Not for

Reproduction

44 www.ferrisindustries.com

B

C

A

B

B

B

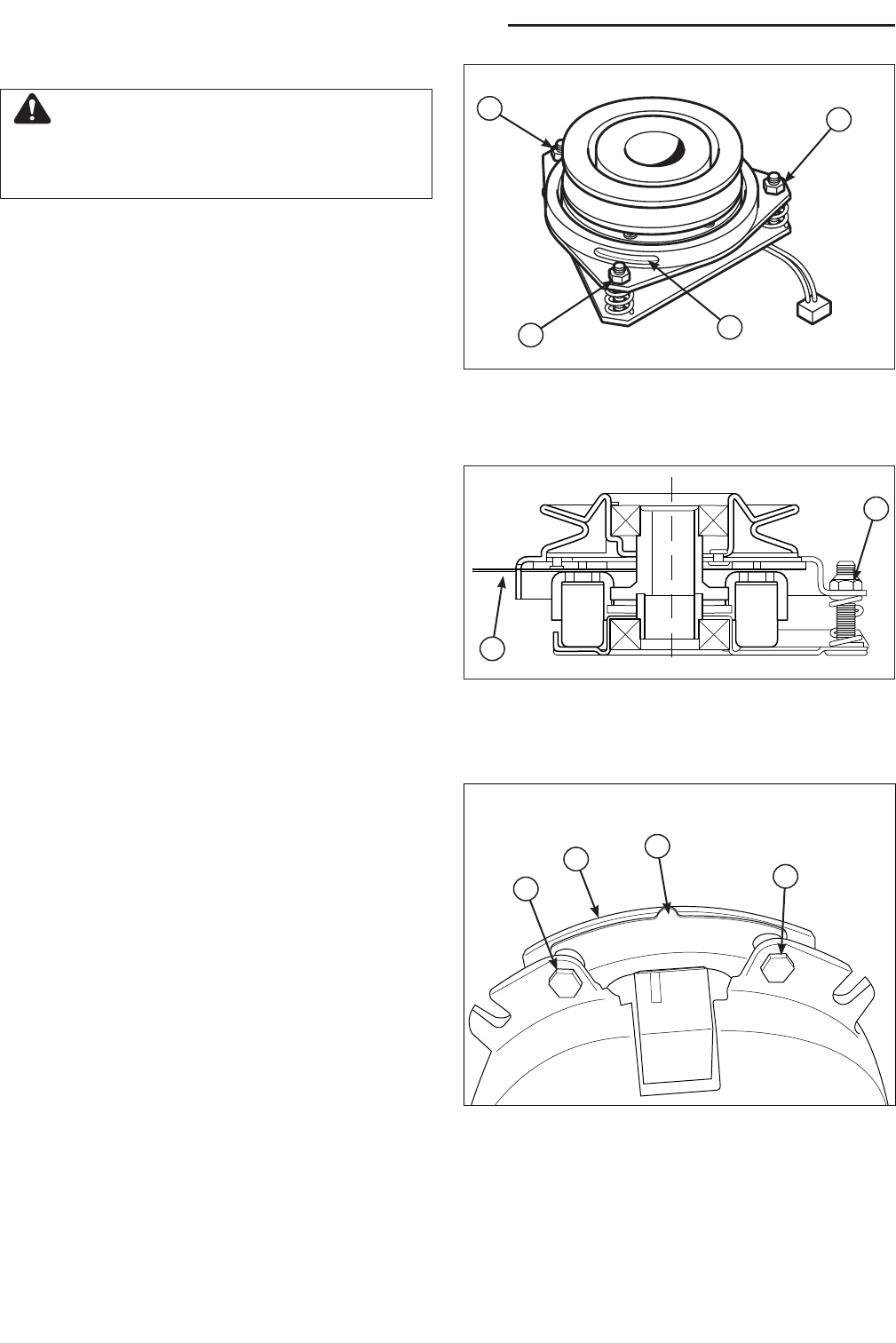

Figure 49. PTO Clutch Adjustment

A. Adjustment Window (Qty. 3, one shown)

B. Adjustment Nut

Figure 50. Adjust PTO Clutch

A. Window

B. Adjustment Nut

C. .016”-.018” (0,40-0,45mm) Feeler Gauge

PTO Clutch Adjustment

All other Models: S/N: All

Briggs & Stratton 543777-0120-E1 Models: S/N:

2013556397 & Above:

Check the PTO clutch adjustment after the initial 25

hour break-in period and then after every 100 hours

of operation. Also perform the following procedure

if the clutch is slipping or will not engage, or if a new

clutch has been installed.

1. Remove key from ignition switch and disconnect

spark plug wires to prevent the possibility of

accidental starting while the PTO is being

adjusted.

2. See Figure 49. Note the position of the 3

adjustment windows (A) in the side of the brake

plate and the nylock adjustment nuts (B).

3. Insert a .016”-.018” (0,40-0,45mm) feeler gauge

(C) through each window, positioning the gauge

between the rotor face and the armature face as

shown in Figure 50.

4. Alternately tighten the adjustment nuts (B, Figure

50) until the rotor face and armature face just

contacts the gauge.

5. Check the windows for an equal amount of drag

when the gauge is inserted and removed, and

make any necessary adjustments by tightening or

loosening the adjustment nuts.

NOTE: The actual air gap between the rotor and

armature may vary even after performing the

adjustment procedure. This is due to dimensional

variations on component parts, and is an acceptable

condition.

6. Check the mower blade stopping time. See

BLADE BRAKE CHECK. The mower blades and

mower drive belt should come to a complete stop

within seven (7) seconds after the electric PTO

switch is turned off.

Briggs & Stratton 543777-0120-E1 Models: S/N:

2013556397 & Above:

If the clutch is slipping or the clutch will not engage,

the air gap can be adjusted by removing the re-gap

shim to allow the clutch to continue to function.

1.

Loosen both brake mounting bolts (A, Figure 51)

1/2 to 1 full turn as shown in Figure 51.

IMPORTANT NOTE: Do not remove the brake pole

(B, Figure 51) from the clutch. The brake pole must

remain in the correct position to ensure proper brake

torque.

WARNING

To avoid serious injury, perform adjustments

only with engine stopped, key removed and

tractor on level ground.

A

A

C

B

Figure 51. PTO Clutch Adjustment

A. Brake Mounting Bolts

B. Brake Pole

C. Re-gap Shim

Troubleshooting, Adjustment & Service