23

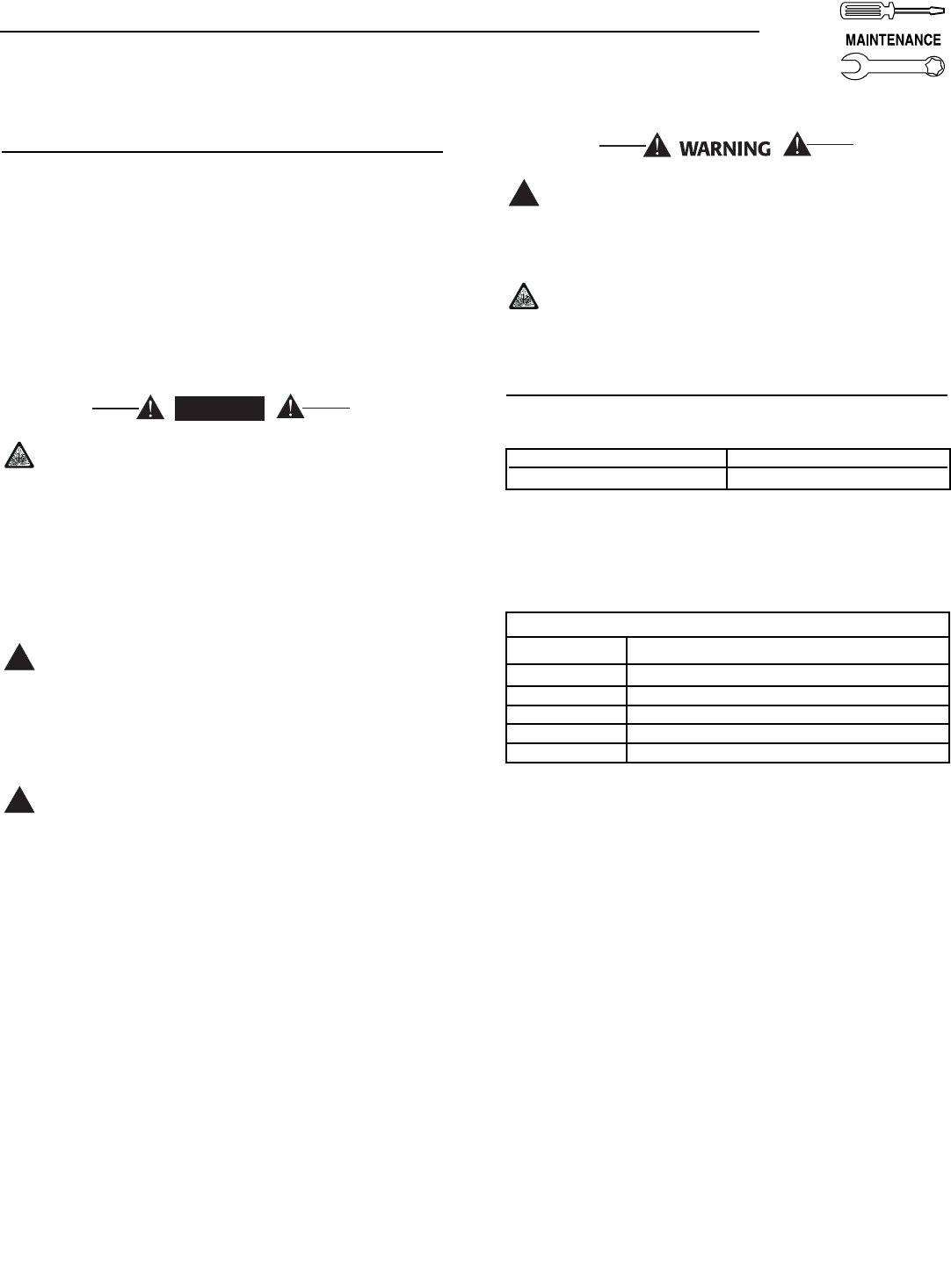

4.9.3 BATTERY MAINTENANCE

The battery should be inspected per Section 4.7,

Scheduled Maintenance. The following procedure

should be followed for inspection:

1. Inspect the battery posts and cables for tightness

and corrosion. Tighten and clean as necessary.

2. Check the battery fluid level of unsealed batteries

and, if necessary, fill with DISTILLED WATER

ONLY. Do not use tap water in batteries.

3. Have the state of charge and condition checked.

This should be done with an automotive-type bat-

tery hydrometer.

Storage batteries give off explosive hydrogen

gas. This gas can form an explosive mixture

around the battery for several hours after

charging. The slightest spark can ignite the gas

and cause an explosion. Such an explosion can

shatter the battery and cause blindness or

other injury. Any area that houses a storage

battery must be properly ventilated. Do not

allow smoking, open flame, sparks or any spark

producing tools or equipment near the battery.

Battery electrolyte fluid is an extremely corro-

sive sulfuric acid solution that can cause severe

burns. Do not permit fluid to contact eyes, skin,

clothing, painted surfaces, etc. Wear protective

goggles, protective clothing and gloves when

handling a battery. If fluid is spilled, flush the

affected area immediately with clear water.

Do not use any jumper cables or booster bat-

tery to crank and start the generator engine. If

the battery has completely discharged, remove

it from the generator for recharging.

Be sure the AUTO/OFF/MANUAL switch is set to

the OFF position, before connecting the battery

cables. If the switch is set to AUTO or MANUAL,

the generator can crank and start as soon as

the battery cables are connected.

Be sure the utility power supply to the battery

charger is turned off, or sparking may occur at

the battery posts as the cables are attached

and cause an explosion.

4.9.4 BATTERY REPLACEMENT

When replacing batteries, use the same number and

the type of battery that follows:

NOTE:

The BCI number should be located directly

on the battery.

!

!

!

DANGER

Section 4 — Maintenance

Liquid-cooled 15, 20 and 25 kW Generators

BCI Group No. CCA

26-60R 525 @ 0 deg. F

PERIODIC REPLACEMENT PARTS

Part Name Part Number

Oil Filter Motorcraft FL-400-S (supplied with engine)

Radiator Cap # 046627

Air Cleaner # 059402

Spark Plug Motorcraft AWSF-52-C (supplied with engine)

Battery # 077483