing for more than 30 days, see the Long Term Storage

section.

Maintenance