Maintenance

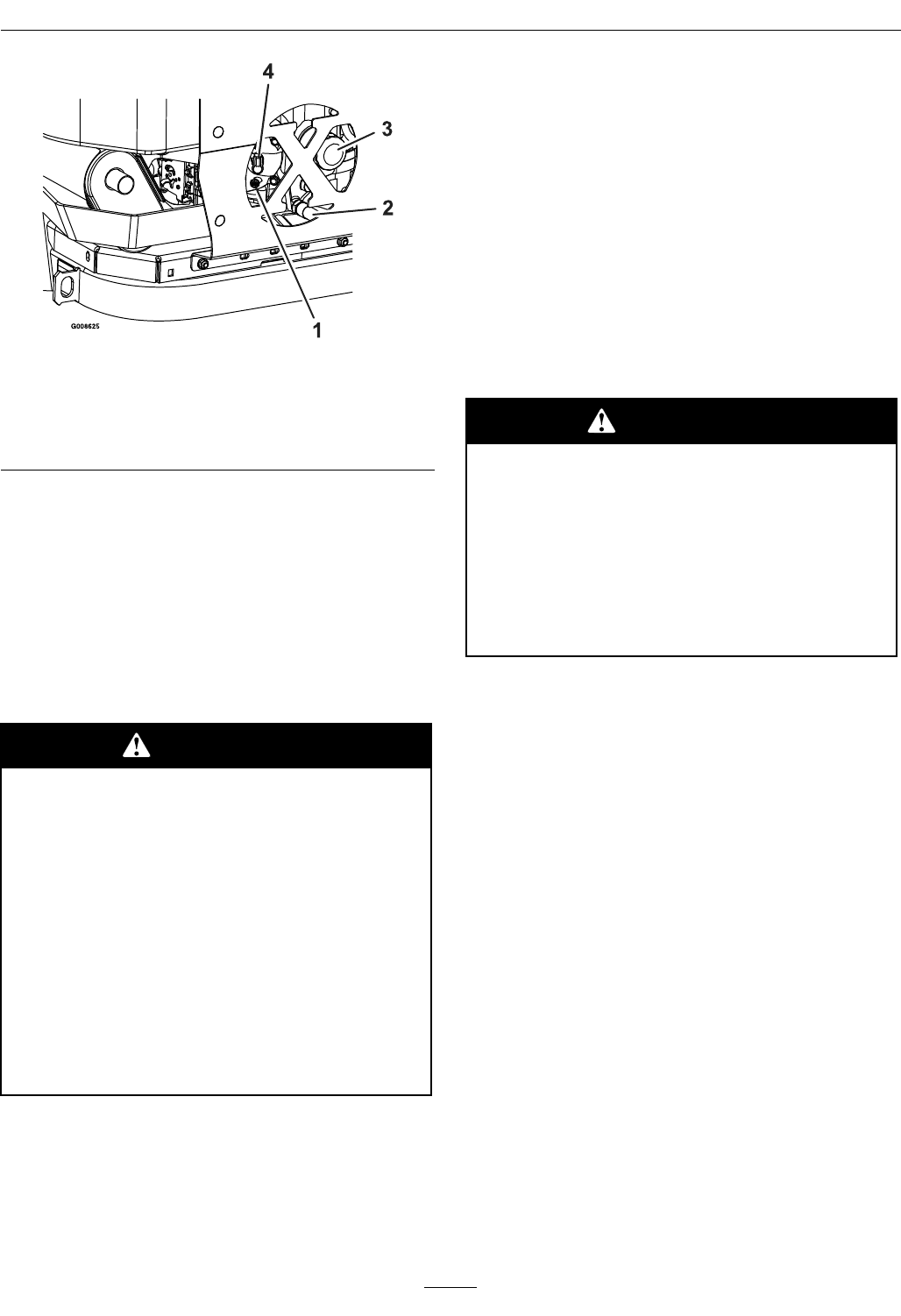

Figure 28

1. Coolant drain plug (black head)

2. Oil drain hose

3. Oil lter

4. Spark plug

4. Rotate the drain plug clockwise and remove pan.

5. Fill radiator with a 50/50 mix of water and

Dex-Cool© coolant as specied in the Check

Engine Coolant Level section, allowing some

room (approximately 1/2 inch (12.7 mm)) for

expansion. Add 50/50 coolant mix to overow

bottle on the right side of the engine as required

to bring the level up to the indicator line on the

bottle.

WARNING

Engine compartment contains open belt

drives, fans, and other rotating components

that can cause injury. Fingers, hands, loose

clothing, or jewelry can get caught by the

rotating fan and drive shaft.

• Do Not operate machine without the

covers in place.

• Keep ngers, hands, and clothing clear of

rotating components.

• Shut off engine, wait for moving parts to

stop, engage parking brake and remove

key, before performing maintenance.

6. With the cap off the radiator, start the engine as

stated in the Operating Instructions Section.

7. Operate engine until the engine thermostat opens

and coolant is circulating through the radiator

core. As air is purged from the engine block and

the coolant level drops, add additional coolant to

the radiator.

8. When the radiator is completely full and no

additional coolant can be added, continue running

and install the radiator cap. Make sure that the

cap is completely seated by pressing down rmly

while turning until the cap stops. Once the cap is

installed, the engine may be stopped.

Check Spark Arrester

(if equipped)

Service Interval: Every 50 hours

WARNING

Hot exhaust system components may ignite

gasoline vapors even after the engine is

stopped. Hot particles exhausted during

engine operation may ignite ammable

materials. Fire may result in personal injury

or property damage.

Do Not refuel or run engine unless spark

arrester is installed.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Wait for mufer to cool.

3. If any breaks in the screen or welds are observed,

replace arrester.

4. If plugging of the screen is observed, remove

arrester and shake loose particles out of the

arrester and clean screen with a wire brush (soak

in solvent if necessary). Reinstall arrester on

exhaust outlet.

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242”

or “Fel-Pro, Pro-Lock Nut Type” are used on the

following fasteners:

• ROPS spring pin housing.

• Hydro pump control arm, linkage bolt, and

attachment bolt.

• Hydro cooling fan screw.

• Hydro park brake cable anchor mounting bolt

• Sheave and clutch retaining bolt in the end of

engine crankshaft.

39