Operation

For Maximum Deck Flotation, place the rollers

one hole position lower. Rollers should maintain

1/4 inch (6.4 mm) clearance to the ground. Do

Not adjust the rollers to support the deck.

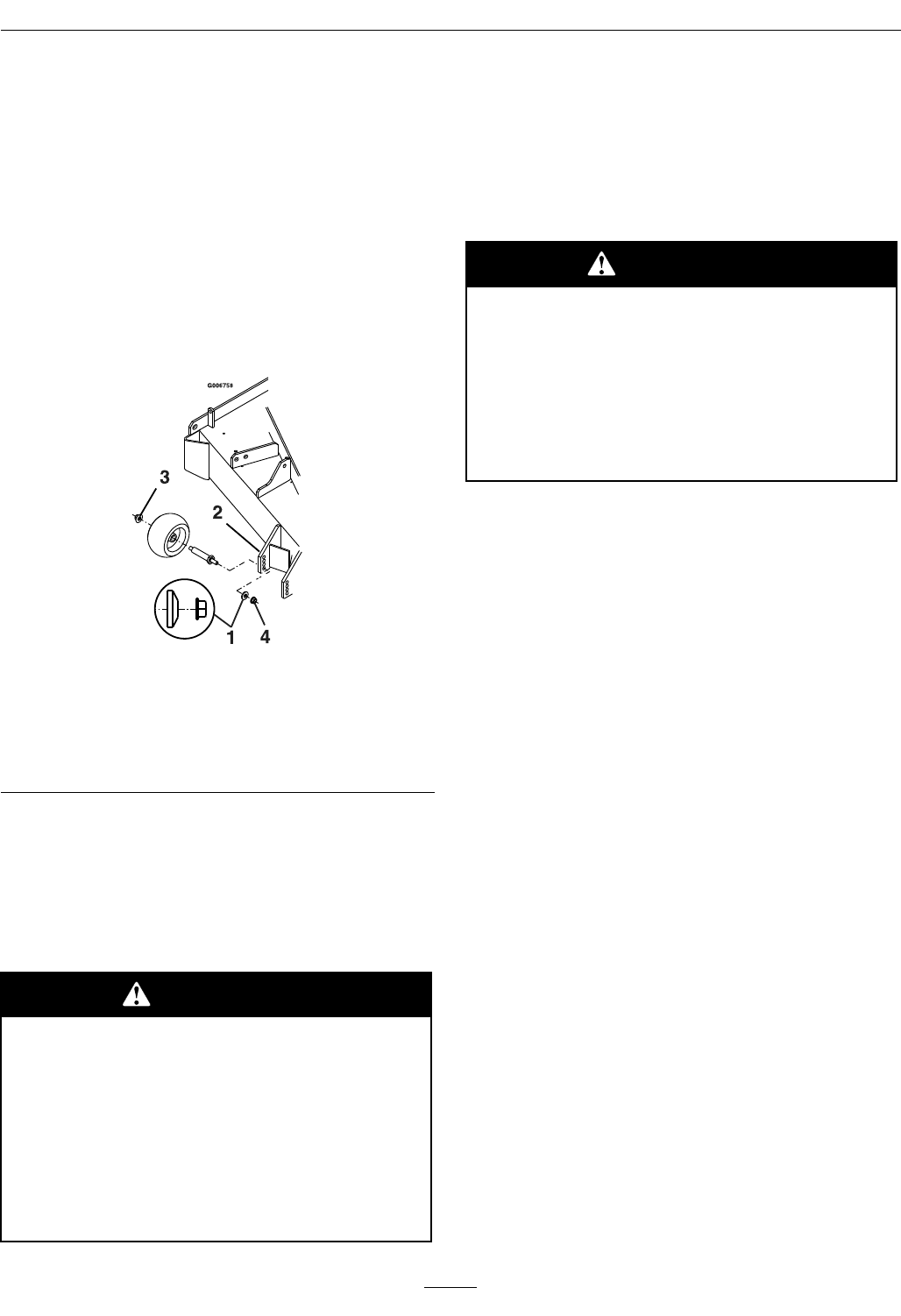

7. Be sure the whizlock nuts are installed with the

spring disc washer between the ange of the nut

and the mounting bracket (see Figure 12).

8. Torque the 3/8-16 whizlock nut to 30-35 ft-lb

(41-47 N-m) (Figure 12).

9. If the 3/8 nyloc nut has been removed, re-install

and torque it to 30–35 ft-lb (41-47 N-m)

(Figure 12).

Figure 12

1. Spring disc washer

(cone towards nut )

3. 3/8 nyloc-torque to 30-35

ft-lb (41-47 N-m)

2. Front right anti-scalp

bracket shown

4. 3/8-16 whizlock nut

torque to 30-35 ft-lb

(41-47 N-m)

Raising the Mower Deck into Service

Position

1. Stop engine, wait for all moving parts to stop,

engage parking brake, and turn key to “run”

position. Do Not start the engine.

WARNING

Incorrectly raising or lowering a mower deck

can be dangerous. A dropped mower deck

can result in a serious injury or property

damage.

• Always raise and lower deck on at, dry

ground, free of any obstructions.

• Always make sure the deck is securely

latched in the “up” or “down” position.

2. Fully extend the cylinder to unload the fold lock

levers.

3. Rotate the fold lock levers, located on each side

of the deck, to the unlocked position (Figure 3).

4. Retract the cylinder and the deck will fold to

approximately 50 degrees.

WARNING

Operating the mower deck in the raised

service position can be dangerous. Engaging

the PTO with a deck in the raised position

can result in a serious injury or property

damage.

Always lower and lock mower deck in the

operation position before engaging the PTO.

Raising the Mower Deck into the

Storage Position

1. Stop engine, wait for all moving parts to stop,

engage parking brake, and turn key to “run”

position. Do Not start the engine.

2. Flip up the oor pan and remove full fold pin.

Retract the cylinder to align holes in oat link

bracket with holes in front frame. (Deck will be

at or near lowest height.) Insert into the bottom

hole of the oat link bracket (see Figure 13).

Lower the oor pan.

15